International Journal of Scientific & Engineering Research, Volume 4, Issue 6, June-2013 1890

ISSN 2229-5518

VIBRATIONAL ANALYSIS OF EXHAUST MUFFLER

Vinay Gupta1, Dhananjay Kr. Singh1, Dhirendra kr. Singh1, Madan Mohan Mishra1, Satish Kumar Dwivedi2, Ajay Yadav2,

1-Student of B. tech (mechanical engineering), Buddha institute of technology, GIDA, Gorakhpur

2- Asst. professor (mechanical engineering), Buddha institute of technology, GIDA, Gorakhpur\

ABSTRACT

Stainless steel is used for variety of automobile components by virtue of its excellent corrosion resistance, heat resistance and good appearance. Currently SUH 409L, SUS 436J1L and SUS 436L are mainly used as materiel for silencer whose corrosion resistance and thermal resistance are good.

The automobile silencer under steady belongs to a popular 2-Wheeler manufacturer in India with the rated HP of the engine up to @7.69HP. The exhaust gases coming out from engine are at very high speed and temperature. Silencer has to reduce noise, vibration. while doing so it subjected to thermal, vibration and fatigue failures which cause cracks. So it is necessary to analyze the vibration which would further help to pursue future project to minimized crack, improving life and efficiency of silencer.![]()

Name | sus436j1L |

Mode type Default failure criterion Yield strength Tensile strength Mass density Elastic module Poisson’s ratio Thermal expansion coefficient | Linear Elastic Isotropic Max Von Mises Stress 2.05e+008 N/m^2 3.9e+008N/m^2 7730Kg/m^3 2.12e+011N/m^2 0.2 1.6e-005/Kelvin |

Name sus409L

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 6, June-2013 1891

ISSN 2229-5518

Mode type

Default failure criterion

Yield strength

Tensile strength

Mass density Elastic module Poisson’s ratio

Thermal expansion

coefficient

Linear Elastic Isotropic

Max Von Mises Stress

1.75e+008N/m^2

3.6e+008N/m^2

7740Kg/m^3

2.06e+011N/m^2

0.24

1.23e-005/Kelvin

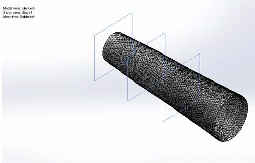

Figure: perforate pipe

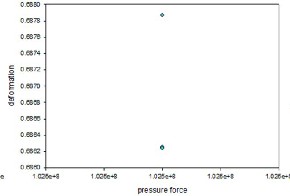

After generating the mesh model of silencer then analysis is done by solid works. The deformation result obtained by solidworks for different

materiel is shown below.

The internal force from the combustion pressure is nearly 102500000 N/M^2 for 2-wheeler vehicle and the analysis noise frequency range is 150 Hz. These two data are required in solid works for pressure distribution on the silencer.

1. The exhaust gas force is worked equally inside the silencer pipe.

2. There is no change in materiel property during analysis.

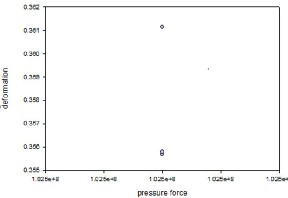

B: Perforated Pipe

After generating the mesh model of resonator by solid

works the deformation result are obtained as

shown below.

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 6, June-2013 1892

ISSN 2229-5518

direction | |||

Deformatio n in Z- direction | 0.49344 | 0.49081 | 0.48933 |

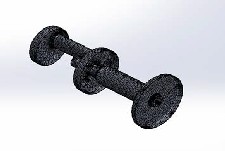

B:Baffle And Mentel pipe:

Figure: maffle and baffle

After generating the mesh model of resonator by solidworks the deformation result are obtained as

shown below.

Result:

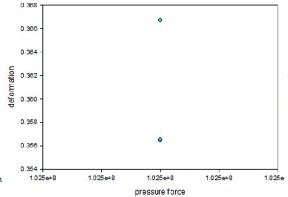

B. Deformation for PERRFORATE PIPE

Material name | sus436j1L | sus409L | sus436LT |

Deformatio n in X- direction | 0.7037 | 0.69936 | 0.69853 |

Deformatio n in Y- | 0.50479 | 0.49237 | 0.49018 |

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 6, June-2013 1893

ISSN 2229-5518

Similarly deformation graph can be draw for

mental and baffle and silencer pipe.

Conclusion:

1.On the basic of vibration analysis of three materials SUS 436J1L have higher deformation then other two material SUS 409L , SUS 436LT and SUS 436LT is the minimum deformation so it is better option for silencer part for manufacturing due to higher life cycle.

2.The value of frequency of materiel SUS 436J1L is the highest at last node of each part of exhaust muffler so it will create more noise so it is not more suitable to reduce the amount of noise emitted by vehicle

References:

[1] Vibrational analysis of automotive Exhaust

Silencer based on FEM and FFT Analyzer.

[2] Automobile Vibrations and Acoutic Noise Reduction via Modal Analysis Technique International journal( 1-3-2012)

[3] IJAUERD Designing and Optimization of

Exhaust Muffler in Automobiles.

[4] On The theoretical vibration analysis of exhaust system

IJSER © 2013 http://www.ijser.org