International Journal of Scientific & Engineering Research, Volume 3, Issue 9, September-2012 1

ISSN 2229-5518

Tungsten-Carbide Composite: A Review

Siddharth Choudhary, Shobhit Singhal, Ujjawal Mayank Srivastava, Pratik Jain, Vikrant Yadav

Abstract - WC alone is very hard and brittle and only when it is used along with a metallic binder like Co, Ti it becomes useful for engineering applications. The composite of cemented carbide formed is known as cermet in which WC is embedded in the matrix of metallic binder (28,29). Given the popularity of WC-Co as a hard and tough material various developments took place which showed that by refining the size of WC particles below 100nm its mechanical, tribological properties could be improved at elevated temperatures.[30,31] The present review paper introduces with various synthesis techniques followed by advanced processing techniques used to produce dense nano composites followed by the latest attempt to develop dense binderless WC based composites.[40-41]

Index Terms— W C, Nanostructure, Metal-Matrix Composites, Cermets, Binderless W C, Ceramics, Nano-Composites.

—————————— ——————————

1 INTRODUCTION

Nano structured materials which are a new class of metal matrix nano composites, consisting of nano scale particles used as reinforcements. Generally micron-sized particles are used to improve the ultimate tensile and the yield strengths of the metal. However, the ductility of the MMCs deteriorates significantly with high ceramic particle concentration [1–3]. It is of interest to use nano-sized ceramic particles to strengthen the metal matrix, while maintaining good ductility, high temperature creep resistance and better fatigue [4, 5]. Various methods are there for producing MMCs, including mechanical alloying [6], ballmilling [7], nano sintering [8].

Like for mechanical alloying, it normally involves

mechanical mixing of metallic and ceramic powders or different metallic powders for fabrication of bulk. Mixing of nano sized ceramic particles is lengthy, energy consuming, and not economical.[9-10] In contrast with mechanical alloying, melt processing which involves the stirring of ceramic particles into melts has some important merits like better matrix–particle bonding, easier control of matrix structure, simplicity, low cost of processing, and nearer net shape. However, it is extremely difficult to distribute and disperse nano-scale particles uniformly in metal melts by mechanical stirring method due to their large surface-to- volume ratio and their low wettability in metal melts, which easily induce agglomeration and clustering [11-13].

2 PROCESSING OF METAL MATRIX COMPOSITES

The selection of suitable process is based on the desired kind, quantity and distribution of the reinforcement components (particles and fibers), the matrix alloy and the application. By altering the manufacturing method, the processing and the finishing, as well as by the form of the

reinforcement components it is possible to obtain different characteristic profiles, although the same composition and amounts of the components are involved.[14]

2.1 Powder metallurgy

It is a forming and fabrication technique consisting of three major processing stages, forming, sintering and finishing by secondary operations. It produce discontinuous fiber reinforced MMCs.

2.2 Diffusion bonding

In this technique layers of metal foil are sandwiched long fibers, and then pressed through to form a composite. Also this technique is used for making multi-layer metal sheets. One of applications is the bi-metal.

2.3 Impregnation process

In this technique a bundle of fibers tightly bound together in cylindrical shape and immersed in a molten metal, which temperature is lower than the softening point of the fibers. The molten metal would be attracted to impregnate and climb-up the voids between the fibers due to capillary action. It is possible to extrude or draw of metal matrix composite to modify the outer shape or cross section, or to reduce the diameter which might be needed to undergo such secondary processes for more than one pass to ensure final dimension and good quality.

2.4 Electrochemical forming

This process is mainly used to reinforce the metal matrix with long continuous fibers. The process depends on aligning the long fibers in a (non-conductive frame) such as plastic frame to hold the long and electrically conductive fibers. All types of metallic fibers as well as graphite fibers that are conductive to electrical currents are used in this process. The frame with the long fibers is immersed in a bath containing a solution of certain chemical compound. Such compounds are used in electroplating, where metallic

IJSER © 2012 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 3, Issue 9, September-2012 2

ISSN 2229-5518

layers are precipitated onto metal surfaces, like Ni-plating, Chrome-plating, or copper plating. This process is quite common in industry. The proper salt is chosen in order to precipitate the desired metallic matrix. A d.c. current is passed, with the proper value of current density for a relatively long period of time. During this the metallic matrix will be precipitated around the fibers, and this precipitation will accumulate and form a plate shape matrix. The density of the matrix would depend on the preparation factors like current density, salt- bath temperature. The resulting sheet composite may treated by secondary forming process to control the final dimensions by rolling. This may also affect the final microstructure and reduce the voids of the bulk of the metal matrix that may form during the precipitation process.

2.5 Plasma spraying methods

This process used only for long fibers of all kinds conductive and non conductive. Molten metal is sprayed onto a continuous fiber substrate.

2.6 Stir casting

This process is used to produce discontinuous reinforced MMCs. . The casting (MMC) can be cast directly or processed with alternative procedures such as squeeze casting.

2.7 Squeeze casting

Squeeze casting or pressure casting are the most common manufacturing variants for MMCs. Molten metal is injected into a form with fibers or particles preplaced inside it. A two-stage process is often used. In the first stage the melt is pressed into the form at low pressure and then at high pressure for the solidification phase. This prevents damage to the preform by too fast infiltration. The squeeze casting permits the use of relatively reactive materials, since the duration of the infiltration and thus the response time, are relatively short. A further advantage is the possibility to manufacture difficultly shaped construction units.

2.8 Physical vapor deposition

The fiber is passed through a thick cloud of vaporized metal, coating it. Melting metallurgy for the production of MMCs is at present of greater technical importance than powder metallurgy. It is more economical and has the advantage of being able to use well proven casting processes for the production of MMCs.

3 HARDWARE USED TO CAST SPECIMENS INTRODUCTION

There are various way to cast specimen as we used nano

powder which was very small in size and it created

problem during casting like proper mixing, uneven distribution along the aluminium matrix. So we used a

special technique discussed further for uniform distribution of nano particles during casting. Following hardware were used during casting.

Induction Furnace

The principle of operation of the induction furnace is the based on the electro-magnetic induction. The alternating current applied to the coil produces a varying magnetic field, which is concentrated within the helical coil. This magnetic field passing through the charge induces secondary current in the charge. The current circulating in the charge produces heat due to electrical (I2R) losses i.e. resistance, which heat the charge and eventually melt it. Induction furnace is best suited for MMCs because the metal rotates at high speed melting which result in self stirring action.

We use induction furnace because of the following reasons: Induction heating is a clean form of heating

High rate of melting or high melting efficiency

Controllable and localized heating

Self stirring action due to spinning of molted metal at high speed

4 DIE USED FOR CASTING

We used a die for casting of Aluminium matrix nano alumina composites instead of sand casting because sand casting results in various defects. Die was made as per experimental requirement .It was made in two parts such that after solidification of specimen it can be split into two part and eject the specimen easily.[15]

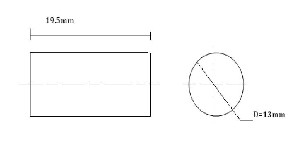

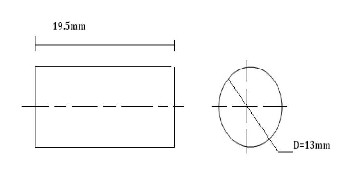

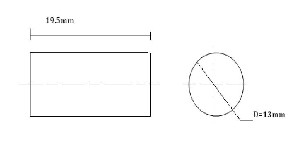

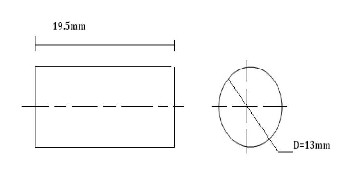

COMPRESSION TEST

The test was done on universal testing machine of 1000kN capacities. The sample is to be compressed between 2 flat platens and the maximum failure load will be recorded (in compression test, the piece of material is subjected to end loading which produces crushing action). The specimen is of 19.5mm length and 13mm diameter.[16]

IJSER © 2012 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 3, Issue 9, September-2012 3

ISSN 2229-5518

L/D=1.5

Figure 4.5 Specification of specimen for compression test

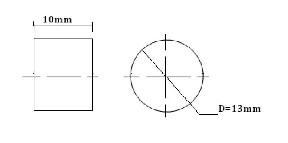

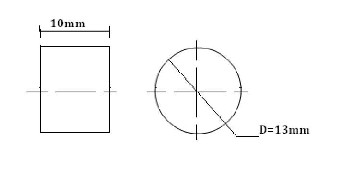

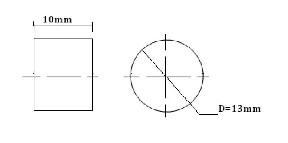

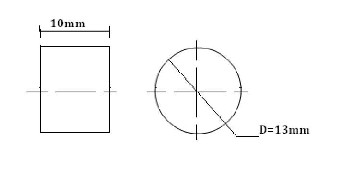

ROCKWELL HARDNESS TEST

Rockwell hardness test was done on Al alloy – nano alumina composite specimen and B scale was used. A 1/16 inch hardened steel ball was used as indenter and the load applied was 100 Kgf. Rockwell hardness testing needs surface preparation (polishing) of the specimen whose hardness is to be measured, therefore the specimen were polished on polishing machine.

Figure 4.7 Specification of specimen used for hardness test

5 EQUPMENT AND TESTING INTRODUCTION

In this chapter the equipment generally used in experiment and testing of properties of WC composite specimen has been discussed. Hardness testing machine normally used to determine hardness of specimen.[17-19]

5.1 Rockwell Hardness Test

The hardness of ceramic substrates can be determined by the Rockwell hardness test, according to the specifications of ASTM E-18. However, the Rockwell hardness test does not serve well as a predictor of other properties such as strength or resistance to scratches, abrasion, or wear, and should not be used alone for product design specifications. The Rockwell hardness test is the most used and versatile of the hardness tests. The chief advantage of Rockwell hardness is its ability to display hardness values directly, thus obviating tedious calculations involved in other hardness measurement techniques. It is typically used in engineering and metallurgy. Its commercial popularity

arises from its speed, reliability, robustness, resolution and small area of indentation.

Figure 4.7 Specification of specimen used for hardness test

6 TESTING OF PROPERTIES

Universal testing machine was used to determine tensile and compressive strength.[20-23]

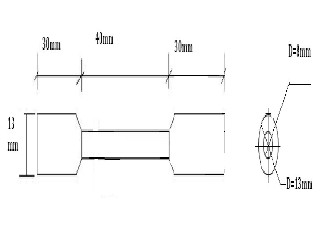

6.1 Tensile Test

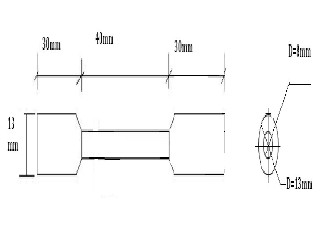

Tensile test helps determining tensile properties such as tensile strength, yield strength, % elongation, % reduction in area and modulus of elasticity. The specimen is of 8mm diameter and 40mm gauge length in the gauge length portion. 13mm is the diameter of the gripping portion which is also 30mm length on either side.

Figure 4.3 Specification of specimen for tensile testing

6.2 COMPRESSION TEST

The test was done on universal testing machine of 1000kN capacities. The sample is to be compressed between 2 flat platens and the maximum failure load will be recorded (in compression test, the piece of material is subjected to end loading which produces crushing action). The specimen is of 19.5mm length and 13mm diameter.

IJSER © 2012 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 3, Issue 9, September-2012 4

ISSN 2229-5518

L/D=1.5

Figure 4.5 Specification of specimen for compression test

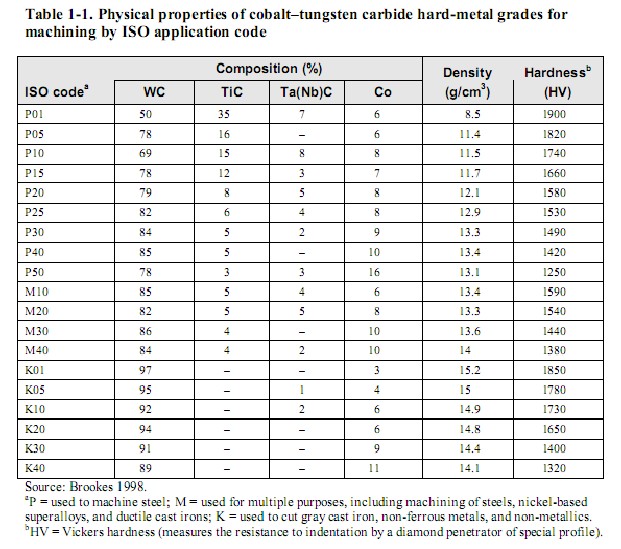

7 SYNTHESIS, PROCESSING AND PROPERTIES OF NANO -STRUCTURED WC BASED CERMETS

WC-Co cermets have been extensively used over the last few decade in various engineering applications like in cutting, drilling, mining, forming tools and wear resistant parts owning to their exceptional high hardness, wear resistance and better toughness than that of other hard materials [42-43]. However over the last decade

substantial efforts have been put in the synthesis and processing of nano structured composites as the mechanical (hardness) and tribological (wear resistance) properties improve significantly when grain size approaches nano scale [42].this surge towards the synthesis of nanostructured composites was met by difficulty in the synthesis of nano-structured particles of size less than

~100nm using conventional techniques [45].

8 SYNTHESIS TECHNIQUES OF NANOSIZED WC-CO POWDER

Conventionally the synthesis of nanosized cemented carbides was carried out using high energy planetary ball mill (HEBM) [44,45,46]. But because of long processing time occurred this process is seldom used on industrial scale . Commercially synthesis of nanostructured composites became popular with the advent of spray conversion process. Developed by Mccandlish and Kear at Rutgers university one of the most commercially used method to produce nano-structured material is spray conversion process(SCP ) which involves building up the nanoscale structure form the molecular level [47].In this an aqueous solution of (NH4)6(H2W12O40)4H2o and CoCl2 or Co(No3)2 or Co(CH3COO)2 is spray dried to get a precursor powder which is reduced and carbonized in a fluidic bed reactor to yield nano structured WC and Co [49,50].

IJSER © 2012 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 3, Issue 9, September-2012 5

ISSN 2229-5518

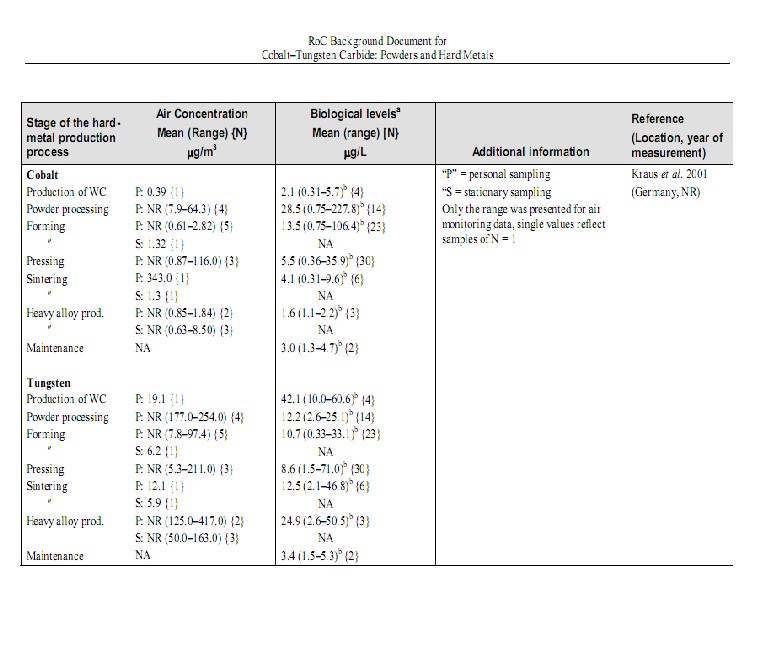

RoC Backgrou11d Doc umen t for

CobaltTu11gste n Car bide: Powde rs. and Hard 'letals.

Step l

Mixed ...t.tl-------1 Caroon

Hnt!d Inh:ydi'qgm

lilti,4SO- l

:--------' --------...Mixed

L .l

t1 I Orpnicso1vmta.  l

l

Dried

I fiobbrd ·powdn-1

Step 2

Step3

Presl:ntu«<:htaled In h)d,.n

ar¥acoum at

Sha]ltlli

Sinkrect hatrd bt byclro&m

o.r ftOIIIJD 111 1.350-J.55IJ'IC

SandbiDIH

Shot blasted

Br'PI:d ln!o holder$

wtthlloxes

Ground wUh cliimwDd_ or carbot undu m wbeeb

IJSER ©2012

http://www ijserora

International Journal of Scientific & Engineering Research, Volume 3, Issue 9, September-2012 6

ISSN 2229-5518

Ref. Hard_MetalsBD-FINAL(SCG-17Mar09)

In another method plasma assisted chemical vapor synthesis, vapor phase precursor of tungsten hexachloride WCl6 is reduced and then subsequently carburized using CH4 as carburizing agent to produce nano-structured WC powder. [52,53] More recently a thermochemical single step displacement reaction processing route to produce finer grains <10nm was developed in which carburization of ammonium tungstate or tungsten oxide is done in a single operation via slow heating to ensure balance between reduction and carburization [53] Another very attractive method to produce particle of size <30nm of high

purity using metal organic precursor of solid tungsten hexa carbonyl (W(Co)6) and carbon monoxide (CO)gas is chemical vapour synthesis .The precursor was decomposed into W & 6(Co) at 1200 c .Further carburization with C from dissociation of CO gas at 600-8000C led to synthesis of WC1-x nanopowder. When measured by XRD and TEM it was realized that with increase in reaction temperature from 600 to 10000C the size of powder reduced from 53nm to 28nm[54].

IJSER © 2012 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 3, Issue 9, September-2012 7

ISSN 2229-5518

Adapted from Kusaka et al. 1986

9 PROCESSING TECHNIQUES OF NANOCRYSTALLINE CEMENTED CARBIDES

WC-Co cermet in which WC is embedded in matrix of Co metallic binder is prepared by liquid phase sintering at a temperature of 14000c.[55] Co aids in the liquid phase sintering and lowers the sintering temperature .However controlling the grain growth and retaining nanoscaled grain sizes has been the barrier in the sintering of tungsten carbide. [55,56]. The grain of WC in sintered phase becomes coarser as compared to presintered phase due to coarsening ,the rate of which increases with finer WC particles. Experiments have shown that grain growth of nano sized particles occurs during two stages 1.) During the initial heat up period 2.) At the final sintering temperature [58]. Most of the grain growth occurs during the early stage of liquid phase sintering by coarsening or coalescence (solution reprecipitation). During coalescence orientation of grains changes by rotation & when the rotation of two fine grains match they form a coarser grain. This process is favoured by finer grain size. Later grain growth occurs at isothermal hold by grain boundaries migration or oswald ripening with dissolution of smaller WC grain and reprecipitation on larger grains in binder phase Co. The reduction in surface energy of the solid particles is the major component of the driving force for small grains to dissolve and large grains to grow [58-60].

Grain growth inhibitors are used for preventing grain growth during heat up for nanosized powders.in many studies vc has been considered the most effective grain growth inhibitor due to its high solubility and mobility in liquid cobalt phase. Higher solubility of an inhibitor in Co liquid phase causes less solubility of w in it & it leads to finer grain structure. Addition of vc changes the interfacial and surface energies of WC grains & make their surface shape faceted from equiaxial which ultimately reduces their ability to coalesce as faceted shaped grains does not match up with other grains of same orientation .thereby reducing the abnormal grain growth during heat up stage[61,62,63,64] vc is found to prevent grain growth not only at the liquid phase sintering stage but also at low solid state temperature grain size can be reduced to as low as

200nm with 1% vc addition.[65,66]

It has been observed that grain growth starts at 800c and rapid grain growth occurs between 1000-1200c, but the addition of 1% vc in WC-10co prevents grain growth until

1400c.initial grain growth can be minimized using vc.[65] a recent study focused on the method of adding of the inhibitor to the WC-Co composite. The results show that the WC grain sizes of sintered alloys are finer than those of admixed samples and hence they possess high hardness. As

IJSER © 2012 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 3, Issue 9, September-2012 8

ISSN 2229-5518

the chemically doped vc restrains abnormal grain growth more effectively than admixed vc.[64]

Using conventional sintering techniques desired density cannot be achieved.

So in order to develop dense bulk nano structuredWc

cemented carbides the effect of different compacting

pressure and heating schedule during sintering was

studied and it was found that hardness and density

increases with compacting pressure and heating schedule with holding steps is found to be more effective than direct heating without any holding steps[65]

To make it useful on commercial scale various investigations have been carried out which revealed that electric assisted sintering techniques fast which involves application of electric field with uniaxial pressure aids in getting highly dense nano-composites with minimum coarsening at lower sintering temperature along with short holding time and rapid heating rate. One of the variants of fast is sps spark plasma sintering [67,68,69] .

As the temperature in sps is increased the densification

increases. Also the grain size also increases with increasing

temperature as the abnormal grain growth

increases[70].average homogeneous particle sizes as low as

300nm can be achieved by sps technique.[72] by using sps the WC-Co composite can be densified at a much lower temperature(1200) than that of conventional liquid phase sintering under a pressure of 40 mpa.[70]grain growth can be controlled in spark plasma sintering due to the reduction in sintering temperature to 12800c and short holding time of 5 min as compared to conventional sintering processes where the temperature is of the range of 1380-1450.[55]. WC

–Co can be rapidly consolidated by spark plasma sintering process and almost full densification can be achieved.WC-6

wt % Co can be obtained within 12 minutes by sps.[71]. The only problem with sps was that w2c phase was formed which contributes to abnormal grain growth. The formation of w2c can be mitigated by the addition of extra carbon.[72]the amount of w2c is also dependent on the initial particle size. In finer powders the amount of w2c phase produced would be larger.[72]It has generally been observed that the sintering of nanocrystalline WC–Co powders over 90% densification can be achieved via solid state sintering below 12800c and it increases with decreasing particle size.[67].higher density can be achieved in the sintering of WC-Co powders by increasing the temperature in the sintering process. Also densification in nanoscaled powders occurs at a much lower temperature (about 160 degrees less) than in case of micron sized powders.

High-frequency induction-heated sintering (hfihs) and pulsed current activated sintering (pcas) have been used to densify WC–8 wt.%Co composites of various WC powder sizes [84] the recent high-frequency induction- heated

sintering (hfihs) technique has been shown to be effective in the sintering of nanostructured materials in very short times (within 1 min)[83] using high-frequency induction heated sintering, the rapid consolidation of binderless WC and WC-Co hard materials can be accomplished using ultra fine powders of WC and WC-Co. Nearly fully dense WC and WC-Co could be obtained in less than 2 min. The densification temperature of WC was significantly reduced by the addition of Co.[85]. Increasing the temperature of sintering upto 14000c can increase the densification of WC. Also there is significant increase in the density by increasing pressure upto 20MPa[86]

Densification greater than 99% was achieved using conventional liquid phase sintering for 92Wc–8co (wt%) when sintered at 1400c for 1h. However when pre sintering of composite in solid state was carried out density greater than 99% is achieved by sintering for 30min only at sintering temperature of 1400c .thereby reducing the time period of liquid phase sintering .so it is possible to sinter to high density while avoiding coarsening of grains in nano composites by introducing a pre sintering step

[77]

10 PROPERTIES OF WC BASED CERMETS

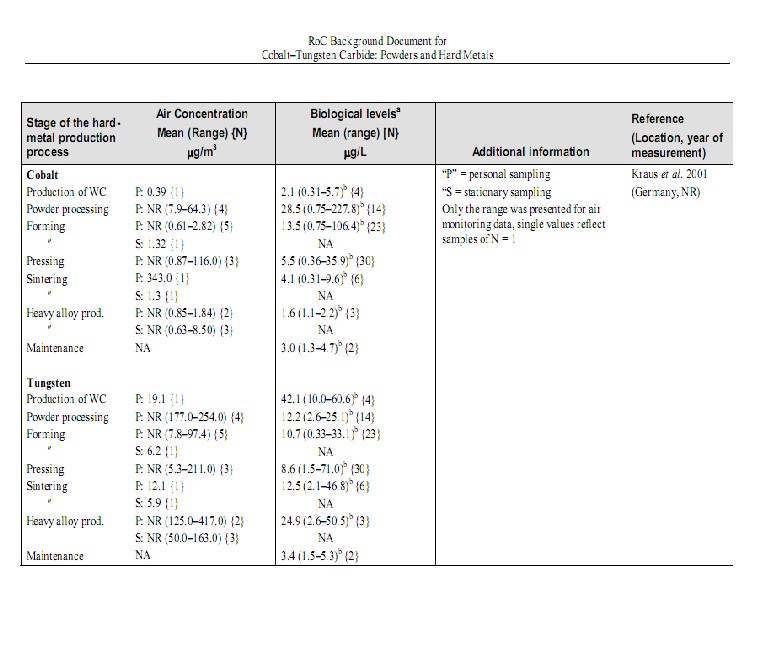

The mechanical properties of nanocrystalline materials are affected by both grain size and grain orientation.[78]it has been observed that the value of vickers hardness decreases as the particle size increases.[79,80,81,82] the hardness can be determined by the grain size from the deduced hall petch relationship. Also the addition of grain growth inhibitor like cr3c2 can lead to an increase in hardness as it inhibits grain growth and a smaller grain size has a higher hardness.[70] the hardness decreases on increasing the Co content.[80]it has been observed that the fracture toughness increases with increasing binder mean free path, but nanocrystalline WC-10co exhibited lower fracture toughness than the conventional WC-Co. fracture toughness in WC-Co is calculated by the cracks produced from indentations under large loads. [73]the fracture toughness decreases with decreasing the particle size. The fracture toughness of nanocrystalline WC-Co is related to the hcp/fcc ratio of Co binder phase. Higher hcp/fcc ratio leads to higher fracture toughness in WC-Co tungsten carbides.[81] the specific wear rate decreases by decreasing the Co content and grain size hence the wear resistance increases which is the inverse of specific wear rate.the specific wear rate also increase by increasing mean free path while hardness decreases.[80]

IJSER © 2012 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 3, Issue 9, September-2012 9

ISSN 2229-5518

RoC Backgrow1d Docw11ent for

CobaltTw1gsten Ca r bide: Powders and Hard Metals

Co = cobalt; N = number of samples; NA = not assessed; NR = not reporteW = tungsten.

l Cobalt levels unlm othenvise noted.

IJSER ©2012

http://www ijserora

International Journal of Scientific & Engineering Research, Volume 3, Issue 9, September-2012 10

ISSN 2229-5518

11 DEVELOPMENT OF BINDERLESS WC-BASED CERAMICS/ COMPOSITES

The binder phase property plays the vital role for cemented carbides. It increases the materials toughness by introducing a metallic component into the microstructure

. It controls the bonding between WC grains and it

make possible the sintering to a completely dense body.[83]

The metallic binder phase is responsible for hinder the performance of such materials, particularly in demanding good high temperature properties and high hardness.[84] Moreover, the use of a binder results in degradation in the corrosion and oxidation resistance. Hence, the performance

of the cemented carbide based tools is limited by the metallic phase. It also restrict the life of the instruments due to excessive wear or corrosion.[85] Hence, both the problems of densification and brittleness will be solved simultaneously under the development of binderless WC which require material design.[86]

The efficient field activated spark plasma sintering (SPS) technique that can successfully consolidate ceramics to near theoretical density [87]. The Tungsten Carbide grains are under compression after the sintering process due to the dissimilarity in thermal expansion of WC and Co, which is useful for the mechanical properties of the cemented carbide. Lately, a new technique was adopted known as the high-frequency induction heating sintering

IJSER © 2012 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 3, Issue 9, September-2012 11

ISSN 2229-5518

(HFIHS), has been used to synthesize and densify the materials from the elemental powders or to consolidate some ultra fine materials within few minutes. It was investigated that the sintering of WC without the use of a binder by the HFIHS method. The goal of this technique used is to produce dense and fine grained binderless WC hard material. Furthermore, it was also observed that effect of total power capacity output i.e. the induced current and the size of starting particle on the mechanical properties and sintering behavior of binderless WC. [88,89]

The densification of binderless submicron WC was achieved by using ultra fine powders with the size of 0.4 m of pure WC with the support of newly fast sintering method (HFIHS). Nearly fully dense WC could be acquired within 1.98 min. [90]Under these conditions, the grain size of the sintered WC could be about 380nm which indicates the absence of grain growth during sintering. Higher output of total power capacity would yield into higher densification rates and higher rates of temperature increase. More finer the initial WC grain size more are the mechanical properties and more the final density would be. For specimen sintered under 60MPa pressure and 90% output of total power capacity (15 kW) using 0.4 m WC powder the fracture toughness and hardness values obtained were 7.1MPam1/2 and 2854 kgmm−2 respectively.[91]

The spark plasma sintered at a temperature range from

1550 to 1800 8C without a holding time at sintering

temperature under vacuum in order set up the sintering conditions for WC (4.06 mm particle size). The shrinkage of

WC powder compact starts at 1200 8C, increases with increased temperature and ends at 1600 8C.If the sintering temperature is higher than1700 8C, the full density of WC is obtained without holding time i.e. heating at the sintering temperature followed by immediate cooling.[92] With increasing the sintering temperature from 1550 to 1700 8C the amount and size of pores within sintered WC decreases. Although, the amount and size of pores are not different between WC sintered at 1700 and at 1800 8C.Regardless of the sintering temperature, grain size of WC is almost 5 mm. This effect shows that short sintering time, such as heating to sintering temperature and immediately cooling, can produce fine WC sintered body when sintered at 1700

8C.[93]

The amount of pores decreases with the formation of WC grain boundaries as the initial WC powder size increases. The WC carbon content sintered from 0.57 mm powder is much lower than that of 4.06 mm. At SPS temperatures of

1700 and 1800 8C, if the holding time is over 1 min. the WC

spark plasma sintered from 4.06 mm powders shows

unusual grain growth. This result shows it was

decarbonized during the sintering process which results in a formation of W2C phase .The effect of holding time along with the addition of C which causes abnormal grain growth should be reduced as much as possible. If a carbon layer is not inserted within the WC powder compact, there is no abnormal grain growth under the same SPS process conditions.

IJSER © 2012 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 3, Issue 9, September-2012 12

ISSN 2229-5518

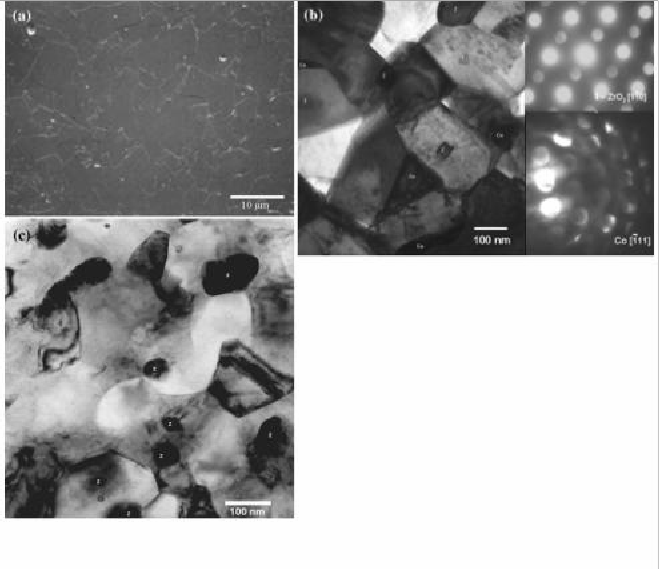

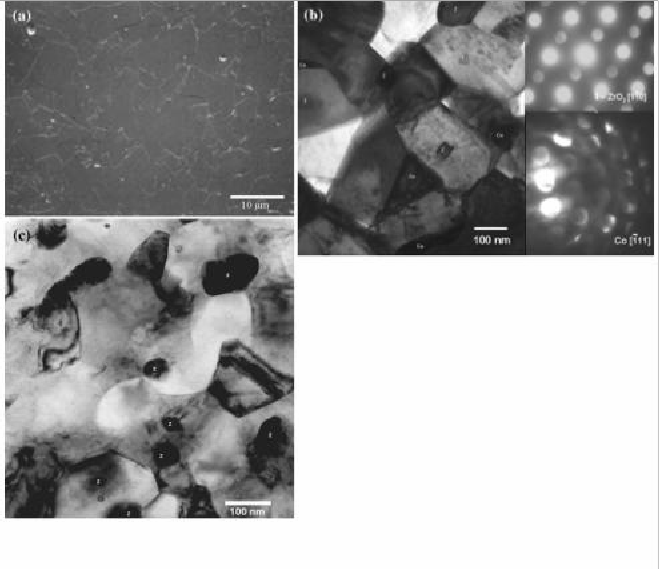

Fig. 8 a SEM image of monolithic WC sintered via SPS at 1700 °C[73]; bright field TEM micrographs of b WC–4 wt% ZrO2–2 wt% Co nanocomposite and c WC–6 wt% ZrO2 [28]

El-Eskandarany fabricated WC–18 % MgO nano/nanocomposite, characterized by the nanosized second phase particles (MgO ˜50 nm) ) as well as nanosized matrix grains (WC ˜25 nm), using PAS in order to address the issue of brittleness associated with binderless monolithic WC.

Larger composite powder particles are formed by reactant materials of WO, Mg and C powders which are agglomerated during the first few kiloseconds (0 to 3.6 ks). The fracture toughness would be increased if the nanocrystalline grains of MgO are kept in the matrix of WC.[94] This nanocomposite (WC/MgO) material can combine high hardness value with a high fracture toughness. The nano scale grains (WC/MgO) have present unique properties to attain higher hardness and toughness combinations in contrast to the commercial microns grained structure of WC/Co composites. It also shows that

both WC and WC/MgO materials preserve their nanocrystalline properties after sintering. [95]This is ascribe to the applied consolidation step (PAS). Micro discharge takes place when the direct current pulse voltage is applied to the powder, generating a plasma. For this reason, the sintering takes place in a short time when the atoms on the surface of each particle are activated. Correspondingly, grain growth can be minimized during sintering [96].

At room temperature, refractory materials of nanocrystalline WC and nanocomposite WC–18 at% MgO powders have been fabricated by ball-milling elemental powders of WO , Mg and C. Using PAS, both materials are separately consolidated into full dense bulk samples. This consolidation step does not show large grain growth, and the compacted as consolidated specimen still maintain their nanocrystalline properties. [97]

IJSER © 2012 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 3, Issue 9, September-2012 13

ISSN 2229-5518

The use of ZrO2 as a ceramic sinter is specific interesting in view of the fact that ZrO2 is thermal and electrical isolator and is not susceptible to electrochemical corrosion. It is suppose to increase the fracture toughness due to transformation toughening and generally not soften at high temperatures. By lowering the temperature in the presence of ZrO2 which acts as a sintering additive so to achieve full densification[98].

The replacement of the metallic binder (Co) phase with ZrO2 nanoparticles suppressed the formation of ‗‗truncated trigonal prism‘‘-shaped WC grains after SPS processing. Moskała and Pyda11 eventually reported that ZrC is formed from the reaction between WC and ZrO2 when pressureless sintering is done for 1 h at ≥1750 ◦C. [99]The ZrO2 particles were maintained in the nanosized regime (40–80 nm). They were allocated uniformly along the matrix (WC) grain boundaries and within the matrix grains (B0.2–0.3 mm) of the SPS-processed inter/intragranular nanocomposites (WC–6 wt% ZrO2, WC–5 wt% ZrO2–1 wt% Co, and WC–4 wt% ZrO2–2 wt% Co).Moreover, a heap of the ZrO2 particles was noticed in the higher ZrO2 (10 wt%)containing nanocomposite.[100]

In specific, the highest average flexural strength value has been noticed which is 18% improvement for the WC–6 wt% ZrO2 nanocomposite above that of the W/Co cermet .The ZrO2-containing nanocomposites possess either superior (WC–5 wt% ZrO2–1 wt% Co, WC–4 wt% ZrO2–2 wt% Co, WC–10 wt% ZrO2B23 GPa) or similar (W6ZrB20 GPa) hardness with respect toWC–6 wt%Co cermet is explained by the microhardness measurements. The WC–6 wt% ZrO2 nanocomposite acquire a high fracture toughness (SEVNB) of B10 MPa m1/2which is only marginally lower (by B16%) than that of the reference W6Co cermet. Moreover, additional improvement in fracture toughness was not notice on partially replacing the (6 wt %) ZrO2 with Co (up to 2 wt%) or increasing the ZrO2 content to 10 wt% . As a matter of fact, presently developed WC-ZrO2-(Co) nanocomposites achieve the best combination of mechanical properties amongst the different ceramic nanocomposites developed till date. Based on the presence of compressive residual stress in the matrix, it is assumed that estimates of toughness increment are found to be not importance with reference to the high toughness of the newly developed WC-based ceramic nanocomposites. [101]Transformation toughening effect of the ZrO2 particles within the WC matrix has been noticed is one of the toughening mechanisms responsible for the considerably high fracture toughness of the presently developed WC– ZrO2 (-Co) nanocomposites. Arising from change in fracture mode from inter granular (for W6Co cermet) totrans granular in the presence of nanosized ZrO2 particles gives other toughening mechanisms.Crack deflection by the ZrO2 particles also leads to high toughness in WC- based nanocomposites. .Hence, it must be known that when there is full replacement of Co binder

phase by ZrO2(6 wt%), it leads to the maximum improvement in strength, with only modest reduction in fracture toughness. The nanosized ZrO2 particles also helping attaining improved tribological properties, which is important with respect to most of the commercial applications of WC-based materials[102].

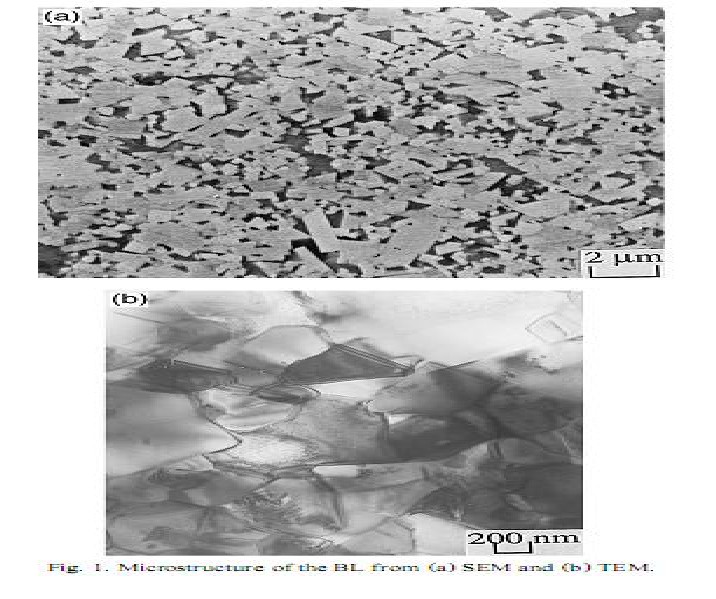

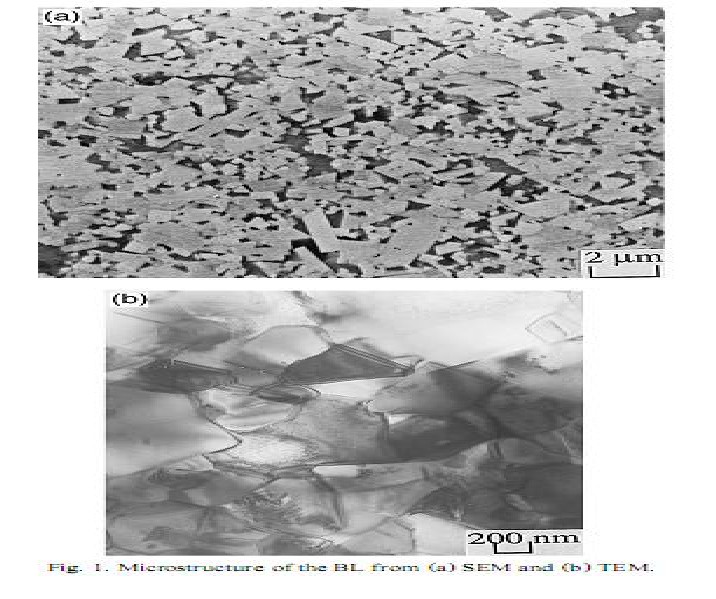

The tribological properties of a binderless carbide have been estimated in sliding wear and abrasion tests. The reference materials were used are Conventional cemented carbides and ceramics. The worn surfaces were examined with energy dispersive X-ray spectroscopy and EDX scanning electron microscopy SEM. To analyze the microstructure, Transmission electron microscopy TEM and SEM were used as shown in fig. The wear rates were in between those of the ceramics and conventional cemented carbides, in abrasion. [103]Grooving of tungsten carbide grains and removal of titanium carbide were favored by the main wear mechanisms. It did not show any transitions from low to high wear levels in dry sliding tests with reference to ceramics. Water lubrication reduced the friction much better as compared to the dry tests for all materials. Furthermore the friction coefficient is reduced by the lubrication with an acidic water solution. In general, water lubrication decreases the friction of ceramic materials. Both wear and friction properties of ceramics are strongly influence by the pH of water solutions. The Co binder phase may be extruded to the surface followed by microfracturing of the carbide grains during high loads and low sliding speeds .Mild wear occurs only at low loads and speeds. Worn surfaces show no proof of plastic deformation or fracture.[104]

As a result of an increased micro toughness of the surface region, it has also been view that the extrusion of binder phase towards the surface decreases the rate of wear for conventional cemented carbides. The grooving and surface shearing disarrange the carbide grains and extrude Co, leaving the grains unsupported to fracture, slip and fall out of the surface in abrasion.[105] The relation between the dimensions of the material‘s microstructure and the size of the abrasive grits is also important for the wear properties. The abrasion tests were also performed with both silica and diamond as abrading particles , both dry and lubricated the sliding wear tests were conducted. With the diamond abrasives, it showed similar load specific wear rates, about

40% higher than the conventional cemented carbides. Silica

gave constantly lower wear rates than diamond, the

difference being 40%.

IJSER © 2012 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 3, Issue 9, September-2012 14

ISSN 2229-5518

It was worn by relatively ductile grooving of tungsten carbide and preferential removal of g-phase grains in abrasion. [106]The wear rates and friction coefficients for the binderless material were comparable with the Co- bonded cemented carbide in dry sliding. No higher level transition wear rates could be found. As compared to dry tests, water lubrication reduced the friction coefficient. It

may be an alternative to conventional cemented carbides for use in sliding applications preferably in corrosive environments.

IJSER © 2012 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 3, Issue 9, September-2012 15

ISSN 2229-5518

[17] D. J. Lloyd, Int. Mater. Reviews, 39: 1 (1994).

[18] J. J. Stephens, J. P. Lucas, and F. M. Hosking, Scripta

Metall., 22: 1307 (1988).

REFERENCES

[1] R.G. Reddy, Rev. Adv. Mater. Sci. (2003)121.

[2] Y.C. Kang, S.L.I. Chen, Chem. Phys. 85 (2–3)(2004)438–

443.

[3] E.M. Maik, O. Beort, S. Kleiner, U. Vogt, Compos.Sci.Technol.679 (11–12)(2007)2377–2383.

[4] K. Akio, O. Atsushi, K. Toshiro, T. Hiroyuki, J. Jpn. Inst. Light Met. 49 (1999)149–154.

[5] K.M. Mussert, W.P. Vellinga, A. Bakker, S. VanDerZwaag, J. Mater. Sci.37 (2002)789–794.

[6] D.M. Lee, B.K. Suh, B.G. Kim, J.S. Lee, C.H. Lee, Mater.Sci.Technol.13 (1997)590.

[7] V. Laurent, P. Jarry, G. Regazzoni, D. Apelian, J. Mater. Sci.27 (1992)447.

[8] R.A.Saravanan, M.K.Surappa, Mater.Sci.Eng.A276 (2000)108.

[9] J. Wadsworth and T. G. Nieh, Mater. Sci. & Eng., A166:

97 (1993).

[10] M. W. Mahoney and A. K. Ghosh, Metall. Trans. A,

18A: 653 (1987).

[11] M. Mabuchi, K. Higashi, Y. Okada, S.Tanimura, T. Imai, and K. Kubo, Scripta

Metall., 25: 2003 (1991).

[12] M. Mabuchi, K. Higashi, Y. Okada, S.Tanimura, T. Imai, and K. Kubo, Scripta

Metall., 25: 2517 (1991).

[13] T. G. Nieh, C. A. Henshall, and J. Wadsworth, Scripta

Metall., 18: 1405 (1984).

[14] M. Y. Wu and O. D. Sherby, Scripta Metall., 18: 773 (1984).

[15] R. S. Mishra and A. K. Mukerjee, Scripta Metall., 25:

271 (1991).

[16] M. Hunt, Materials Eng., 12: 45 (1989).

[19] N. A. Travitzky, J. Mater. Sci., 36: 4459 (2001).

[20] H. Lu, J. Hu, C. Chen, H. Sun, and X. Hu, Ceramics

International, 31: 481 (2005).

[21] M. Ferry and P. R. Munroe, Mater. Sci. & Eng., A358:

142 (2003).

[22] X. X. Yu and W. B. Lee, Composites, A31: 245 (2000).

[23] P. Katiyar, ―Processing,Microstructural, and Mechanical Characterization of Mechanically Alloyed Al- Al2O3 Nanocomposites‖, Masters Thesis, University of Central Florida (2004).

[24] G.-Q. Shao, X.-L. Duan, J.-R. Xie, et al., Rev. Adv. Mater. Sci. 5(4) (2003) 281–286.

[25] E. Lassner, W.-D. Schubert, Tungsten-properties, Chemistry, Technology of the Element, Alloys and Chemical Compounds, Kluwer Academic Publishers/Plenum Press, London, 2000

[26]Hwan-Cheol Kim , In-Jin Shon, Jin-Kook Yoon, Jung- Mann Doh, International Journal of Refractory Metals & Hard Materials 25 (2007) 46–52

[27] D.K. Shetty, I.G. Wright, P.N. Mincer, A.H. Clauer, Journal of Materials Science 20 (1985). 1873–1882.

[28]Mohan K, Strutt PR. Observation of Co nanoparticle dispersions in WC nanograins in WC–Co cermets consolidated from chemically synthesized powders. Nanostruct Mater 1996;7:547–55.

[29]Lenel FV (1980) Powder metallurgy principles and applications. Metal Powder Industries Federation, Princeton, NJ, p 383

[30]Mukhopadhyay A, Basu B (2007) Int Mater Rev 52:257 [31]Mukhopadhyay A (2008) Tribol Mater Surf Interfaces

2:169

[32]Zhang FL, Wang CY, Zhu M (2003) Scripta Mater

49:1123

[33]Cha SI, Hong SH, Kim BK (2003) Mater Sci Eng A

351:31

[34]Kim HC, Jeong IK, Shon IJ, Ko IY, Doh JM (2007) Int J Ref Met Hard Mater 25:336

IJSER © 2012 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 3, Issue 9, September-2012 16

ISSN 2229-5518

[35]Sivaprahasam D, Chandrasekar SB, Sundaresan R (2007) Int J Ref Met Hard Mater 25:144

[36]Suzuki H (1986) Cemented carbide and sintered hard materials. Maruzen, Tokyo, Japan, p 262

[37]Suzuki H, Hayashi K, Yamamoto T, Nakajo NJ (1966) J Japan Soc Powder Powder Metall 13:290

[38]Masumoto Y, Takechi K, Imasato S (1986) Nippon

Tungsten Rev 19:26

[39]Kim HC, Shon IJ, Garay JE, Munir ZA (2004) Int J Ref

Met Hard Mater 22:257

[40]Kim HC, Shon IJ, Yoon JK, Lee SK, Munir ZA (2006) Int

J Ref Metal Hard Mater 24:202

[41]D.k. shetty, i.g. wright, p.n. mincer, a.h. clauer, journal of materials science 20 (1985) 1873–1882

[42]d.g.f. o‘quigley, s. Luyckx, m.n. james, an empirical ranking of a wide range of WC–Co grades in terms of their abrasion resistance measured by the astm standard b 611-85 test, int. J. Refract. Met. hard mater. 15 (1997) 73–79.

[43]scussel hj (1992) friction and wear of cemented carbides. Asm handbook, vol 18. Asm international, materials park, oh, p 796

[44]sun j, zhang f, shen j. Mater lett 2003;57:3140–8.

[45]el-eskandarany ms, mahday aa, ahmed ha, amer ah. J

alloys compd 2000;312:315–25

[46]toth le. Transition metal carbides and nitrides. New york: academic press; 1971.

[47]McCandlish, l. E., kear, b. H. & bhatia, j., spray conversion Process for the production of nanophase composite Powders. Us pat. App. S.n. 433 742.

[48]Z. Zak Fang , Xu Wang, Taegong Ryu, Kyu Sup Hwang, H.Y. SohN Int. Journal of Refractory Metals & Hard Materials 27 (2009) 288–299

[49]b.k. kim, g.h. ha, d.w. lee, j. Mater. Process. Technol. 63 (1997) 317

[50]d.kim and a. Accary: mater. Sci. Res. Vou3 (1980), 235 [51]nanograined WC-Co composite powders by chemical

vapor Synthesis

[52]ryu t, sohn hy, hwang ks, fang zz (2008) j mater sci

43:5185. Doi:10.1007/s10853-008-2741-8

[53]gao l, kear bh (1997) nanostruct mater 9:205

[54]synthesis of nanosized tungsten carbide powder by the

Chemical vapor condensation process

[55] wenbin liu, xiaoyan song , jiuxing zhang , fuxing yin , guozhen zhang journal of alloys and compounds 458 (2008) 366–371

[56]z. Fang, p. Maheshwari, x. Wang, h.y. sohn, a. Griffo, r. Riley interntional journal of refractory metals & hard materials 23 (2005) 249–257

[57]w. D. Schubert, a. Bock & b. Lux int. J of refractory metals & hard materials

[58]Xu Wang, Zhigang Zak Fang , Hong Yong Sohn ,Int

Journal Ref Metals & Hard Materials 26 (2008) 232–241

[59] Rahaman MN (2003) Ceramic processing and sintering,

2nd edn. Marcel Dekker Inc, New York, USA

[60]Wang X, Fang ZZ, Sohn HY (2008) Int J Ref Met Hard

Mater 26:232

[61]A. Adorjan a, W.D. Schubert a, A. Schön b, A. Bock b, B. Zeiler b ,International Journal of Refractory Metals & Hard Materials 24 (2006) 365–373

[62] SUN Lan', JIA Cheng-chang', LIN Chen-guang2 , CAO Rui-jun',Proceedings of Sino-Swedish Structural Materials Symposium 2007

[63] Johannes Poetschke , Volkmar Richter, Roland Holke

,Int. Journal of Refractory Metals and Hard Materials 31 (2012) 218–223

[64] pang cholsonga, luo jia, and guo zhimengarare metals

vol. 30, no., p. 20. H. C. Kim, i. J. Shon, and z. A. Munir, j. Mater. Sci. 40

[65] xu wang, zhigang zak fang , hong yong sohn international journal of refractory metals & hard materials

26 (2008) 232–241

[66]Lee GH, Kang S (2006) Int J Ref Met Hard Mater 419:281 [67]Seung I. Cha a, Soon H. Hong a, Byung K. Kim b

Materials Science and Engineering A351 (2003) 31/38

[68]Jinfeng Zhao, Troy Holland, Cosan Unuvar 1, Zuhair A. Munir Int. Journal of Refractory Metals & Hard Materials

27 (2009) 130–139

[69]Z. Zak Fang , Xu Wang, Taegong Ryu, Kyu Sup Hwang, H.Y. Sohn Int. Journal of Refractory Metals & Hard Materials 27 (2009) 288–299

[70]tao li , qingfa li , j.y.h. fuh, pohching yu , c.c. wu, materials science and engineering a 430 (2006) 113–119

IJSER © 2012 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 3, Issue 9, September-2012 17

ISSN 2229-5518

[71]hyun-kuk parka, hee-jun youna, seung-min leea, hee- seonbangb and ik-hyun oha, powder technology 122 ž2002.

54–60

[72]h. C. Kim, i. J. Shon, and z. A. Munir, j. Mater. Sci. 40

[73] hwan cheol kim , in kyoonjeong, in jin shon, in yong ko, jung mann doh, international journal of refractory metals & hard materials 25 (2007) 336–340

[74] hwan cheol kim , in kyoonjeong, in jin shon, in yong ko, jung mann doh, international journal of refractory metals & hard materials 25 (2007) 336–340

[75]hwan-cheol kim1, in-jin shon1, in-kyoon jeong1, in- yong ko1, jin-kook yoon2, and jung-mann doh, metals and materials international, vol. 13, no. 1 (2007), pp. 39~45

[76]liu xiang- qing, lin tao, guo z h i - rneng, cui feng- e, luo proceedings of sino-swedish structural materials symposium 2007

[77]Dong-Yeol Yang, Suk-Joong L. Kang, Int. Journal of

Refractory Metals & Hard Materials 27 (2009) 90–94

[78]ying wang , jianqiu zhou t.d. shen, david hui, shu zhang computational materials science 58 (2012) 175–182

[79]t.s. srivatsan, r. Woods , m. Petraroli, t.s. sudarshan

powder technology 122 ž2002. 54–60

[80]hiroyuki saito , akira iwabuchi, tomoharu shimizu wear 261 (2006) 126–132

[81]international journal of refractory metals & hard materials 19 �2001) 397±403seung i. Ch, soon h. Hong , gook h. Ha , byung k. Kim

[82]seung i. Cha, soon h. Hong, gook h. Ha and byung k. Kim scripta mater. 44 (2001) 1535–1539

[83] H. Engqvist , G. A. Botton , N. Axdn , S. Hogmark

(Int J Ref Met Hard Mater 16 (1998) (309-313))

[84]H.W. Hugosson , H. Engqvist(Int. J Ref Metals & Hard

Mater 21 (2003) (55–61))

[85]Larsen-Basse ( J Effect of composition, J Metals

1983,November (35-42))

[86]Hwan-Cheol Kim , In-Jin Shon , J.E. Garay , Z.A. Munirb(Int. J Ref Metals & Hard Mater (2004) (257–264))

[87]Hwan-Cheol Kim, Dong-Ki Kim, Kee-Do Woo, In-Yong Ko, In-Jin Shon (Int J Ref Metals & Hard Materials 26 (2008)( 48–54))

[88] Seung I. Cha, Soon H. Hong (Materials Science and

Engineering A356 (2003)(381/389))

[89]Kuo-Ming Tsai, Chung-Yu Hsieh, Horng-Hwa Lu

(Ceramics International 36 (2010) 689–692)

[90]LIU Xiang- qing, LIN Tao, GUO Zhi- rneng, CUI Feng- e, LUO Ji (Materials Science & Engineering School, University of Science & Technology Beijing, Beijing 100083, China)

[91]B. Huang , L.D. Chen , S.Q. Bai ( Scripta Materialia 54 (2006)( 441–445))

[92]S.G. Huang, K. Vanmeensel, O. Van der Biest, J. Vleugels(Int. J Ref Metals & Hard Mater 26 (2008)( 41–47))

[93]Kuo-Ming Tsai (Int. J Ref Metals &Hard Mater 29 (2011) 188–201)

[94]M. Sherif El-Eskandarany (J Alloys and Compounds 296 (2000) 175–182)

[95]Hwan-Cheol Kim, Hyun-Kuk Park, In-Kyoon Jeong, In- Yong Ko, In-Jin Shon( Ceramics International 34 (2008) (1419–1423))

[96] Guy Anné, Stijn Put, Kim Vanmeensel, Dongtao Jiang, Jef Vleugels, Omer Van der Biest (J the European Ceramic Society 25 (2005) 55–63)

[97]EDUARD KIMMARI , IRINA HUSSAINOVA, ANTON SMIRNOVA, RAINER TRAKSMAA AND IRINA PREIS (ESTONIAN JOURNAL OF ENGINEERING, 2009, 15, 4, (275–282)

[98]H Engqvist , G. A. Botton , N. Axdn , S. Hogmark

(Int.l J Ref. Metals & Hard Mater (1998) (309-313))

[99]Olivier Malek , Bert Lauwers , Yeczain Perez , Patrick

De Baets , Jef Vleugels( J of the European Ceramic Society

29 (2009) (3371–3378))zro2

[100]B. Basu, T. Venkateswaran, D. Sarkar (Journal of the

European Ceramic Society 25 (2005) (1603–1610))

[101]H. Engqvist, N. Axen, S. Hogmark(Wear 232 1999 (157–162))

[102]Moskała, N. and Pyda,W., (J. Eur. Ceram. Soc., 2006,

26, (3845–3851))

[103]S. Luyckx *, N. Sacks , A. Love (Int. J Ref Metals & Hard Mater 25 (2007) 57–61))

105Heinrich Klaasen, Jakob K ubarsepp(Wear 261 (2006) (520–526))abrasive wear

IJSER © 2012 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 3, Issue 9, September-2012 18

ISSN 2229-5518

[104]V. CHABRETOU, C. H. ALLIBERT, J. M. MISSIAEN (J OF MATER SC. 38 (2003) (2581 – 2590)

[105]Yu.V. Milman , S. Luyckx , IT Northrop (Int. J Ref

Metals & Hard Materials 17 (1999)( 39–44))

IJSER © 2012 http://www.ijser.org