The research paper published by IJSER journal is about The optimum time of etching proved the Sensitivity of the CR-39 detector 1

ISSN 2229-5518

The optimum time of etching proved the

Sensitivity of the CR-39 detector

Najeba F. Salih Mohamad S. Jaafar

najebafarhad@yahoo.com msj@usm.my

Radiation and Medical Physics, School of Physics, Universiti Sains Malaysia, Pulau, 11800USM Penang, Malaysia.

Abstract:

The ideal detector used in this study is the CR-39 polymer (Italy). A series of chemical etching experiments have been carried out on CR -39 detectors, irradiated with alpha particle. A alpha particle crossing a CR -39 sheet, leaves a trail of broken polymer links along its path (restricted to a microscopic cylindrical region). Experimental data has been analyzed to find out important track etch parameters. Both bulk etch rate an d diameter of tracks are found to vary with time of etching and concentration of normality for NaOH, the average values for the m are 1.190 µm/h and 1.172 µm/h, and 12.36 µm and 14.81µm, respectively. The critical angle of etching and track registration efficiency have also been determined using experimental data. All parameters depend on properties of incident ion and etching conditi ons. Results describing the dependence of track etch parameters on etching conditions have been presented. These results are useful in the interpretation of track data. Keywords: Alpha tracks, CR-39NTDs, Ion tracks, Bulk etch rate, Critical angle, Etching efficiency.

-------------------![]() -------------------

-------------------

Track detectors were discovered by Young, Silk and Barner and they have been widely used in science and technology [1]. The detection technique based on using track detectors is presently called solid state nuclear track detection (SSNTD)[2]. One of the most commonly detector used is CR-39NTD, because of its good sensitivity, stability against various environmental factors, and high degree of optical clarity [3] . The bulk etch-rate (VB) is one of

the basic parameters required for the use of the

Fast heavy ions can produce latent tracks in many dielectric materials, after adequate treatment, such as chemical etching [ 5] .The operation of the solid state nuclear track detector (SSNTD) is based on the fact that a heavy charged particle will cause extensive ionization of the material when it passes through a medium. A recent review on SSNTDs has been given by Nikezic and Yu. If a piece of material containing the latent track is exposed to some chemically aggressive solution (such as NaOH

or KOH solution), the chemical reaction would be

SSNTDs. The value of VB is required to be known many parameters such as track etch-rate, track

more intensive in the latent track. Such a solution is called the etchant [1]. Through the

Surface after time t

efficiency and track diameters . Therefore, it is important to critically assess the methods of

measuring VB [4].

etching, the latent track becomes visible as a particle

‘‘track” which may be seen under an optical microscope. Ion-track growth in SSNTDs has been

IJSER © 2012 http://www.ijser.org

The research paper published by IJSER journal is about The optimum time of etching proved the Sensitivity of the CR-39 detector 2

ISSN 2229-5518

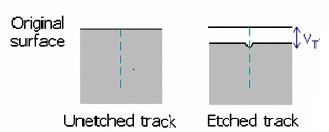

suggested to base on two parameters, VT and VB as shown in Fig (1).

Bulk etch rate is one of the crucial factors controlling the track development in SSNTDs[10].

![]()

Due t

Original surface

reaction between the etching

solution (etchant) and the detector material, some molecules of the detectors are removed. The final effect is the removal of the material from the detector surface and the thickness

of the detector becomes

Latent ion track

Fig.(1): Progressive effects of etching track detector[7]

VT is the track etch rate (the rate of etching along the particle trajectory) and VB is the bulk etch rate (the rate of etching of the undamaged detector surface) [8]. In other words, the bulk etch rate VB is the rate of removing of the undamaged surface of the detector. Track development is governed by the ratio V = VT/VB and track formation is not possible if V is smaller than or equal to 1 [1]. Research has been devoted to understanding the mechanisms of track growth in SSNTDs [9].

VB is influenced by many factors, such as the intrinsic characteristics of the plastic material, preparation method and the etching conditions in terms of temperature, concentration and type of etchant, etching duration, and stirring. VB has been measured by several experimental methods. Some

have been based on the measurement of a parameter

smaller and smaller [1]. There are many equation to determining the bulk etch rate (VB).

VB(h) = ∆h/2∆t -----(1)

where ∆h is the difference layer removed during the etching time ∆t.

VB = ∆m/2∆t A ρ ----(2)

where ![]() m is mass difference, A the etched surface area, ρ the density of the detector and ∆t is the etching time. However, this method is limited by the accuracy of mass measurements.

m is mass difference, A the etched surface area, ρ the density of the detector and ∆t is the etching time. However, this method is limited by the accuracy of mass measurements.

VB (m, h) = (∆m)h2/2∆t m2 ---(3) VB = D /2∆t ----(4)

The track etch rate (VT), is the rate of etching along the particle trajectory[11]. A track is formed

when VT > VB. and calculated by the relation

2 2 2 2

indirectly rated. In particular, direct methods for VB determination based on ‘thickness-measurement’ before and after etching by measuring the thickness decreased of the detector during etching and based on

‘mass-measurement’ is recording the mass of the detector before and after etching [4]. The indirect method is ‘diameter measurement’ by measurement of the track diameter resulting after etching for

specific time intervals [1].

VT =VB (4h +D )/ (4h - D ) ----(5)

VT depends on the etching temperature [12].conical holes (etch tracks), are produced on the surface at the position of particle impacts (two different etching rates (VB and VT)), as shown in Fig.(1)[13]

And all parameters determined by the following;

IJSER © 2012 http://www.ijser.org

The research paper published by IJSER journal is about The optimum time of etching proved the Sensitivity of the CR-39 detector 3

ISSN 2229-5518

V = VT/VB—(6)![]()

![]()

D = 2h![]() ---(7) V , the previous equation becomes

---(7) V , the previous equation becomes

D=2h =2VBt------(8)

Where D is track diameter, h2 is the thickness of the detector, m2 is mass of the detector after etching[1].

L = VT t – VBt ---(9)[14]. V= h/t----(10)

From Eqs. (9) and (10), V can be found as: V=1+L/h------(11)

One of the geometrical limitations for the revelation of the etched tracks in SSNTDs is called critical angle (θc) [15], determined by

Sin θc = VB/VT or

sin θc = 1/ (VT/VB) ,

CR-39NTD is a C12H18O7 polymer with a density of 1.31 g/cm3 [17]. The range of 5 MeV alpha particles in it is 28.77 µm. Gaillard et al [18] [19],

had a thickness of 700 µm cut into pieces with an area of (1.0 × 1.5) cm2[6] [20], before use. The detectors used in the present study is the ideal detector, produced by Intercase Europe SRL (43100

Parma, Italy). The Intercast CR-39 has a low background for small etching process for its use in radon dosimetry [21]. The efficiency of CR-39NTDs changes with time of storage therefore, the calibration process is required before using it. CR-

39NTD was calibrated and its efficiency was 79.5% .

The main characteristics of the detectors are listed in Table (1). The sensibility of CR-39 is physically able to register low energy alphas [21].

226

θc = sin-1(VB/VT) ---- (12)

Radium (

Ra; activity 5µCi) was used as an

Registration efficiency is very important parameter for any dosimeter and should be obtained before its use. The efficiency of each of the etchants was determined by using the values of VT and VB in a standard formula [16]. The partial sensitivities depend on the V function (V = VT/VB) as well as the thickness of the removed active layer during etching and on a critical angle, can be obtained by the following equations

ƒ = 1 − (VB/VT)

ƒ = 1- VB/VT = 1- 1/V

ƒ = 1- sin θc -----(13)[9]

alpha radiation source (for the irradiation of alpha

particle). For controlling the final alpha energies incident on the detector distances in normal air the distance between the radium source and the detector surface has been determined at Eα(0) is 5.49 MeV, the energy of alpha source and the source detector distances in air at normal temperature and pressure (NTP). The alpha particle range in the air is 4.08 cm. The range of alpha particle in air was changed by varying the source detector distance. Irradiation to the sources for 6 minutes irradiation at 2 hours interval was carried out [2].

The sodium hydroxide aqueous solution (NaOH) of 6.25 mol per liter was used as the etching solution. The etching was done in a bottle with a tight lid to prevent change in the concentration of the etching solution due to vaporization of water and absorption

of moisture. The etching process is performed in a

IJSER © 2012 http://www.ijser.org

The research paper published by IJSER journal is about The optimum time of etching proved the Sensitivity of the CR-39 detector 4

ISSN 2229-5518

thermostat bath which is electronically stabilized at

70 ºC. The chemical etching process involves 6.25M NaOH at 70![]() 5 ºC, distilled water and a water bath-

5 ºC, distilled water and a water bath-

‘‘gotech testing machines inc’’ modelGT-7039-

M,220V, 50 Hz. was used for heating the etching (6.25N NaOH ) water solution at 70 ±0.5 Cº for 8h [2].

The standard determination of VB is based on the measurement of the thickness of the detector after etching times and based on the determination of the mass of the detector after - before etching times. The thickness is measured with a digital micrometer of 1 ml accuracy in 10 positions on the detector foil and mass is weighted with an electric sensitive balance (Denver Instrument Company AA-200DS). The average bulk etch velocity was determined by using the above-mentioned values of VB.

The CR-39 detectors used in the present study are the ideal detectors (Intercast Europe srl (Italy) [21]. Each piece of CR-39 NTD for this study was irradiated at constant irradiation time [22] with alpha particles. Each detectors was been irradiated at 1 mSv/h with an 226Ra source [23] ( activity of 5µCi). After irradiation, these detectors were etched in an aqueous solution of NaOH by two methods. In the first method, many detectors were etched in different concentrations of N of NaOH maintained at 70 ºC for 8 hours of etching. In the second method, other detectors were etched in different time of etching with 6.25N of NaOH maintained at 70 ºC by a water bath ‘‘gotech testing machines inc’’ modelGT-7039- M, 220 V, 50 Hz”. The etchant was continuously stirred in order to assure its homogeneity, which

suggested the necessity of stirring to avoid the build

up of etching products at the surface of the samples affecting etching rate. After etching, The sample detector was then taken out from the etchant, washed for 20 min in running water in order to definitively stop the etching process and removing the NaOH present on the detectors surface the sample was then rinsed with distilled water. The detectors were dried in air completely and then used for analysis [24].

After the chemical etching, equations (2 ) and (5) were employed to calculate the bulk etch-rate and track etch rate, for the thickness measurement, mass- measurement and diameter-measurement methods, respectively. The thickness and weight of each detector was measured before and after etching. The thickness removed layers were measured ( micrometer was used to measure the alpha induced track thickness removed layer) and the mass of detector was weighted (using an electronic balance having an accuracy of 0.1 mg. For the scanning process, etched tracks were observed using an optical microscope fitted with a magnification of (40-100)X. The microscope image was viewed using a high quality monochrome charge coupled device (CCD) TV camera. The track densities ρ (number of tracks per unit area) are then found. Optimum values of time of etching and concentration of normality NaOH were determined. VB, VT and etching efficiency and the critical angle were calculated using equations in described in Ref.[1].

Result and discussion

The ideal detector used in this study is the CR-

39 polymer(Italy). When an alpha particle crossing a cast CR-39 sheet, it leaves a trail of broken polymer links along its path (restricted to a microscopic

cylindrical region). The CR-39 detectors irradiated

IJSER © 2012 http://www.ijser.org

The research paper published by IJSER journal is about The optimum time of etching proved the Sensitivity of the CR-39 detector 5

ISSN 2229-5518

with alpha particle from 226Ra source were etched in normality NaOH /1-propanol solutions. Various concentrations and time of etching were used to achieve the optimum processing conditions. For comparison purposes, CR-39 detectors were also etched in conventional aqueous solution of NaOH at different concentrations at 70 ºC. After weighting the mass of detector, VB, VT and ƒ were determined using the Eqs.(2), (5) and (13) respectively as follows.

a. In the bulk etch-rate using thickness-measurement method, the values of diameter (D) have been calculated according to Eq.(8). The average value of diameter (D) is (12.36 ± 0.012 ) µm when the irradiation time is fixed (5min) and the etching time is changeable at 6.25N NaOH with (70±0.5) ºC. When the optimum etching time is 8hours, the value of diameter at this value of optimum time of etching is (15.70 ±0.025) µm and the value of thickness at this time is (7.85 ±0.035) µm, as shown in Table (1). b. In the bulk etch-rate using mass-measurement method, the bulk etch-rate VB(M) is not a unique function of mass but depends up on either one or more the combination of other parameters namely, density of CR-39 is 1.31g/cm3 [19], thickness is (700

µm ) [21], area of CR-39 is 1.5cm x1cm as appear in

Eq.(2). The mass of the CR-39NTD was measured before and after etching. The average value of diameter is (11.98 ± 0.028 ) µm when the time irradiation is fixed 6min and the etching time is

8hours and the concentration of normality N of NaOH is changeable with (70±0.5) ºC. when the optimum etching time is 8hours, the values of diameter at the optimum time of etching is (15,68±0.025) µm and the thickness is (7.84±0.035)

µm, shown in Table (1).

The bulk etch-rate VB(M) was measured using the mass-measurement method in the first method, the average value of bulk etch-rate VB(M) is (1.190±0.091) µm/h when time of etching is changeable and the irradiation time is fixed at 6.25N NaOH with (70±0.5) ºC, but the value of bulk etch rate at the optimum time of etching is( 1.208±0.090)

µm/h. In the second method the average value of bulk etch-rate VB(M) is (1.172±0.092) µm/h when the etching time is fixed and the concentration of normality N of NaOH is changeable with (70±0.5)

ºC, and the value of bulk etch rate at the optimum time of etching is (1.224 ±0.090) µm/h. Both methods generate good values of VB. The value of VB in the first is (1.208±0.090) µm/h, however, is in agreement with 1.2 µm/h[19] for an etchant concentration of 6.25N at 70 ºC for 8 hours in Refs[21], [25]

Two other, important parameters critical angle of etching , and track etching efficiency, have been evaluated using Eqs.(12) and (13). For the optimum time of etching at concentration 6 N at 70 ºC for

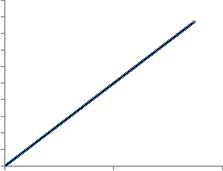

8hours. The critical angle of etching and track etching efficiency is 11.829 and %79.50, respectively. This is in agreement with Refs[21], [25]. The above suggested best etching conditions for CR-39 are useful for etching and for all samples. Fig(1) shows the relation for the removed layer with the time of etching, when the time of etching is increased the removed layer also increased (linearly).

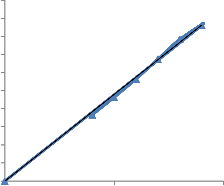

Fig(2) shows the relation of the diameter of track with the removed layer at 6.25N of NaOH concentration, when the removed layer increases, the diameter of track also increases (linearly).

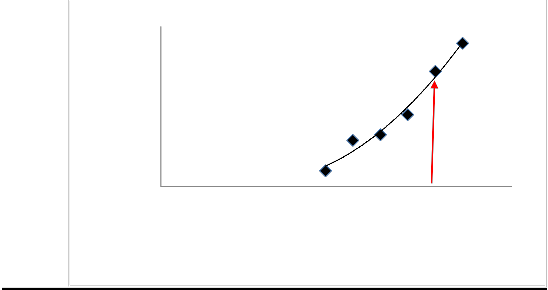

Fig(3) shows the change in bulk etch rate VB

with normality of an aqueous solution of NaOH. When the concentration of normality is increased, the

IJSER © 2012 http://www.ijser.org

The research paper published by IJSER journal is about The optimum time of etching proved the Sensitivity of the CR-39 detector 6

ISSN 2229-5518

VB also increased but not linearly, therefore. Thus the first method of changing the etching time with fixed normality is much better and accurate. This method gave a good efficiency of %79.50 and approximates the real value of the detector efficiency of %80 used in this work and in agreement with the value in Refs.[25],[21].

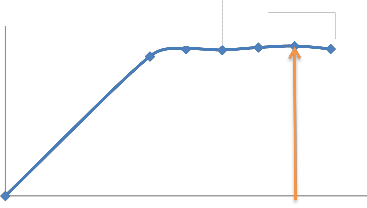

Fig(4) shows the relationship for the efficiency of track with the time of etching at 6.25N of NaOH

concentration and 70 ºC. When the time of etching

increases, the efficiency of track increases until reaching 8hours then decreased, therefore the optimum time etching is 8hours. The relationship between track diameters and etching time is displayed in Fig. 3.

The linear fitting of experimental data is described in

Tables (1) and (2).

x y =

x + y =

Etching time(h).

![]()

IJSER © 2012 http://www.ijser.org

Removed layer (µm).

![]()

The research paper published by IJSER journal is about The optimum time of etching proved the Sensitivity of the CR-39 detector 7

ISSN 2229-5518

x + - x y =

NormalitY (N).

6.25N NaOH at 70Co

79.50h

Etching time(h)

![]()

Table 1: Values of VB,V, h, D, ƒ and ϴ c for alpha particles of various etching in CR-39NTD.

Nu. Of detector | Thickness removed layer (µm) | Track diameter (µm) |

(m gm) | VB (µm/h) | Track etch rate ratio V = VT/VB | Track length-L (µm) | Critical angle (ϴ c) | Efficiency f % |

1 | 8.62 | 17.24 | 0.00425 | 1.199 | 4.526 | 38.043 | 12.764 | 77.93 |

2 | 7.85 | 15.70 | 0.00380 | 1.208 | 4.878 | 37.472 | 11.829 | 79.50 |

3 | 6.75 | 13.50 | 0.00330 | 1.197 | 4.697 | 30.975 | 12.364 | 78.71 |

4 | 5.65 | 11.31 | 0.00281 | 1.185 | 4.427 | 24.366 | 13.055 | 77.40 |

5 | 4.64 | 9.28 | 0.00232 | 1.178 | 4.271 | 19.265 | 13.540 | 76.59 |

6 | 3.67 | 7.35 | 0.00185 | 1.174 | 4.161 | 14.844 | 13.905 | 75.97 |

IJSER © 2012 http://www.ijser.org

The research paper published by IJSER journal is about The optimum time of etching proved the Sensitivity of the CR-39 detector 8

ISSN 2229-5518

Table 2: Values of VB,V, h, D, ƒ and ϴ c for alpha particles of various concentration in normality

NaOH in CR-39NTD.

Nu. Of detector | Thickness removed layer (µm) | Track diameter (µm) |

(m gm) | VB (µm/h) | Track etch rate ratio V = VT/VB | Track length-L (µm) | Critical angle (ϴ c) | Efficiency f % |

1 | 8.00 | 16.00 | 0.00425 | 1.259 | 4.411 | 34.352 | 13.000 | 77.37 |

2 | 7.84 | 15.68 | 0.00380 | 1.224 | 4.570 | 34.950 | 12.630 | 78.19 |

3 | 7.45 | 14.90 | 0.00330 | 1.170 | 4.456 | 32.340 | 12.960 | 77.56 |

4 | 7.24 | 14.48 | 0.00281 | 1.145 | 4.404 | 31.178 | 13.120 | 76.90 |

5 | 7.09 | 14,18 | 0.00232 | 1.138 | 4.087 | 28.104 | 14.160 | 75.50 |

6 | 6.83 | 13.66 | 0.00185 | 1.100 | 4.029 | 26.640 | 14.370 | 75.18 |

Acknowledgements

The authors thank the Universiti Sains .Malaysia USM of Penang /Malaysia for the academic support of this paper

References

[1]. D. Nikezica, D., Yu, K.N., Materials Science and Engineering R 46, 51– 123 (2004)

[2]. B.C. Milenkovi, D. Nikezi, N. Stevanovi, Radiation Measurements-Elsevier. 45 (2010) [3]. G. H. Ahn, J.K. Lee, Nuclear Engineering Hanyang University (2005)

[4]. F. Malik, et al. 2002Radiation Measurements- Pengamon 35 301 – 305 (2002)

[5]. J.P.Y. Ho, C.W.Y Yip, et al., Radiation Measurements- Pergamum 36 155 – 159 (2003) [6]. D. Nikezica, K.N. Yu, Nova Science Publishers, INC (2007)

[7]. S. Cecchini, Dipartimento diFisica, Italy (2005)

[8]. K. N.Yu, D. Nikezic, Nova Science Publishers, INC. (2009) [9]. N. F. Salih, (KAJ)Kurdistan Academicians Journal(2009)

[10]. K. P. Eappen, Y. S. Mayya, Indian J. Phys. 83 (6) 751-757 (2009) [11]. F. Gordon, Nuclear Reactions (2006)

[12]. S. Y. Y. Leung, et al., Applied Radiation and Isotopes 65, PP. 313- 317 (2007) [13]. S. M. Farid, Nuclear Physics(1993)

[14]. S. Cecchini, uclear Physics. Italy (2005)

[15]. K.N Yu, et al., Radiation Measurements 40, 380 – 383 b (2005) [16]. S. A. Durrani, R. K. Bull, Vol 111, Pergamon (1987)

[17]. E.U. Khana, et al., Radiation Measurements. 40 299 – 302. (2005) [18]. S. Gaillard, et al., 2007. 78, 013304 (2007)

[19]. S. Cecchinia, et al., 101, I-40129 Bologna, Italy(2000)

[20]. K. N. Yu, S. H. Cheng, Nuclear Instruments and Methods in Physics Research B (2009) [21]. J.K . SEK, et al., Bangladesh Journal, 2(1) 35.40 (2006)

[22]. K.F. Chan, et al., Nuclear Instruments and Methods in Physics Research B 263, 284–289(2007)

[23]. M. Dolleiser, S.R. H. Nezhad, Nuclear Instruments and Methods in Physics Research B 198, 98 107 (2002) [24]. F. Leonardi, et al., National Institute for Occupational Safety and Prevention Rome, Italy (2002)

[25]. K. N. Yu, et al., Radiation Protection Dosimetry. Vol. 111, No. 1, pp. 93–96 (2004)

IJSER © 2012 http://www.ijser.org