International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 225

ISSN 2229-5518

The Role of Steel Fiber of Influence on Properties of Self Compacting Concrete

Abbas S. AL-Ameeri

The purpose of presented research is investigating, the fresh properties of Steel Fiber SCC and the hardened properties were investi- gated. Fresh properties comprising flow ability, passing ability, and viscosity related segregation resistance. Hardened properties comprising compressive strength, splitting tensile strength, flexural strength, modulus of elasticity, and Ultrasonic pulse velocity .

The results indicated of the fresh properties of SCC with steel fiber , reduction in workability with increase of steel fiber content. Also the Steel fibers had effect on compressive & tensile strength , modulus of elasticity and ultrasonic pulse velocity of steel fiber self compacting concrete, there was an optimum content of steel fiber at which higher performance obtained at the both mentioned characteristics ,the con- tent was(0.75- 1)% . All fiber mixes demonstrated higher splitting tensile strength, and flexural strength relative to plain mix at all curing ag- es. The strengths increased as the fiber content increased. The fibers slightly decrease the U.P.V followed the same behavior as in com- pressive strength of SCC.

Index Terms— Steel fiber, Compressive strength, , tensile strength,flexural strength, modulus of elasticity , Ultrasonic pulse velocity,workability .

—————————— ——————————

he Self compacting concrete (SCC) is a concrete which has the ability to flow by its own weight and achieve good compaction without external vibration. In addition, SCC

has good resistance to segregation and bleeding because of its cohesive properties [1] . The raw material selection is an im- portant part of the mix design process for SCC, since it will sig- nificantly influence the stability as well as the cost of the mix, which are two key elements in the successful use of SCC.

There is no standard method for SCC mix design ,but many academic institutions, admixture ready-mix, precast and contracting companies have developed their own mix propor- tioning methods. Mix designs often use volume as a key param- eter because of the importance of the need to over fill the voids between the aggregate particles. Some methods try to fit availa- ble constituents to an optimized grading envelope (European Project Group, 2005) [2]. Mix designs of SCC must satisfy the criteria on filling ability, passing ability and segregation re- sistance. The most common method of mix design is the general method developed by the University of Tokyo and since then, many attempts have been made to modify this method to suit local conditions [3] .In general, the following rules should be followed to be successful in manufacturing SCC [4] ,with cer- tain methods are used ,there are many methods for design of mixes such as Rational methods [5],and EFNARC methods [2].

SCC is known to be brittle and can easily crack under low levels of tensile force. Inherently Plain, unreinforced con- crete is a brittle material, with a low tensile load and a low strain capacity. This behavior of brittleness can be overcome by using randomly oriented short discrete fibers. Fibers not only suppress the formation of cracks, but also abate their propaga-

tion and growth. Fibers have been added to `hardened state

————————————————

• Civil, Engineering/ University of Babylon, Babylon City, Iraq, (abb68abb21@yahoo.com)

Fiber reinforced concrete becomes an option whenever durabil- ity (limited crack widths) or safety considerations are design criteria. They improve the performance (strength and tough- ness) of brittle cement-based materials by bridging cracks, transmitting stress across a crack and counteracting the crack growth [6].The steel fiber is the most common fiber type in the building industry; plastic, glass and carbon fibers contribute to a smaller part to the market [7]. There are various types of steel fibers such as wave cut, end large steel fiber, deformed sheet and also hooked end steel fiber. In general, hooked end steel fibers are widely used in the fiber reinforced concrete because it has higher strengthening effect on the cement matrix as com- pared with other types of steel fibers [8] .Merging steel fibers with SCC to produce steel fiber reinforced self-compacting con- crete (SFSCC) is ,therefore, highly desirable and carries a lot of potential for the concrete industry. SFSCC is an innovative type of concrete, which combines the advantages and extends the possibilities of both SCC and steel fiber reinforced concrete, de- pendent on the type and the content of the fibers, the workabil- ity of SCC can be significantly affected[9].

In conventional concrete, Steel fibers have been applied to re- place bar reinforcement, to decrease the width of cracks, to in- crease tensile and flexural strength, and to improve the post- cracking behavior. Steel fiber reinforcement influences the way cracks develop in concrete and may impart improved crack growth resistance, increased surface roughness of individual cracks, and a greater likelihood for crack branching and multi- ple crack development. Due to this, steel fiber reinforcement may be used to significantly reduce the permeability of con- crete, thus improve the durability [10].

With regard to workability, the main parameters affecting it are

the fiber shape, the aspect ratio, the fiber length and the volume

of fibers per m³ of concrete. Generally the same parameters

which decrease the workability conversely increase the perfor- mance. Therefore it is important to find a compromise between

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 226

ISSN 2229-5518

WORKABILITY AND PERFORMANCE [11] . Steel Fibers need to be homogeneously distributed and clustering of fibers must be counteracted in order to optimize the performance of the fiber. The critical fiber content is surpassed when a stiff structure of the granular skeleton makes flow under concretes’ own weight impossible [12] [13].

In principle, the properties of the fresh self-compacting concretes should not be different from conventional concrete. Only one exception is regarding the consistency. SCC is gen- erally distinguished by their special fresh concrete proper- ties[14] .The workability of SCC is higher than the highest class of consistence described for conventional concrete and can be characterized by Filling ability, Passing ability and Seg- regation resistance ( European Project Group, 2005) [2].

Fibers affect hardened properties in different rates ,fibers

have little effect on compressive strength , a moderate on split- ting tensile strength but they are generally found to have much greater effect on the flexural strength of SFRC.

Steel fibers do not have the significant influence on the compressive behavior of concrete due to the small volume of

fibers in concrete mix[15].

(Maidl, 1995[16]; König & Kützing, 1999[17]; Sato et al.,

2000[18]) found that the addition of the steel fibers has hardly

any effect on the compressive strength just as on the tensile

strength. The ductility increases due to the addition of the fi-

bers.

In Iraq , almost searcher are used lime stone powder as a

powder in SCC mixes with cement , the lime stone powder is

inactive material [19],similar activated of aggregate but it has

finer than the fine aggregate .The used of this materials may

be change of the properties of SCC. From this point is carried

out this study to evaluate of performance of SCC with differ- ent steel fiber content at fresh and harden states .

For a newly developing material like self compacting concrete reinforced by steel fiber, studies on durability are of para- mount importance for instilling confidence among the engi-

neers and builders.

Ordinary Portland cement, which has specific gravity of 3.15 and the SO3 of 2.6, was used in this investigation. It is con- forming to IQS:5 -1984[ 20].

Rounded shape aggregate of size of 10 mm was used and it has the following properties: Specific gravity of 2.6 and the SO3 of 0.07%.

Natural sand conforming to zone III of IQS: 45 – 1984[21] was used and its properties are found as follows: Specific gravity 2.57 and the SO3 of 0.4%.

The drinking tap water has been used for both mixing and curing of concrete. A chemical admixture based on modified polycarboxylic ether, which is known commercially (Glenium

51) was used in producing SCC as a superplasticizer admix- ture. It was complied with (IQS No.1431-89)[22] and (ASTM C494-05)[23] type F .

This material was used to increase the amount of powder (ce- ment + filler). It has SO3 of 1.9 and its specific gravity was 2.8.

In this work, type of steel fiber having geometry of cylindrical with hooked ends was used. The characteristics of the steel fiber ; length, diameter ,tensile strength, specific gravity were 30mm , 0.5 mm,1100 MPa and 7000 kg/m3 respectively. It was complied with (ASTM A820M-11)[24].

The mix design method used in the present study was accord- ing to( EFNARC 2005) [2] . Table (1) shows the proportions of reference plain mixture.

TABLE 1

PROPORTIONS OF REFERENCE PLAIN MIXTURE

![]()

Cement kg/m3 | Sand kg/m3 | Gravel kg/m3 | LSP kg/m3 | SP L/m3 | Water L/m3 | w/c | w/p |

430 | 840 | 675 | 130 | 4.5 | 210 | 0.49 | 0.32 |

Fibers were added in quantities ranging from 0 to 1.5 % by volume of total mixture. Fibers were fed into mixer by hand to ensure that clumping and clustering effects were minimized. Fiber content in FRSCC mixtures are detailed in Table (2):

TABLE 2

FIBER CONTENT IN FRSCC MIXTURE

![]()

Mix Symbol Fiber Content by (Vol.%)

![]()

R Reference mix without fiber

![]()

ST1 0. 5 % steel hooked end hard-drawn wire fiber ST2 0.75 % steel hooked end hard-drawn wire fiber ST3 1.0 % steel hooked end hard-drawn wire fiber ST4 1.25 % steel hooked end hard-drawn wire fiber ST5 1.5 % steel hooked end hard-drawn wire fiber

The mixing process was performed in a drum laboratory mix- er of 0.05 m3 to mix concrete ingredients. For SCC mixes which require no compaction work, the mixes being poured into the tight steel molds until its fully filled without any compaction. All specimens were demoulded after 24 hours and initial curing in tap water was performed. The curing time was for three ages (7, 28 and 90) days, until the specimens are tested .

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 227

ISSN 2229-5518

The mix design should be tested by more than one method for the different workability parameters. Slump flow,T500, L-box and V- funnel test were used for assessment of fresh properties of SCC in this study.

The fresh properties of plain SCC and SCC reinforced by steel fiber were tested by the procedures of (European Guide- lines for self compacting concrete) [2] .

The mechanical properties studied are compressive strength, splitting tensile strength, flexural strength and static modulus of elasticity. Furthermore, the non-destructive test methods, Ultra-sonic pulse velocity test and Schmidt hammer test are used. The compressive strength test was performed in accordance with IQS:348-1992 [25] using 150 mm cube speci-

800

700

600

500

400

300

200

100

0

0.00 0.50 0.75 1.00 1.25 1.50

Steel Fiber Content by Vol. (%)

mens. The splitting tensile strength test was carried out ac-

cording to IQS:283-1995 [26] using Ø100 × 200 mm cylinder specimens. The test procedure given in IQS:291-1991 [27] was

used to determine the flexural strength using 100 × 100 × 400 mm prisms. The static modulus of elasticity was performed according to IQS:370-1993 [28] by using test cylinders of Ø150×300 mm . The Utrasonic Pulse Velocity test was con- ducted according to IQS:300-1993 [29] by using 150 mm cube

specimens.

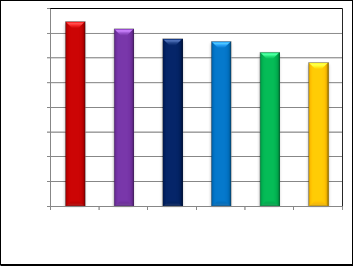

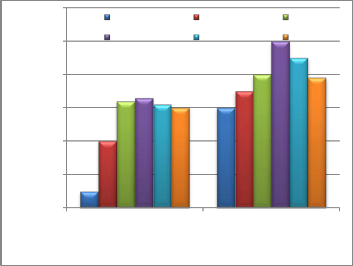

The flowing ability of fresh concrete is described by slump flow investigated with Abrams cone. Table (3) and Fig. (1) show the results of slump flow tests . The values of (D) represent the maximum spread (slump flow final diameter). All the mixtures had a slump flow diameter between (550-750) mm . Significant decrease in slump flow diameter has been observed with incorporating steel fibers in SCC mixes, adding steel fibers increases the resistance to flow and reduces the flowability due to increasing the interlocking and friction be- tween fibers and aggregate [30] . The decrease in slump flow was found to be increase with the increase in steel fiber con- tent. This is likely due to the effect of the higher number of steel fibers as well as higher internal resistance of the steel fibers in fresh concrete mixtures [31]

TABLE 3

![]()

RESULTS OF FRESH CONCRETE TESTS

Fig. (1) Effect of steel fiber content on Slump Flow Test of SCC

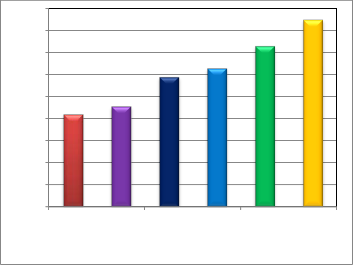

While the values of T500 mm represent the time required to the concrete flow to reach the 500mm diameter during the slump flow test was also measured and recorded as T500 (sec) (Slump Flow Time), which indicates the speed of flow and hence the viscosity of the self-compacting concrete. Table (3) and Fig. (2) show the results of T500mm . The values were ranged between (2.1-4.25) sec. According to the (European Project Group, 2005) [2], SCC can be classified as VS1 for T500

≤ 2 sec or VS2 for T500 > 2 sec.

Including steel fiber in SCC mixtures resulted in an in-

crease in T500 values. The increase percentages found to be

increase with the increase in fiber content. The increasing of

slump time due to increase of internal friction resultant from

higher number of steel fiber .

All results of slump flow and slump flow time were con-

formed EFNARC 2005 limitations.

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

Mix Steel Fiber

(% by Vol.)

D (mm)

TR500

R(Sec)

Blocking

Ratio (BR)

Tv

(sec)

0.0

0.00 0.50 0.75 1.00 1.25 1.50

![]()

SF1 0 750 2.1 0.97 6.6

SF2 0.5 720 2.28 0.94 7.0

SF3 0.75 680 2.95 0.90 7.7

SF4 1 670 3.14 0.85 8. 3

SF5 1.25 625 3.65 0.82 8.8

![]()

SF6 1.5 584 4.25 0.8 9.3

Steel Fiber Content by Vol. (%)

Fig. (2) Effect of steel fiber content on T 500 Test of SCC

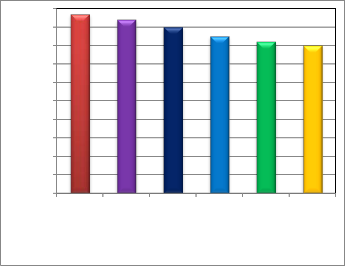

The L-Box with 2 bars was used in this study to assess the passing ability of the mixes. The Blocking Ratios results

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 228

ISSN 2229-5518

(BR=H2/H1) of the tests are summarized in Table (3) & plot- ted in Fig. (3). The results of the BR ranged between (0.8-0.97). The results show that the BR decreased with increasing steel fiber content . The higher the steel fiber content, the lower the BR was.

Introducing steel fibers had its impact on passing ability. The decreased the BR with increasing steel fiber content due to internal resistance of flow of concrete result of increasing of number of steel fiber [32] .

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

0.00 0.50 0.75 1.00 1.25 1.50

Steel Fiber Content by Vol. (%) Fig. (3) Effect of steel fiber content on Blocking Ratio Test of

SCC

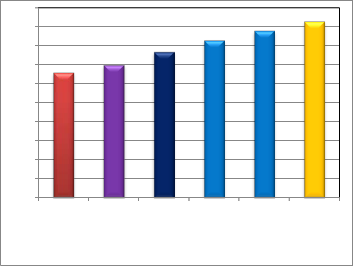

The V-funnel test is used to assess the viscosity and filling ability of self-compacting concrete [2] . Table (3) shows the results of V-funnel test. The Tv values ranged between(6.6-

9.3) sec. SCC is classified into two categories: VF1 (≤ 8 sec) and

VF2 (9-25) sec (European Project Group, 2005).

The results fall in VF1 and VF2 categories, referring to that

the mixes have moderate to relatively high viscosity , indicat-

ing reduced filling ability and at the same time ameliorated segregation resistance.

10

9

8

7

6

5

V-Funnel flow time increased by incorporating steel fibers in mixes as illustrated in Fig.(4). Similar behavior was observed in the T500 test. Besides,

the higher the steel fiber content, the more the flow-time in- creased. This can be ascribed to, the increasing in fiber content leads to increase the friction between the fibers and aggregates and the friction of the fibers with each other which could ex- tend the required time to empty the V-funnel [33].

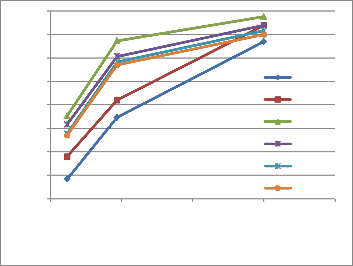

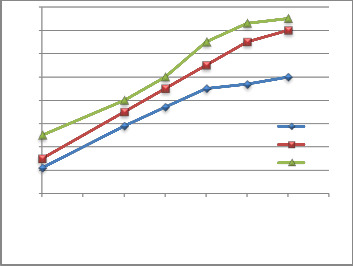

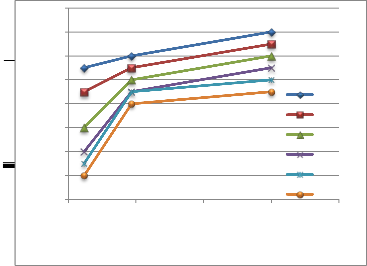

The compressive strength, is one of the most im- portant properties of hardened concrete .Table (4) and Fig.(5) show the average of the results of The compressive strength test at 7, 28and 90 days. The results indicate that all specimens exhibited a continuous increase in compressive strength with progress in age. This increase in compressive strength with age is due to the continuity of hydration process which forms a new hydration product within the concrete mass [34].Also the results indicate to compressive strength of the SCCs in- creases by steel fiber introduction, the compressive strength increases as the steel fiber volume increases up to 0.75% be- yond, the compressive strength decreases ,however, it still higher than the plain SCC as illustrated in Fig.(6) .The per- centage of changes (increase ) in compressive strength for all mixes with steel fiber content are represented in Table (4).

The increase in compressive strength may be associated with uniform dispersion of fine fibers throughout self- compacting concrete of high flowability, leading to consistent internal integrity. Also this improvement in the compressive strengths of the steel fiber reinforced SCC refer to the control of cracking and the mode of failure by means of post cracking ductility . However, steel fibers caused crack closing forces which led to increase the compressive strength. While, fiber addition caused the increase of entrapped air which decreased the compressive strength. Both effects in combination had the tendency to a little increase in compressive strength especially in SCC mixes reinforced with fibers higher than 0.75%. there- fore, the steel fibers could increase the compressive strength only if it does not change, to a certain limit, the air content [30]

TABLE 4

RESULTS OF COMPRESSIVE STRENGTH TEST OF SCC

![]()

Change in Compressive

4 Mix Compressive Strength(MPa)

![]()

3

strength with respect to refer- ence mix (SF1) %

2

1

0

0.00 0.50 0.75 1.00 1.25 1.50

Steel Fiber Content by Vol. (%)

Fig. (4) Effect of Steel Fiber Content on Flow Time at V Funnel

(TV) Test of SCC

7 days 28days 90days 7 days 28 days 90 days

![]()

SF1 27.5 35.4 45.1 - - -

SF2 30.4 37.6 47.2 10.55 6.21 4.66

SF3 35.6 45.2 48.3 29.45 27.68 7.10

SF4 34.5 43.2 47.2 25.45 22.03 4.66

SF5 33.3 42.5 46.5 21.09 20.06 3.10

![]()

SF6 33.1 42.1 46.0 20.36 18.93 2.00

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 229

ISSN 2229-5518

strength due to inclusion of fibers [7] [35].

49 TABLE 5

![]()

46 RESULTS OF SPITTING TENSILE STRENGTH TEST OF SCC

43

40 SF=0% SF=0.5%

Spitting Tensile Strength

Test

Mi (MPa)![]()

x

Change in Spitting Ten- sile strength with respect to reference mix (SF1) %

37 7

90 7

34 SF=0.75% SF=1%

31

SF=1.25

28

SF=1.5%

25

0 30 60 90 120 age (days)

Fig.(5) Development of compressive strength with age for different SF content in SCC

28 days 28 days 90 days

days days days

SF1 3.0 3.7 4.25 - - -

SF2 3.7 4.3 5 23.33 16.22 17.65

SF3 4.6 5.0 5.5 53.33 35.14 29.41

SF4 4.7 5.3 6.0 56.67 43.24 41.18

SF5 4.9 5.4 6.5 63.33 45.95 52.94![]()

SF6 5.0 5.5 6.5 66.67 48.65 52.94

7.0

49

46

43

40 7 days

37 28 days

34 90 days

31

28

25

0.00 0.25 0.50 0.75 1.00 1.25 1.50 1.75

Steel Fiber Content by Vol. (%)

6.5

6.0

5.5

5.0

4.5

4.0

3.5

3.0

2.5

SF=0% SF=0.5% SF=0.75% SF=1% SF=1.25

SF=1.5%

0 30 60 90 120

Age (days)

Fig.(7) Development of splitting tensile strength with age for different SF content in SCC

Fig.(6) Effect of SF content on compressive strength in SCC at age (7,28and 90) days

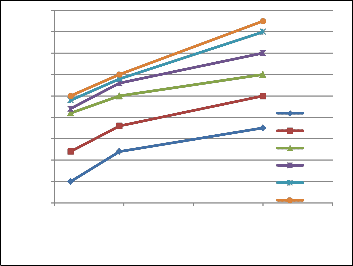

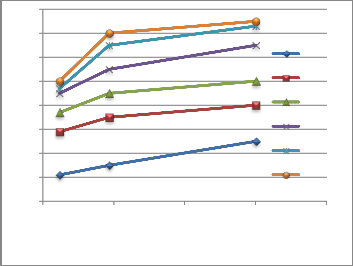

The results splitting tensile strength indicate that all specimens exhibited a continuous increase in splitting tensile strength with progress in age as summarized in Table (5) and Fig.(7).Also ,the results observed that splitting tensile strength of the SCCs increases with steel fiber content . The splitting tensile strength increases with increasing in steel fiber volume up to 1.5%.Also the percentage of increase in splitting tensile strength are listed in Table (5) and illustrated in Fig (8).

The strength increase due to inclusion of steel fibers is at- tributed to the mechanism of steel fibers in arresting crack progression. Where, the presence of fibers in concrete restrains

7.0

6.5

6.0

5.5

5.0

4.5

4.0

3.5

3.0

2.5

7 days

28 days

90 days

0.00 0.25 0.50 0.75 1.00 1.25 1.50 1.75

Steel Fiber Content by Vol. (%)

the development of internal microcracks and thus contributes to an increased tensile strength. Accordingly, the increase in fiber content leads to an increase in the tensile strength of con- crete. Moreover, the improved bonding of fiber-matrix that provided by the shape of the steel fiber , hooked ends, boost- ed pullout strength and thus, yielded high increment in

Fig.(8) Effect of SF content on splitting tensile strength in SCC

at age (7,28and 90) days

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 230

ISSN 2229-5518

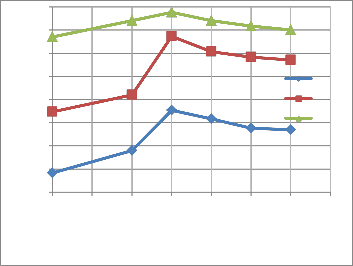

Similar to splitting tensile strengths of concrete, the results indicate that all specimens exhibited a continuous increase in flexural strength with progress in age as shown in Table (6) and Fig.(9) .The results indicate to effect of steel fiber on flex- ural tensile strength of the SCCs was very clearly ,and they showed the benefit of steel fibers to improve of flexural strength, This improvement in flexural strength increases with the increase in steel fiber volume up to 1.5%

The flexural strength indicated significant increase in strength due to the inclusion of steel fibers. The percentages of increase in flexural tensile strength for all mixes are summa- rized in Table (6) and illustrated in Fig.(10).

The flexural strength increases ,due to the superior perfor- mance in flexural strength for specimens with steel fibers aris- es from the improved fiber - matrix bond provided by using steel fiber with hooked ends [36] .

Also, the percent of increase in flexural strength was found to be increased with the increase in steel fiber content. This behavior is mainly attributed to the role of steel fibers in releasing fracture energy around crack tips which is required to extent crack growing by transferring it from one side to an- other side [37].

TABLE 6

RESULTS OF FLEXURAL TENSILE STRENGTH TEST OF SCC

![]()

Change in Flexural Tensile

When the tensile stress is transferred to fibers, the transfer can arrest the propagating macro-cracks and substantially im- prove. Crack control plays a crucial role in the performance of concrete in service. The loads may overstress hardened con- crete from cracking, leading from cracking to substantial fail- ure in concrete. Thus, incorporation of discrete fibers in vul- nerable concrete is useful and effective. The resulting fiber- reinforced concrete exhibits satisfactory resistance to crack formation and propagation[7].

12

11

10

9

8

7 7 days

6 28 days

90 days

5

4

0.00 0.25 0.50 0.75 1.00 1.25 1.50 1.75

Steel Fiber Content by Vol. (%) Fig.(10) Effect of SF content on Flexural tensile strength in

SCC at age (7,28and 90) days

Mix

Flexural Tensile Strength Test

(MPa)

strength with respect to reference mix (SF1) %

![]()

7 days 28 days 90 days 7 days 28 days 90 days

![]()

SF1 5.1 5.5 6.5 - - -

SF2 6.9 7.5 8 35.29 36.36 23.08

SF3 7.7 8.5 9 50.98 54.55 38.46

SF4 8.5 9.5 10.5 66.67 72.73 61.54

SF5 8.7 10.5 11.3 70.59 90.91 73.85

![]()

SF6 9 11 11.5 76.47 100.00 76.92

.

12

11

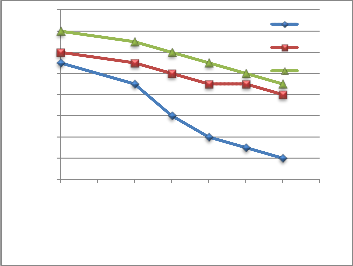

The static modulus of elasticity for all mixes is experimentally determined at ages 28 and 90 days, the results of this test are listed in Table (7). The results listed in Table (6) and plotted in Fig.(11)show steel fibers demonstrated similar impact on elastic modulus as on compressive strength. However, the increments due to incorporating steel fibers were insignificant, the percentages of change in elastic modulus for SCCs are listed in Table (7) and plotted in Fig.(12) Since, the main role provided by steel fiber starting after the concrete suffering plastic deformation , thus, steel fiber would not contribute much to elastic deformation stage

10 SF=0%

9 SF=0.5%

8 SF=0.75%

7 SF=1%

6 SF=1.25

5 SF=1.5%

[38] [39] .

4

0 30 60 90

Age (days) 120

Fig.(9) Development of Flexural tensile strength with age for different SF content in SCC

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 231

ISSN 2229-5518

TABLE 7

RESULTS OF MODULUS OF ELASTICITY TEST OF SCC

30

![]()

[35].

29

28

27

![]()

26

25

24

28 90

Age(days)

TABLE 8

RESULTS OF ULTRA-SONIC PULSE VELOCITY TEST OF SCC

Fig.(11) Development of Modulus of Elasticity with age for different SF content in SCC

![]()

4.8

4.6

30

4.4

29

28

27

26

28 days

25

90 days

24

4.2

4.0

3.8

3.6

3.4

3.2

SF=0% SF=0.5% SF=0.75% SF=1% SF=1.25

SF=1.5%

0 30 60 90 120

Age (days)

0.00 0.25 0.50 0.75 1.00 1.25 1.50 1.75

Steel Fiber Content by Vol. (%)

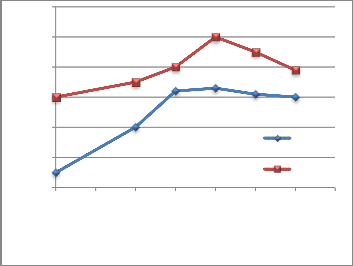

Fig.(13) Development of Ultra-sonic Pulse velocity with age for different SF content in SCC

Fig.(12) Effect of SF content on Modulus of Elasticity in SCC at age (7,28and 90) days

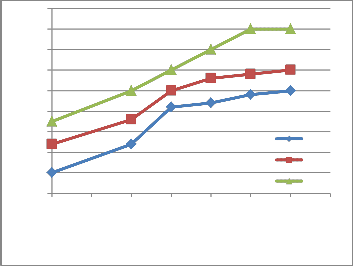

Ultrasonic pulse velocity increased with the increase in curing age of SCC mixes . The results of ultrasonic pulse veloc- ity for the various types of SCC mixes at (7, 28 and 90 days) are presented in Table (8) and Fig.(13). It can be seen that in- troducing steel fibers negatively affected the ultrasonic pulse velocity as shown in Table (8) and Fig.(14). This might be at- tributed to the increase of the amount of entrapped air voids due to incorporation of fibers into the mixes. besides, the fi- bers inside cube were randomly oriented, when the wave pass through the fibers the wave maybe deflected to other direc- tions rather than pass straight forward to the end of the cube

IJSER © 2 http://www.ijser.org

4.8

4.6

4.4

4.2

4.0

3.8

3.6

3.4

3.2

7 days

28 days

90 days

0.00 0.25 0.50 0.75 1.00 1.25 1.50 1.75

Steel Fiber Content by Vol. (%) Fig.(14) Effect of SF content on Ultra-sonic Pulse velocity in

SCC at age (7,28and 90) days

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 232

ISSN 2229-5518

4. CONCLUSIONS

1. Overall, slump flow diameter (flowability) and L-Box blocking ratios (passing ability) decrease with the increase in steel fiber content of the concrete mixtures with respect to plain mixtures. However, all mixes are satisfied to SCC requirements .

2. Slump flow time and V-funnel flow time increase with the increase in steel fiber content of the concrete mixtures with respect to plain mixtures.

3. Steel fibers increased in compressive strength and modu- lus of elasticity at early age, but at age 90 days, steel fibers had a marginal increments in compressive strength and modulus of elasticity compared to the increments in the other mechanical properties.

4. All steel fiber mixes demonstrated a higher splitting ten- sile strength and flexural strength relative to plain mixes at all curing ages. The tensile strength increased as the fi- ber content increased, however, the increments in flexural strength were higher than splitting tensile strength with more than 90% increments having been recorded.

5. Ultrasonic pulse velocity decreased with including steel fiber in SCC.

6. The highest steel fiber content 1.5 (% by Vol.) had, in gen-

eral, best effect on hardened properties but the worst on

fresh properties of SCC.

7. As well,(0.75, 1)% steel fiber content were sufficient for

achieving satisfying (optimum ) performance in fresh and

hardened properties of SCC.

The authors thanks Mahoumd R.H.and Ahmed S.M. for supported him to compelet this work .

[1] Okamura H., and Ouchi M., (2003), “Self-Compacting Concrete”, Journal of Advanced Concrete Technology, Vol.1, No. 1, pp.(5-15).

[2] European Project Group, (2005), “The European Guidelines for Self- Compacting Concrete: Specification, Production and Use”, pp.63.

[3] Hodws D.W., Sheinn A.M., Ng C.C., lim W.B., and Tam C.T., (2001), “Self-compaction concrete for Singapore”, 26th Conference on Our World in Concrete and Structures., 26-28 August, 2001, Singapore.

[4] Collepardi M., (2006), “Main ingredients and basic principles for SCC

production”, Department of Applied Physical Chemistry, Politecnico

of Milan, Italy.

[5] Okamura H., and Ozawa K., (1995), “Mix design for self-compacting

concrete”, Concrete Library of JSCE, No.25, pp.(107-120).

[6] Grunewald S., and Walraven J.C., (2009), “Transporting fibers as

reinforcement in self-compacting concrete”, HERON, Vol. 54, No.

2/3, pp.(101-126).

[7] Gencel O., Brostow W., Datashvili T., and Thedford M., (2011),

“Workability and mechanical performance of steel fiber-reinforced self-compacting concrete with fly ash”, Bartin University, Turkey

[8] Tadepalli P., Mo Y., Hsu T., and Vogel J., (2009), “Mechanical proper- ties of steel fiber reinforced concrete beams”, ASCE Structures Con- gress, pp.(1039-1048).

[9] Vikan H., (2007), “State of the art report on Concrete workability and fiber content”, SINTEF Building and Infrastructure ,COIN – Concrete Innovation Centre, Norway, pp.(1-38), www.sintef.no./coin

[10] ACI Committee 544.5R, (2010), “Report on the Physical Properties and Durability of Fiber-Reinforced Concrete“, American Concrete In- stitute.

[11] Pereira E.B., Barros J.A.O., Cunha V.M., and Santos S.P.,(2005),

“Compression and bending behavior of steel fiber reinforced self-

compacting concrete” , Portugal Civitest Company ,University of

Minho, Portugal

[12] Balaguru P., and Najm H., (2004), “High performance fiber- reinforced concrete mixture proportions with high fiber volume frac- tions”, ACI Materials Journal, Vol. 101, pp.(281-286).

[13] Grunewald S., (2004), “Performance based design of self compacting

fiber reinforced concrete”, Ph.D. thesis, Delft University of Technolo-

gy, Netherlands.

[14] Dehn F., Holschemacher K., and Weiβe D., (2000), “Self-compacting

concrete (SCC) time development of the material properties and the bond behavior”, LACER No. 5., pp.(115-124).

[15] Armelin H.S., and Helene P., (1995), “Physical and mechanical prop-

erties of steel fiber reinforced dry-mix shotcrete” ACI Materials Jour- nal, Vol.92, pp. (258-267).

[16] Maidl B.R., (1995), “Steel fiber reinforced concrete”, Ernst & Sohn, Berlin, ISBN: 3433012881.

[17] Konig, G., and Kutzing L., (1999), “Modelling the increase of ductility of HPC under compressive forces – a fracture mechanical approach”, Proceedings of the 3rd International RILEM Workshop on High Per- formance Fiber Reinforced Cementitious Composites(HPFRCC 3), Reinhardt H. W. and Naaman A. E., eds, RILEM Publications SARL, Mainz, Gernany, pp.(251-259).

[18] Sato Y.,Van Mier J.G., and Walraven J.C., (2000),“Mechanical charac-

teristics of multi-modal fiber reinforced cement based composites”, In Proceedings 5th International RILEM Symposium, Rossi p. and Chanvillard G., eds, RILEM Publications, Cachan Cedex, France, pp. (791-800).

[19] Mahmoud R.H., (2012), “Effect of sulfate on the properties on of self

compacting concrete reinforced by steel fiber ”, M.Sc. thesis ,College of Engineering, University of Babylon.

[20] Iraqi Specification, IQS No.5/1984, “Portland cement” Central Or-

ganization for Standardization &Quality Control COSQC, Baghdad,

2001.

[21] Iraqi Specification, IQS No.45/1984, “Aggregates from natural sources for concrete and construction” Central Organization for Standardization &Quality Control COSQC, Baghdad, 2001.

[22] Iraqi Specification, IQS No.1431/1989, “Admixture of concrete” Cen-

tral Organization for Standardization &Quality Control COSQC,

Baghdad, 2001.

[23] American Society for Testing and Materials, ASTM C 494-

2005,“Standard specification for chemical admixtures for concrete,” Annual Book of ASTM Standards, Vol. 04-02.

[24] American Society for Testing and Materials, ASTM A 820M-

2005,“Standard specification for steel fiber for fiber-reinforced con-

crete,” Annual Book of ASTM Standards, Vol. 04-02.

[25] Iraqi Specification, IQS No.348/1992, “Determination of compressive strength of concrete cubes,” Central Organization for Standardization

&Quality Control COSQC, Baghdad, 2001.

[26] Iraqi Specification, IQS No.283/1995, “Splitting tensile strength of

concrete” Central Organization for Standardization &Quality Control

COSQC, Baghdad, 2001.

[27] Iraqi Specification, IQS No.291/1991, “Modulus of rupture of con-

crete” Central Organization for Standardization &Quality Control

COSQC, Baghdad, 2001.

[28] Iraqi Specification, IQS No.370/1993, “Static modulus of elasticity of concrete” Central Organization for Standardization &Quality Control COSQC, Baghdad, 2001.

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 233

ISSN 2229-5518

[29] Iraqi Specification, IQS No.300/1993, “Pulse velocity through con- crete” Central Organization for Standardization &Quality Control COSQC, Baghdad, 2001.

[30] Al-Musawee H.A., ( 2011), “Effect of using fibers on some mechani- cal properties of self compacting concrete”, M.Sc. thesis ,college of Engineering, University of Babylon.

[31] Ahmed S.M., (2013), “The effect of elevated temperature on the

properties on of self compacting concrete reinforced by steel fiber ”,

M.Sc. thesis ,College of Engineering, University of Babylon.

[32] Grunewald S., and Walraven J.C., (2001), “Parameter-study on the

influence of steel fibers and coarse aggregate content on the fresh properties of self-compacting concrete”, Cement and Concrete Re- search, Vol. 31, pp.( 1793-1798).

[33] Neville, A.M.,( 2000), “Properties of concrete”, Longman Group

Ltd.,4th and Final Edition, pp. ( 329 – 397 ) , ( 674 – 687 ).

[34] Mon T. K., (2010),”Flexural behaviour of steel fiber reinforced con- crete slab”, B.Sc., College of civil Engineering, University of Technol- ogy, Malaysia.

[35] Banthia N., and Trottier J., (1994), “Concrete reinforced with de-

formed steel fibers, Part I: Bond-slip mechanisms”, ACI Materials

Journal, Vol. 91, No. 5, pp.(435-446).

[36] TengY.S.and Shah S.P.,(1986) ,“ Crack propagation in fiber reinforced

concrete ”,Journal of Structure Engineering ,Vol.112,1,pp(19-34).

[37] Alubaidi I.H., 2011, “Effect of curing conditions on the mechanical

properties of steel fiber reinforced self compacting concrete” Al- Qadisiya Journal For Engineering Sciences, Vol. 4, No.4, pp.(528-536).

[38] Aboud A.M., (2011), “Behavior of self compacting fibrous reinforced

concrete columns under transverse cyclic load”, M.Sc. thesis ,College of Engineering, University of Babylon

.

IJSER © 2013 http://www.ijser.org