water distillation and each unit 7 million Emperor gallons per day [6] .

International Journal of Scientific & Engineering Research, Volume 6, Issue 3, March-2015 - 1172 - ISSN 2229-5518

Mechanical Power Department , High Institute of Energy , Public Authority of Applied education and Training, Kuwait

Email: gmys2003@hotmail.com

The aim of the study is to identify major energy loss areas in AZZOR power station and develop a plan to reduce them using energy and exergy analysis as the tools .The energy supply to demand is reducing due to ageing of machinery .

Exergy analysis in power plants is a strong tool to evaluate cycle performance qualitatively , time dependent exergy loss that occurred in the major components of a 300 MW steam turbine unit of South-Zour power station.

Data used for analysis were both base parameters and measured values recorded in operation logbook for the period of 2010 to 2014. Component's exergy destruction increases as compared with its base value were recorded . Boiler exergy destruction percentage during this period were the evaporator had the highest value 57.36% with average 11.47% every year , the superheaters

16.8 % with average 3.36 % per year , Reheaters 11.8% with average 2.36%

per year , economizer 8.81% with average 1.76% , boiler feed water pumps

5.21% with average 1.04% per year . Renew boiler components with better designs , optimizing system, performance and elimination of conditions that degrade efficiency between maintenance outages were suggested for improving the performance of the boiler section . The results generally showed that exergy loss increased with increased operation time. It was noted that the suggested modification and overhaul of South-Zour power station boilers is an attractive solution to improve the plant economy and keep production cost competitive in a restructured Kuwait power system

Exergy ; South-Zour power station ; Components ; Boiler, exergy (keywords)

IJSER © 2015 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 6, Issue 3, March-2015 - 1173 - ISSN 2229-5518

1. Introduction

Exergy analysis in power plant is strong tool to evaluate cycle performance qualitatively time dependent exergy model was used to evaluate the exergy losses that occurred in the major components . Exergy can clearly identify efficiency improvements and possible reduction in resource energy losses .Therefore , in designing thermodynamic systems designers could focus on efficiency improvement at correct direction .

Exergy analysis provides clear distinction between energy losses to the environment and internal irreversibility of the process. Exergy is defined as the maximum theoretical useful work that can be obtained as a system interacts with an equilibrium state .

The objective of this study is to investigate the influence of aging on the exergy destruction in the main components of a 300MW boiler unit of South-Zour power station ,steam unit 2 used for this study was commissioned .The test result (actual conditions ) was compared with design condition to interpret deficiencies of individual components ,to evaluate aging effects on a steam power plant in Kuwait , a complete analysis based on thermodynamics rules were done in different loads . To accomplish this goal the real time data of unit was gathered using data acquisition system . The collected data was performed at 3 different loads . Comparing the results of exergy analysis of current situation with design ones represented degradation of unit components .

Many research studies have been carried to optimize process design from energy and exergy viewpoint , most of them included the effect of some design parameters on the exergy loss or second law efficiency in both steam cycles [1] and combined cycles [2] . Beside some studied off design conditions for , example, Rashad and El Maihey [3] have done an exergy analysis of a power plant in Egypt with capacity of 315MW.

Generally , design applications of exergy analysis aim to evaluate ,compare ,improve and optimize energy systems ,but almost a great number of papers discussing second law of thermodynamics just deal with

process optimization . As mentioned above , these efforts are useful in design

IJSER © 2015 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 6, Issue 3, March-2015 - 1174 - ISSN 2229-5518

phase of a unit , some studies presented an exergy analysis in an operating power station to find out the irreversibility and second law efficiency at aged units .As a power station particularly deals with high amount of energy , any changes of overall efficiency has high importance and should be carefully or degradation of components . In general aging is one of the most important reasons of efficiency reduction through the operation period , and many researchers focused on this . Despite many publications on the exergy analysis of power plant , most of them applied it to find optimum values for main cycle parameters .

Sina and Hamid [4] have done an exergy of power plant in Iran with nominal capacity of 320 MW , in this study an exergy analysis of an operating unit was performed to clear main sources of exergy destruction to find out aging influence on the plant performance ,out comes were compared with design results , this comparison cleared components which affected by aging and the amount of miss performance were specified too .

The data used for this study were base parameters for steam unit and measured values recorded in the station operation log book for the period of July 2010 to July 2014 . the data collection were the pressures , temperatures and mass flow rate at various points in the analysis of the data , mean values of daily parameters were compared using statistical methods .

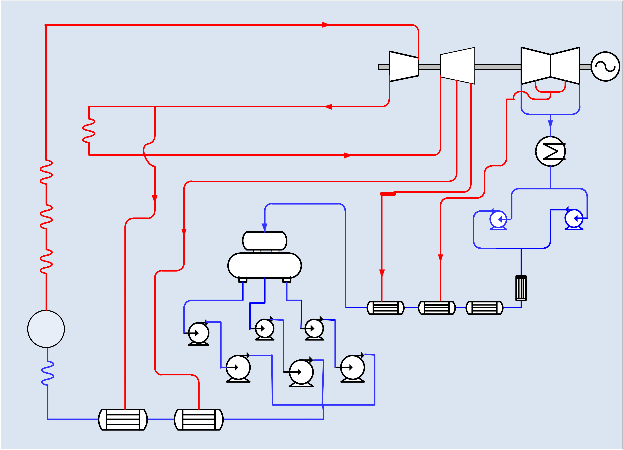

This was followed by monthly average and then the yearly average for the period of the research . Fig.1 shows schematic diagram of the power plant unit main which demonstrated all its relevant components , South-Zour power station unit in table (1) .

The average temperature ranges between 45 ° C in summer and 6° C Winter

[5]. In this study , the mean ambient temperature 46 ° C was used , and pressure

1.013 bar . in analyzing the unit , the cycle was assumed to operate at study state with no lose heat transfer from any component to its surroundings and negligible kinetic and potential energy effects ,such as boiler ,stop valves , fuel and oil pumps , forced draft fans were neglected in the analysis . Pressure drops

along pipelines were assumed to be negligible.

IJSER © 2015 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 6, Issue 3, March-2015 - 1175 - ISSN 2229-5518

South Zour station for electric power generation and water distillation, This station is located on the Arabian Gulf South Kuwait and the 8 units steam produce each unit of 300 MW and there are also 4 units of gas turbine for energy production and each unit producing 28 megawatts and the 16 units for

water distillation and each unit 7 million Emperor gallons per day [6] .

MS

H.P.T I.P.T

G

L.P.T

CR

RH

HR

3rd SH

Cond.

2nd SH

1st SH

Dea.

FWT

CP#1

CP#2

GSC

Drum

LPH#.3

LPH#2

LPH#1

Eco.

BP#1

BP#2

BP3

FWP#1

FWP#2

FWP#3

HPH#6

H.P.H#5

Where ,

Cond. : condenser

CP : condensate pump

BP : booster pumps ( 3 pumps)

FWP : boiler feed water pump ( 3 pumps ) L.P.H : low pressure heater , 1,2,&3

H.P.H : high pressure heater 5and 6

IJSER © 2015 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 6, Issue 3, March-2015 - 1176 - ISSN 2229-5518

ECO. : economizer

1st S.H. : primary super heater

2nd S.H. : secondary super heater

3rd S.H. : tertiary super heater

MS,CRH,HRH : main steam , cold reheat , hot reheat respectively. H.P.T,I.P.T, L.P.T. : high pressure turbine , intermediate pressure turbine &

low pressure turbine respectively .

DEA& FWT : deaerator and feed water tank .

Table 1. Design Condation at maximum Contenuous Rating

Component Maximum continuous Rating (MCR) | |

Steam Evaporation | : 975.6 t/h |

SH Outlet steam Pressure | : 145 bar |

SH Outlet steam | : 540°С |

Reheat Steam Flow | : 907.2 t/h |

RH Outlet steam Pressure | : 36 bar |

RH Outlet steam | : 540°С |

ECO. Inlet Feed Water | : 246 °С |

Ambient Air Temperature | : 46 °С |

Utilized Fuels | : Liquid Fuel (Heavy oil, Crude oil |

Burner type | : Oil/gas burner |

Draft System | :Forced draft |

Boiler Design pressure | : 173 bare |

Reheater Design pressure | : 50 bare |

IJSER © 2015 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 6, Issue 3, March-2015 - 1177 - ISSN 2229-5518

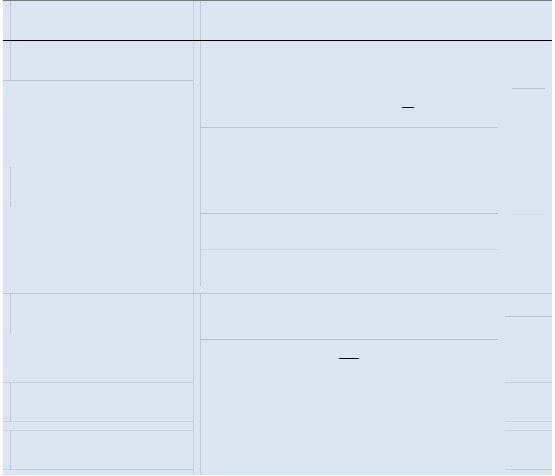

Table 2. Operating Condation of the 300MW Steam turbine unit

Operating parameters | ||||||||||||||

Average Temperature ( ºC) | Average pressure ( bar) | |||||||||||||

Components | Steam flow rate (kg/s) | 1988 | 2010 | 2011 | 2012 | 2013 | 2014 | 1988 | 2010 | 2011 | 2012 | 2013 | 2014 | |

Boiler feed water pump | inlet | 270 | 170 | 164 | 163 | 162 | 160 | 159 | 10 | 8.5 | 8 | 8 | 7.5 | 7.5 |

outlet | 270 | 175 | 166 | 165 | 163 | 162 | 160 | 170 | 166 | 165 | 162 | 160 | 158 | |

Economizer | inlet | 270 | 254 | 242 | 238 | 236 | 234 | 232 | 170 | 166 | 165 | 162 | 160 | 158 |

outlet | 270 | 270 | 264 | 260 | 254 | 252 | 250 | 169 | 165 | 164 | 161 | 159 | 157 | |

Evaporator | inlet | 270 | 279 | 264 | 260 | 255 | 252 | 250 | 170 | 166 | 165 | 162 | 160 | 158 |

outlet | 270 | 370 | 360 | 358 | 355 | 354 | 350 | 169 | 165 | 164 | 161 | 159 | 157 | |

Superheater | inlet | 270 | 370 | 360 | 358 | 355 | 352 | 350 | 155 | 150 | 147 | 145 | 142 | 140 |

outlet | 270 | 540 | 537 | 535 | 533 | 530 | 528 | 153 | 148 | 146 | 143 | 140 | 138 | |

Reheater | inlet | 270 | 370 | 360 | 358 | 255 | 252 | 250 | 155 | 150 | 147 | 145 | 142 | 140 |

outlet | 270 | 540 | 537 | 535 | 530 | 528 | 527 | 153 | 148 | 146 | 143 | 140 | 138 |

The mean daily temperature of the region around 40ºC all the year round , the maximum ambient temperature 48 ºC and minimum temperature is 32 ºC . In this study 44 ºC was used as the main ambient temperature and 101.3 kpa( 1.103 bar) as pressure .

The thermal power plant cycle was assumed to operate at steady state with no loss heat transfer from any component effects . Certain components such as boiler stop valves , crude and heavy oil pumps , forced draft fans and gas recirculation fans were neglected in the analysis , pressure drops along pipelines were assumed to be negligible .

IJSER © 2015 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 6, Issue 3, March-2015 - 1178 - ISSN 2229-5518

For control volume ,an exergy balance equation is expressed as:![]()

∑W • = ∑ (1 − T )Q• + ∑ Ψ• − ∑ Ψ•

− ∑ Ψ•

(1)

T in

out

dest

Table 3. Formula for the exergy destruction rate of the unit components

Components Exergy destruction rate

Boiler Feed water pump

•

dest . p

•

in. p

•

out . p

+ W •

(2)

Ψ• = C

[(T

− T ) − T ln(Tw )]

(3)

fwp

P.w w 0

o To

Wp = mw (Pout , w − Pin , w )

(4)

• •

Economizer

•

dest .eco.

•

in.eco.

•

out .eco.

(5)

Ψin ,eco. = mw [(hin − h ) − To (sin − so )]

(6)

• •

0

Ψout eco = mw [(hout − h ) − To (sout − so )]

• •

, . 0

(7)

Evaporator

•

dest .Evap.

•

in.Evap.

•

out .Evap..

(8)

•

in, Evap.

= Q• (1 −

T0

T flame

Super heater

•

dest .Evap.

•

in.Evap.

•

out .Evap..

(9)

Reheater

•

dest .Evap.

•

in.Evap.

•

out .Evap..

(10)

Where :

•

dest .

•

in.

•

out .

are destroyed rate , exergy rate inlet and exergy rate

outlet respectively .

W • is work rate (Power ) , P is pressure ,

Q • is heat add , To & T flame are

ambient temperature , flame temperature .

As mentioned above ,these set of data were collected from data acquisition system of power plant , some of these collections possibly are measured with poor accuracy . Using Mollier diagram and thermodynamic tables for steam and thermodynamic equations .

Table 3 summaries the equations used to compute the exergy destruction rate of the boiler main components

IJSER © 2015 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 6, Issue 3, March-2015 - 1179 - ISSN 2229-5518

Using the data obtained from operation log book and exergy relations and portion loss for each component were calculated . As expected boiler had the least efficiency ; as a result of high temperature difference between heat source (flame) and cold sources which are the main feed water and reheat steam .

After 26 years old of the power station( about 250,000 operating hours)were originally designed , the power plants were expected to run at bas load .The only thermal limit applied in the design was creep ; thermal fatigue resulting from frequent stops /starts was not anticipated . Steam power units of more than

250,000 operating hours are facing serious threats in view of their remaining lifetime . Even with proper operation and maintenance , the flow path section in the steam turbine plant will become fouled ,eroded ,corroded and covered with rust scale . The consequence is increased exergy destruction in their various components .

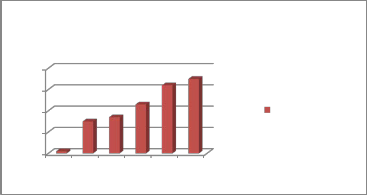

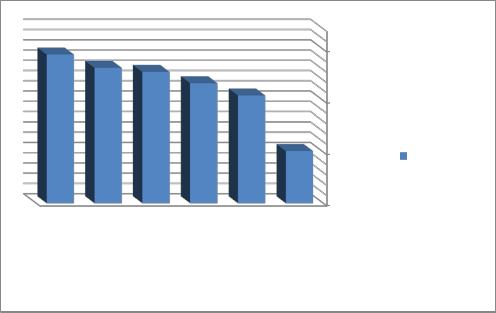

- Boiler feed water pump:

The base values of exergy destruction in boiler feed water pump are

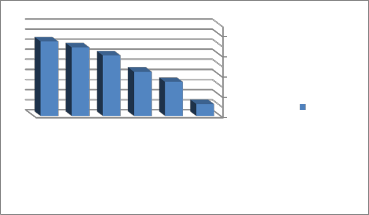

1.1MW , the increment from the base values for the period under review presented in figure 2 and figure 3.

4.7

4.2

3.7

3.2

2.7

2.2

1.7

1.2

0.7

9 July

1988

9 July

2010

12 July

2011

8 July

2012

9 July

2013

6 July

2014

Boiler

feed water pumps

Operation period

Figure 2 : Exergy destruction (MW) in boiler feed water pumps

Compared with the base values in 1988 , the boiler feed water pump has maximum of 4.5 MW , exergy destruction percentage during this period from 1988 to 2014 are 5.21% with average 1.04% per year , improvement

can be achieved by replacement of major portion or even the complete .

IJSER © 2015 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 6, Issue 3, March-2015 - 1180 - ISSN 2229-5518

Exergy Destroyed of Boiler feed water pumps( MW)

5.00

4.00

3.00

2.00

1.00

Exergy Destroyed (MW)

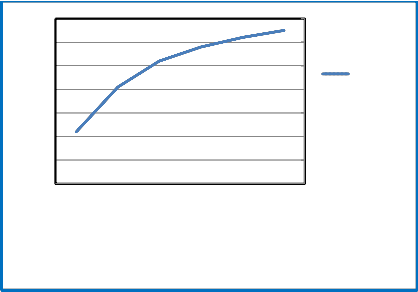

Figure 3 : Exergy destroyed rate of boiler feed water pump (MW)

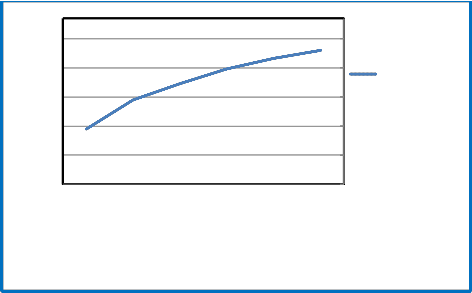

- Economizer :

In figure 3and figure 4 which illustrate the exergy destroyed rate in economizer in period 1988 to 2014 , the economizer has a minimum of 4.9 MW in 1988 and maximum of 7.6 MW in 2014 . economizer destruction percentage during this

period is 8.81% with average 1.76% per year .

8

7 Economizer

6

5

4

3

Operation period

Figure 4 : Exergy destruction (MW) in economiser

IJSER © 2015 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 6, Issue 3, March-2015 - 1181 - ISSN 2229-5518

8.00

7.00

6.00

5.00

4.00

3.00

exergy destroyed

2.00

1.00

0.00

Operation peroid

Figure 5 Exergy destruction rate (MW) of operation period in Economizer

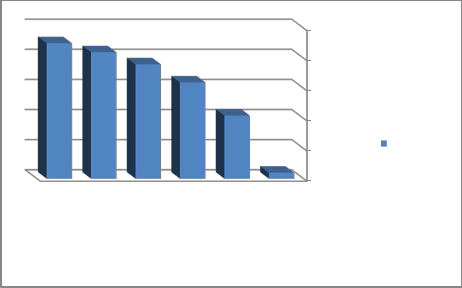

- Evaporator :

Evaporator exergy destruction rate is 40.1 MW in 1988 which increased to

49.9 MW in 2014 , : Exergy destruction rate percentage total is 57.36% with average 11.47% every year . in 2013 this percentage improved due to renew some parts of evaporator pipe lines .

51

49

47 Eveaporators

45

43

41

39

37

Operation period

Figure 6 Exergy destruction rate (MW) of operation period in Evaporator

IJSER © 2015 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 6, Issue 3, March-2015 - 1182 - ISSN 2229-5518

50

45

40 Eveaporators

35

Operation period

Figure 7: Exergy destruction rate (MW) of operation period in Evaporator

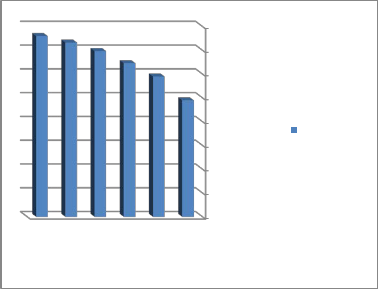

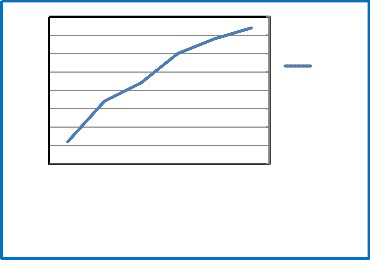

- Superheater :

The base value of exergy destruction in the superheater is 16.8 % with average

3.36 % per year . As can be observed the minimum increment of exergy destruction is 10.2 MW in 1988 , and a maximum 14.5 MW in 2014 , figure

8and 9 show the variation of exergy destruction with operation period in the

superheater .

15

14

13

Superheaters

12

11

10

9

8

Operation period

Figure 8 : Exergy destruction rate (MW) of operation period in Superheater

IJSER © 2015 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 6, Issue 3, March-2015 - 1183 - ISSN 2229-5518

15

14

13

12

Superheaters

11

10

Operation period

Figure 9 : Exergy destruction rate (MW) of operation period in Superheater

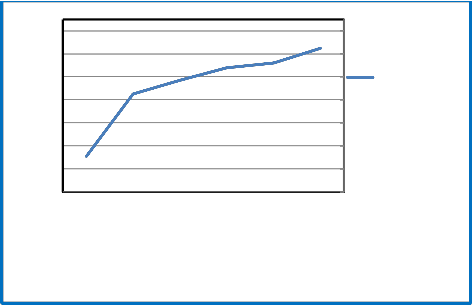

- Reheater :

Reheater exergy destruction rate is 7.1 MW in 1988 which increased to

10.2 MW in 2014 , Exergy destruction rate percentage total is 11.8% with average 2.36% per year

10.5

10

9.5

9

8.5

8

7.5

7

6.5

Reheaters

Operation period

Figure 10 : Exergy destruction rate (MW) of operation period in Reheater

IJSER © 2015 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 6, Issue 3, March-2015 - 1184 - ISSN 2229-5518

10.5

9.5

8.5

7.5

6.5

Reheaters

Operation period

Figure 11 : Exergy destruction rate (MW) of operation period in Reheater

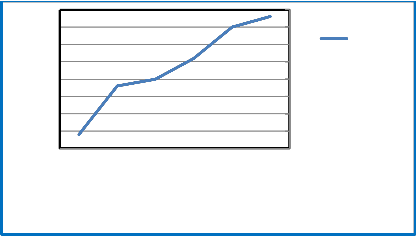

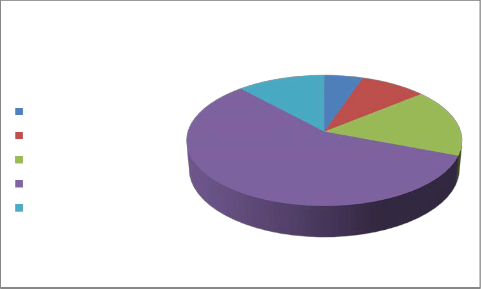

Exergy destruction rate percentage

Boiler feed water pumps

Economizer Superheaters Eveaporators Reheaters

Figure 12 : Exergy destruction rate percentage for boiler components

In this study , the effect of time on the analysis of exergy of 300MW boiler

has been applied to south ZOUR power station in Kuwait state. The

optimum operating values for 300 MW steam power plant within the stated design parameters has been 540 ºC . The analysis revealed that the highest increment increment in exergy destruction as a compared with its base value accrued in the boiler section . To evaluate aging effects ,the main components in a 300 MW steam unit were simulated using real time data in there different loads . the final point to emphasis is that boiler has the most growth in exergy loss due to aging . this feature has multiple effects as unit load decrease .

IJSER © 2015 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 6, Issue 3, March-2015 - 1185 - ISSN 2229-5518

[1] | Resat Selbas ,Hilmi Yazici "Thermoeconomic optimization of the steam power plant " ISSN2076-2909 (Online ) 2010 International Energy & Environment Foundation . |

[2] | J .C. Ofodu , D.P.S. Abam Exergy Analysis of Afam Thermal Power Plant ,Nigeran Society of Engineers (NSE) Tech. Trans , 37 (2002)14-28 |

[3] | A. Rashad and El Maihy " Energy and exergy analysis of a steam power in Egypt " 13 th International Conferrnace on Aerospace Science & Aviation Technolgy , Egypt 2009 |

[4] | Sina Salari and Hamid Abroshan "Aging Influence on Exergy Destruction in an Operating 320 MW Steam Power Plant " The 4 th International Meeting of Advances in Thermo fluids (IMAT 2011) |

[5] | Azoor power station ,Kuwait, operation log book . |

[6] | htt://www.mew.gov.kw/media/info.library/technical _speces _ reduced .pdf(enter 5th Agust2014) |

IJSER © 2015 http://www.ijser.org