The research paper published by IJSER journal is about Study of Mechanically Alloyed Magnetic Abrasives in Magnetic Abrasive Finishing 1

ISSN 2229-5518

Study of Mechanically Alloyed Magnetic

Abrasives in Magnetic Abrasive Finishing

M.G.Patil, Kamlesh Chandra, P.S.Misra

Abstract— Due to the development of manufacturing technology, final machining of precision parts having high level of surface finish has made the application of magnetic abrasive finishing (MAF) process, increasingly important. In MAF process, magnetic abrasives play the role of cutting tools. However, the magnetic abrasives are not easily available as these are produced by special techniques like sintering method, adhesive based, plasma based or gel based. This study presents the basic polishing characteristics of the magnetic abrasives produced by mechanical alloying process. After mechanical alloying process fine magnetic abrasives are obtained, in which the abrasive particles adhere to the base metal matrix without any bonding material. The magnetic particle used is iron powder and the abrasive is silica. The experiments performed on Stainless Steel 304 tubes examine the effects of different parameters like quantity of magnetic abrasives, amount of lubricant, speed of rotation of workpiece, magnetic flux density and machining time. The surface roughness measurements demonstrate the effect of the abrasive behaviour on the surface modification. The surface roughness was analysed in terms of percentage improvement in surface finish (PISF).

Keywords— Magnetic abrasive finishing, Mechanical alloying, Non-conventional machining, Surface finish, Surface roughness.

—————————— ——————————

1 INTRODUCTION

urface finish is a key factor in important functional properties, such as wear resistance and power losses due to friction, in many of the engineering components [1].

Various surface finishing techniques are used for final production of advanced materials with complicated shapes. Smoothly finished inner pipe surfaces are necessary to prevent the contamination of gas and liquid in high purity piping systems for critical applications, like aereospace components, atomic energy parts, medical instruments and semiconductor plants [2], [3]. Application of conventional finishing methods such as lapping and grinding are difficult for such components because of their shapes. The finishing technology for these components is very scarce in manufacturing fields [4]. Magnetic field assisted machining processes are gaining importance in finishing, cleaning, deburring and burnishing of metals and advanced engineering materials [5]. Magnetic abrasive finishing (MAF) is one of the non conventional machining processes in which cutting force is primarily controlled by the magnetic field and the magnetic abrasives play the role of cutting tools. This technique has been developed for finishing surfaces that are hard to reach by conventional techniques. The process can produce good surface quality of the order of few nanometers finish on flat as well as internal and external surfaces of cylindrical type workpieces [6], [7]. MAF has many advantages like self- sharpening, controllability, and the finishing tool requires nei- ther compensation nor dressing.

————————————————

In MAF, magnetic abrasives which play the role of cutting tools are very crucial in ensuring finishing of desired quality and accuracy. Magnetic abrasives can be of different types like mechanical mixture of abrasives and magnetic powder, sintered type, plasma based, cast materials and unbonded type. The mechanical mixture of abrasives and magnetic powder include abrasive coated magnetic powders. This method gives a wide variety of magnetic abrasives but abrasive layer may get worn off from the magnetic particle during the process, thereby affecting the finishing performance [8], [9]. Sintered magnetic abrasives have been used by most of the researchers due to its excellent finishing effects. The particles produced from this method are moulded in high temperature and high pressure within an inert gas atmosphere. The resulting compacts are then crushed mechanically and sieved to sort them into a specific particle size. The sintered magnetic abrasives are expensive because of the complicated manufacturing process and high cost equipment [10]. Also crushing of compacts resulted in irregular shape of magnetic abrasives and the improvement of finished surface quality was restricted due to non-uniform depth of cut. To overcome this difficulty spherical iron-based magnetic abrasive carrying Al2O3 particles on surface were produced by plasma spray method. The magnetic abrasives successfully machined the workpiece. However during machining, the problem of removal of Al2O3 particles from the magnetic abrasives was observed due to weak bonding strength between carried Al2O3 particles and iron particles in the composite powder [11]. The cast abrasives are made by

mgpatil.bms@gmail.com

Dr. Kamlesh Chandra (former Professor, MMED, IIT Roorkee)

is Director General of Roorkee college of Engineering, Roorkee,

India, E-mail: kc111fmt@gmail.com

Dr. P. S. Misra is former professor of Metallurgical and Materi-

als Engineering Department in IIT Roorkee, Roorkee, India,

E-mail: misraprabhu1@gmail.com)

[13]. The unbonded magnetic abrasive is a mixture of ferromagnetic particle and abrasives. The abrasive is not phys- ically bonded to the ferromagnetic material. In the magnetic field, the magnetic abrasives can move around freely within the constraints [14].

IJSER © 2012

http://www.ijser.org

The research paper published by IJSER journal is about Study of Mechanically Alloyed Magnetic Abrasives in Magnetic Abrasive Finishing 2

ISSN 2229-5518

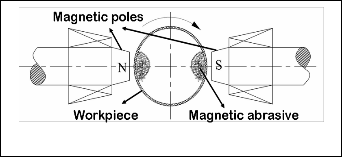

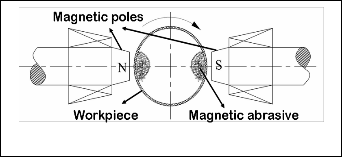

1.1 Principles of internal magnetic abrasive finishing

The process principle of internal MAF using a workpiece rotation system is shown in Fig. 1. When current is passed through the coils of the electromagnet, the poles of DC electromagnet generate the magnetic field. The magnetic field attracts the magnetic abrasives to the finishing area in the tube and presses the magnetic abrasive particles against the inner surface of the tube. The magnetic abrasives get conglomerated and form a flexible brush at the finishing area under the influence of magnetic force. When rotary motion is given to the workpiece, the material is removed from the inner surface of the tube by the magnetic abrasives due to the relative motion. The finishing force of the magnetic abrasive brush is controlled by the magnetic force acting on the magnetic abrasives which in turn is controlled by the current supplied to the electromagnet [15].

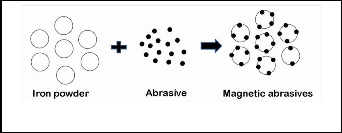

separation test to ascertain the strength of bonding. About 5 gm of alloyed magnetic abrasive powder was spread on a sheet of paper and a permanent magnet was moved at a distance. Perfect bonding was observed, as no powder was left on the paper.

Fig. 1. Schematic of internal MAF principle

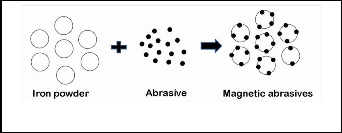

2 PREPARATION OF MAGNETIC ABRASIVES

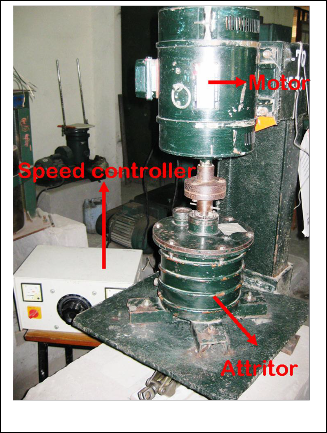

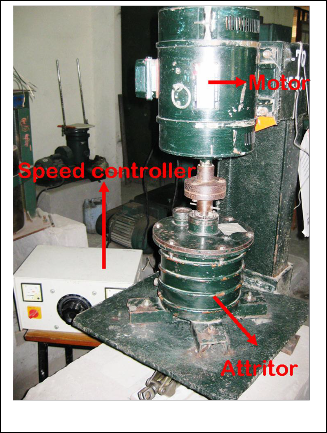

The magnetic abrasives in the present study are prepared by mechanical alloying process. Mechanical alloying is a solid state powder processing technique involving repeated welding, fracturing and rewelding of powder particles in a high energy ball mill or attritor at room temperature [16]. The manufacturing process by the mechanical alloying method suggested and the fundamental concept for producing magnetic abrasives is shown schematically in Fig. 2. It is the process in which fine grinding particles disperse into/on met- al particle by the repetitive pressure welding without using any binder.

Fig. 3. Photograph of attritor setup

Table 1: Parameters of Mechanical Alloying for preparing magnetic abrasives

Fig. 2. Schematic of mechanical alloying concept.

Fig. 3 shows the photograph of attritor setup used for mechanical alloying. Table 1 gives the parameters of mechanical alloying. The magnetic particle used in the particle production is the iron powder (80% by volume) of 120 μm and the abrasive is silica (20% by volume) of 120 μm.

The produced powder was subjected to magnetic

IJSER © 2012

http://www.ijser.org

The research paper published by IJSER journal is about Study of Mechanically Alloyed Magnetic Abrasives in Magnetic Abrasive Finishing 3

ISSN 2229-5518

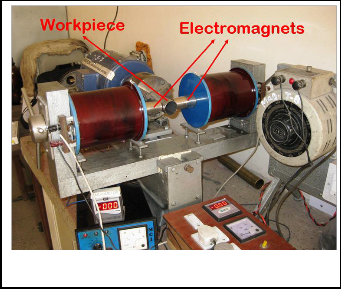

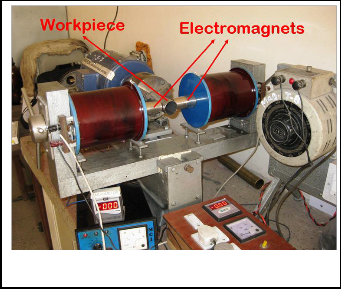

3 EXPERIMENTAL SETUP AND TEST CONDITIONS

Fig. 4 shows the photograph of the experimental setup used for internal MAF. Magnetic abrasives mixed with required amount of lubricant were packed inside the tube and magnetic field was applied by the electromagnets. The magnetic field was generated by two electromagnets, with their poles at 1800 apart. The field strength in the working zone was varied by supply current to the electromagnets. The working gap between the workpiece and poles of the elctromagnets can be varied based on the outer diameter of the workpiece. The setup was developed locally in the laboratory keeping in view different factors like magnetic flux density, workpiece rotation speed and working gap.

Table 2 lists the conditions used in MAF. The inner surface of SS304 tube was cleaned thoroughly with acetone before and after polishing. The finishing characteristics of magnetic abrasive powder was analysed by measuring the surface roughness (Ra) The Ra value was obtained using AMBIOS XP200 stylus profilometer. The stylus of the profilometer could not be inserted into the tube which created difficulty in measuring and tracking the changes in surface finish. Hence each experiment was run continuously for a certain period, and then the tube was cut open in the axial direction to evaluate the surface roughness. The Ra value was measured at five points along the length of tube and percentage improvement in surface finish (PISF) was calculated. PISF is defined as the ratio of (∆Ra x 100) and original surface finish value where ∆Ra is the difference between Ra values before and after MAF.

Fig. 4. Photograph of internal MAF setup

4 RESULTS AND DISCUSSIONS

During the tests, the parameters like pole to workpiece gap and percentage of silica in iron powder were kept constant. Some effective parameters like amount of magnetic abrasives, amount of lubricant, rotational speed of workpiece, magnetic flux density, and machining time have been varied and their effect on PISF has been studied.

Table 2: MAF experimental conditions

Workpiece | Commercially available SS304 tube of 38 mm outer diameter and 1.5 mm thickness. |

Magnetic abrasives | Silica based mechanically alloyed magnetic abrasives (20% silica and 80% iron by volume) |

Lubricant | Diesel |

Constant Parameters |

Pole- workpiece gap | 1 mm |

Variable Parameters |

Quantity of magnetic abrasives | 5 to 20 gm |

Magnetic flux density | 0.3 to 0.7 T |

Workpiece rotation speed | 400 to 1000 rpm |

Lubricant | 0 to 2 gm (0 wt. % to 20 wt. %) |

Machining time | 20 to 80 min |

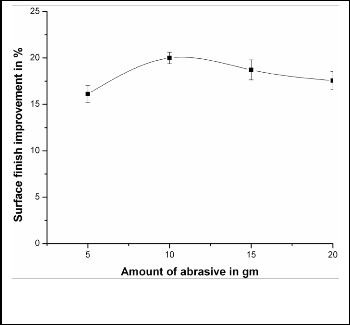

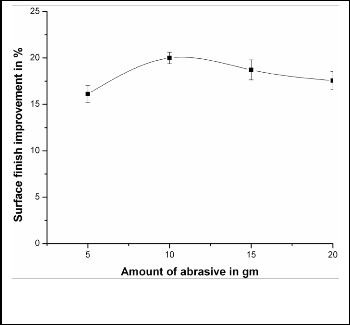

4.1 Effect of amount of magnetic abrasive powder

This test was conducted using 5 to 20 gm of abrasive powder mixed with 20 wt. % of lubricant. The rotating speed of work- piece was held at 800 rpm. The magnetic flux density was 0.5 T and the machining time was 60 minutes.

The result of PISF variation against the amount of magnetic abrasive powder is shown in Fig. 5. When amount of magnetic abrasives was increased from 5 to 10 gm, the PISF increased and then gradually decreased from 10 to 20 gm. When supplied excessively, the abrasives show an excessive tumbling and the rotation motion. Practically, the magnetic force is large in the inner wall surface of the tube, but smaller far from there. When the magnetic abrasives are supplied in excess, they fall off from the end portion of the magnetic abrasive brush. Hence, the amount of abrasives has a detrimental effect on the machining performance.

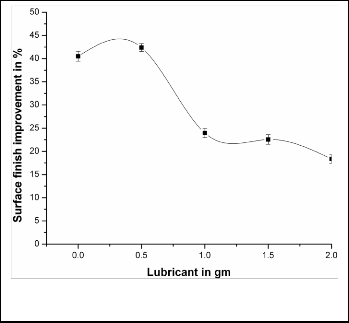

4.2 Effect of amount of lubricant

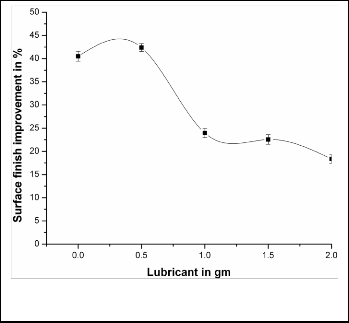

During the study abrasive quantity was 10 gm and amount of lubricant was varied from 0 to 2 gm (0 wt. % to 20 wt. %). The speed of workpiece rotation was 800 rpm. The magnetic flux density was 0.5 T and the machining time was 60 minutes.

Fig. 6 shows the results of varying lubricant amount. Initially the PISF increased marginally but when the amount of lubricant was increased from 0.5 to 2 gm, the PISF decreases. The oversupply of lubricant could either cause fluid lubrication between the abrasives and the workpiece or wash away the abrasives from the finishing area. The excessive usage of lubricant might have resulted in the slurrification of

IJSER © 2012

http://www.ijser.org

The research paper published by IJSER journal is about Study of Mechanically Alloyed Magnetic Abrasives in Magnetic Abrasive Finishing 4

ISSN 2229-5518

the magnetic abrasives in the lubricant. This reduces the number of cutting edges acting on the surface, thereby disturbing the finishing action.

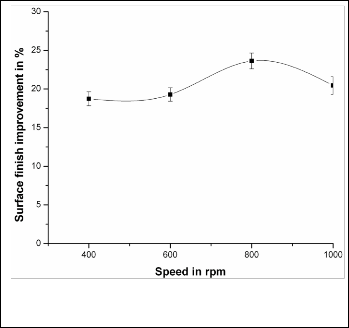

finishing surface.

Fig. 5. Amount of magnetic abrasives vs Percentage improvement in surface finish

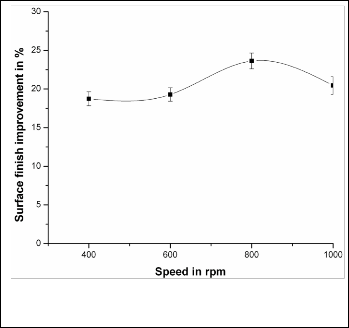

Fig. 7. Rotational speed of workpiece vs Percentage improvement in surface finish

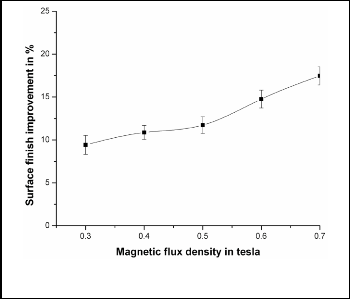

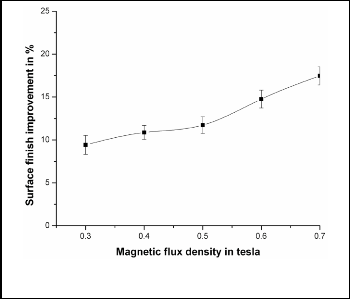

4.4 Effect of varying magnetic flux density

To study the effect of magnetic flux density, it was varied between 0.3 to 0.7 T. The other parameters: amount of abrasives was 10 gm, lubricant was 2 gm, speed of workpiece rotation was

800 rpm and machining time was 60 min. The results are shown in Fig. 8. When magnetic flux density increase, the PISF increases because of higher flux density in a specified gap. The increase in flux density leads to an increase in strength and area of contact of the magnetic abrasive brush. Higher density causes more force on abrasive tool and increases the finishing force. This increase can lead to finer surface roughness.

Fig. 6. Amount of lubricant vs Percentage improvement in surface finish

4.3 Effect of rotational speed of workpiece

The rotational speed of workpiece was varied between 400 to

1000 rpm during the test. The amount of magnetic abrasives

supplied was 10 gm mixed with 2 gm of lubricant. The

machining time was 60 min and the magnetic flux density of 0.5 T

was maintained. Fig. 7 depicts the results. It is evident that the

PISF increased initially with speed but then decreased as speed

goes beyond 800 rpm. This might be due to the fact that increase in circumferential speed has increased the centrifugal force acting

on the abrasive grains which leads to ejection of grains from the

Fig. 8. Magnetic flux density vs Percentage improvement in surface finish

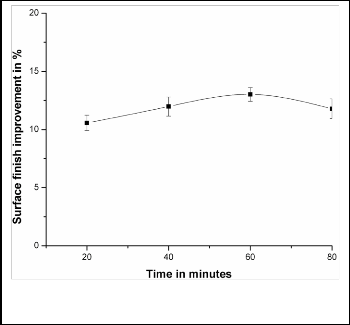

In these tests, the mixture of silica based magnetic abrasives and lubricant (10 gm and 2 gm) was used. The rotating speed of workpiece was kept at 800 rpm and the magnetic flux density

IJSER © 2012

http://www.ijser.org

The research paper published by IJSER journal is about Study of Mechanically Alloyed Magnetic Abrasives in Magnetic Abrasive Finishing 5

ISSN 2229-5518

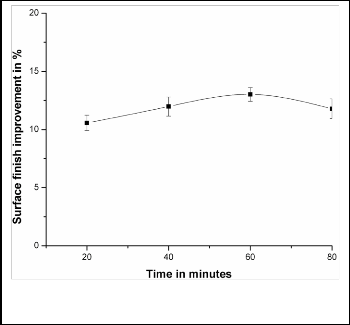

was 0.5 T. The experiments were repeated with four different time intervals of 20, 40, 60 and 80 min.

Fig. 9 shows the result of machining time effect on surface finish improvement. The fig. shows that increasing the time has positive effects on surface roughness until about 60 min. Further increase has no improvement effect.

In the beginning the cutting edges of abrasive grains are sharper. They remove more scratches and as a result PISF increases. With the passage of time, the amount of removed material from the workpiece increases. Also the density of abrasive particles decrease due to addition of removed material into abrasive powder. In fact, the number of effective abrasive grains decrease which may lead to a decrease in metal removal even though the process continues. The problem in long time finishing is that the removed material from the workpiece cannot be disposed from the environment. It gets mixed with abrasive particles and do not allow them to finish the surface efficiently. When finer surface is desired, one must stop the pro- cess and replenish the abrasive powder once in a while or there should be refining mechanism for abrasive powder.

Fig. 5. Machining time vs Percentage improvement in surface finish

4 CONCLUSIONS

A new method to produce magnetic abrasives by attritor ball milling was proposed which has resulted in simplification and economy of production.

The tests demonstrated the use of mechanically alloyed

silica based magnetic abrasives for internal finishing of

SS 304 tubes.

To obtain the best PISF, the suitable abrasive amount is about 10 gm with 0.5 gm of lubricant and a rotational speed of workpiece of 800 rpm.

With the mentioned conditions, the optimum finishing

time is about 60 min.

ACKNOWLEDGMENT

All the researchers, whose work is referred in the paper, are sincerely acknowledged.

REFERENCES

[1] P.Jayakumar, “Semi Magnetic Abrasive Machining”, 4th International Conference on Mechanical Engineering, December 26-28, 2001, Dhaka, Bangladesh, Section V, pp. 81-85. (Conference proceedings)

[2] Mehrdad Vahdati and Nader Vahdati, “Micromachining of

Aluminium Pipes using Magnetic Abrasive Finishing,” J. Vac. Sci. Technol. B 27(3), May/Jun 2009, pp. 1503-1505.

[3] Hitomi Yamaguchi, Takeo Shinmura and Atsushi Kobayashi,

“Development of an Internal Magnetic Abrasive Finishing Process for Nonferromagnetic Complex Shaped Tubes,” JSME International Journal, Series C, Vol.44. No. 1, 2001, pp. 275-281.

[4] Yan Wang and Dejin Hu, “Study on the Inner Surface Finishing of Tubing by Magnetic Abrasive Finishing,” International Journal of Machine Tools & Manufacture, 45, 2005, pp. 43-49.

[5] Dhirendra.K.Singh, V.K.Jain, V.Raghuram and R.Komanduri,

“Analysis of Surface Texture Generated by a Flexible Magnetic

Abrasive Brush,” Wear. 259, 2005, pp. 1254-1261.

[6] Shinmura.T, Takazava.K and Hatano.T, “Study on Magnetic Abrasive Process-Application to Plane Finishing,” Bulletin of Japan Society of Precision Engineering, Vol 19(4),1985, pp. 289-291.

[7] Yamaguchi.H and Shinmuira.T, “Study of the Surface Modification

Resulting from an Internal Magnetic Abrasive Finishing Process,”

Wear.225-229, 1999, pp. 246-255.

[8] Yin.S and Shinmura.T, “Study of Magnetic Field-Assisted Machining Process for Ferromagnetic Metallic materials,” Journal of Japan Soc.Abrasive Technology, 46(3), 2002, pp. 141-145.

[9] Bando.S, Tsukada.A and Kondo.Y, “A Study on Precision Internal Finishing for Alumina Ceramic Tubes,” Journal of Japan Soc. Abrasive Technology, 45(1), 2001, pp. 46-59.

[10] Singh.L, Khangura.S.S, and Mishra.P.S, “Performance of Abrasives used in Magnetically Assisted Finishing: a state of the art review,” Int. J. of Abrasive Technology, Vol.3, No.3, 2010, pp. 215-227.

[11] Hitomi Yamaguchi and Kotaro Hanada, “Development of Spherical Magnetic Abrasive made by Plasma Spray,” Journal of Manufacturing Science and Engineering, Vol.130, 2008, pp. 031107-1-031107-9.

[12] Gridasova.T.Ya, Zhornyak.A.F, Karpova.L.A, Karyuk.G.G, Oliker.V.E and Shlyuko.V.Ya, “Magnetoabrasive Materials from Melts,” Powder Metall. Met. Ceram, 19(7), 1980, pp. 505-507.

[13] Saito.T, Koike.K, Yamato.H, Kuwana.A, Suziki.A, Yamaguchi.H and Shinmura.T, “Development of Gas-Atomized Magnetic Tools,” Key Eng. Mater., 291-292, 2005, pp. 287-290.

[14] Geeng Wei Chang, Biing-Hwa Yan and Rong-Tzong Hsu, “Study on Cylindrical Magnetic Abrasive Finishing using Unbonded Magnetic Abrasives,” International Journal of Machine Tools & Manufacture, 42,

2002, pp. 575-583.

[15] J.D.Kim, “Polishing of Ultra-clean Inner Surfaces using Magnetic

Force,” International Journal of Advanced Manufacturing Technology, 21,

2003, pp. 91-97.

[16] C.Suryanarayana, “Mechanical Alloying and Milling,” Progress in Materi-

als Science, 46, 2001, pp. 1-184.

IJSER © 2012

http://www.ijser.org