International Journal of Scientific & Engineering Research, Volume 4, Issue 4, April-2013 738

ISSN 2229-5518

Studies on Dielectric Properties of Zinc Doped

Manganese Titanate (ZnxMn1-xTiO3, x=0.1, 0.3 &

0.5) Ceramics with Different Compositions

M. Maddaiah, A. GuruSampath Kumar, T. Subba Rao

Abstract— In this present study the Zinc Doped MnTiO3 ceramic powders were synthesized by solid state reaction route using metal oxides with heat treatments at and 1200oC for 12h. The characterizations of the ceramic samples were carried out by SEM, EDAX for structural studies and HIOKI 3532-50 LCR Hitester for dielectric measurements. It shows that the dielectric constant and Dielectric loss

were increased with temperature and decreased with frequency and observed the moderate increase of dielectric constant with t he addition of small amount of Zinc to the Manganese Titanate ceramics. The result were discussed in this study.

Index Terms— MnTiO3, Solid state reaction route, SEM, EDAX, Grain size, Dielectric Constant and Dielectric loss.

—————————— ——————————

1 INTRODUCTION

Microwave resonators, filters, oscillators or capacitors [1-3] play an important role in industrial or commercial electronic systems. The required materials to fabricate these components must exhibit a high dielectric constant, a low dissipation factor, a small temperature coefficient of the dielectric constant (ε’) [4,5], and that at high and hyper frequencies range. Most of the known dielectrics ceramics suitable for those applications require high sintering temperatures (1200–1500°C) to get well densified materials.

MnTiO3 ceramics [6] have the ilmenite structure, which is

an ordered derivative of the rhombohedral structure. MnTiO3

has much attractive material for the solar applications in visible spectrum because of strong absorption properties [7]. MnTiO3 and ZnTiO3 are the same crystal structure of

rhombohedral symmetry with a space group R 3 and both of them have close ionic radii for Zinc and Manganese. So it is possible to substitute the Zinc ion in to the Manganese to form the Zinc Doped MnTiO3 which might improve the dielectric properties of the ceramic sample were wide applications in the field of Microwave dielectric resonators, filters and gas sensor devices [8] etc.,

————————————————

Maddaiah. M is Presently pursuing Ph.D in Physics, Materials Research lab,Dept. of Physics, Sri Krishna devaraya University, Anantapur, Andhra Pradesh, India-515 003, E-mail:maddaiahphy@gmail.com

GuruSampath Kumar.A is presently working as a JRF in the Materials

Research lab,Dept. of Physics, Sri Krishna devaraya University, Anantapur, Andhra Pradesh, India-515 003,

E-mail:sampathkumar.physics@gmail.com

2 EXPERIMENTAL DETAILS

2.1 Materials

Titanium dioxide (TiO2) powder (P-25), Zinc Oxide (ZnO) and Manganese Corbate (MnCO3) were purchased from Aldrich Chemical (USA) with purities above 99.9%. Poly Vinyl Alcohol (PVA) as binder to prepare the pellets.

2.2 Preparation of Zinc Doped MnTiO3 Samples

Ceramic samples were prepared by the conventional Solid State Reaction Route [9] from oxide powders with purities above 99.9%. The starting materials were mixed in ethanol by Ball Milling for 12h with Zirconia balls in polyethylene jars and dried at 150oC. The mixed powders were calcined at

1150oC for 24h. The obtained grained powders were mixed

with 2.5 wt% of Polyvinyl Alcohol (PVA) solution as binder and then pressed into discs 10mm diameter and thickness of

2mm under hydrostatic pressure about 10Kg/cm2. The resultant pellets were sintered at 1200oC for 4h.

2.3 Characterization Techniques

The surface morphology [10-12] was examined by scanning electron microscopy (JEOL J. SM-35, Japan). Differential scanning calorimetry measurements were carried out in HT- DSC (SDT Q 600 (TA Instruments) equipment in order to investigate the phase formation in Zinc doped MnTiO3. The porosity were measure by the Archimedes techniques [13] using water immersion. The dielectric constant, loss tangent, ac conductivity were measured using HIOKI 3532-50 LCR HiTester (imported from Japan) with variation of temperature and frequency (upto 1MHz).

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 4, April-2013 739

ISSN 2229-5518

3 RESULT AND DISCUSSION

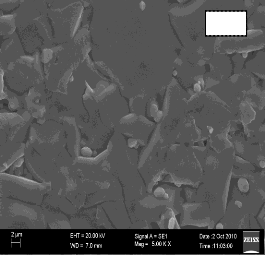

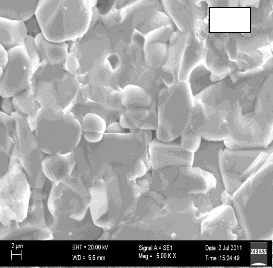

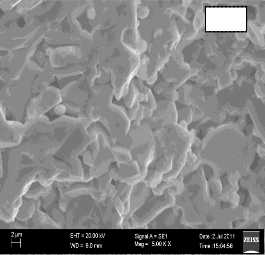

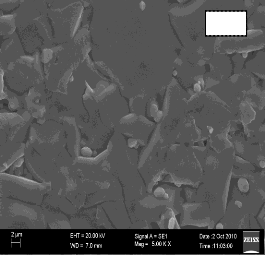

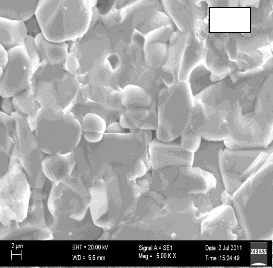

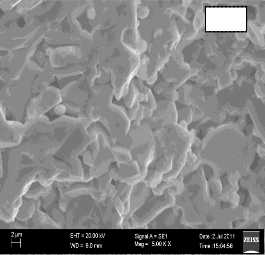

3.1 SEM & EDAX

The following fig.1 depicts the scanning electron micrographs of Zinc doped Manganese Titanate at different Zinc compositions with sintering temperature of 1200oC. The grain size is more in the composition of Zinc at x=0.5 because of the atomic radii of Zinc and Manganese is almost similar nature. The average grain size is in the order of 1-2 μm, which was slightly increased with increase of composition zinc. The density of the compound were increased with the increase of zinc composition and further (i.e., x>0.5) we are under study. The porosity of the samples was studied with the help of Scanning morphology and we found that the lower porosity because of the density was higher at higher composition. As the zinc compositions were increased into the perovskite structure lattice promotes the grain growth.

(a)

(c)

Fig 1. Shows the Scanning Electron Micrographs of ZnxMn1-XTiO3 at (a)

x=0.1, (b) x= 0.3 & (c) x= 0.5

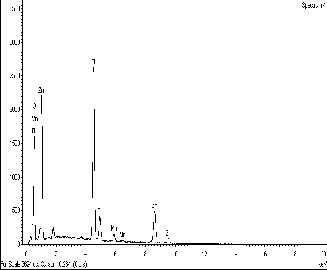

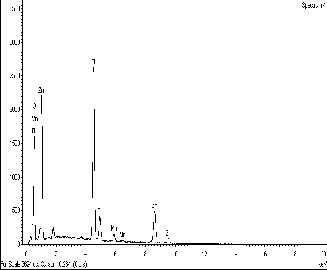

The EDAX analysis at x=0.1 for ZnxMn1-xTiO3 was depicted in the following fig. 2. From the EDA studies, we found that the elemental composition of the each element in the sample and the samples were well stochiometric which were shown in table 1. At the remaining compositions of zinc were observed with similar results but we go for high composition of zinc the Titanium ions will be dominated.

(b)

Fig.2. Shows the EDAX Data Analysis for ZnxMn1-X TiO3 at x=0.1

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 4, April-2013 740

ISSN 2229-5518

Table 1. Shows the Chemical composition of the sample at x=0.1

60

Element Weight% Atomic%

50

O K 46.22 74.56

Ti K 28.26 15.23 40

Mn K 1.94 0.91

30

Zn K 23.58 9.31

20

Totals 100.00

1KHz

10KHz

100KHz

1MHz

10

3.2 Dielectric Measurements

For dielectric measurements the powder form of the sample is grained for 12h and taken 1 gram of the sample then add small amount of PVA as a binder and prepare the pellet by pellet making machine with diameter 1.2cm and thickness

2mm with the application of hydraulic pressure of 10 Tons. These pellets were sintered at 1200oC for 4h. Then these pellets were used for the dielectric measurements with the help of HIOKI 3532-50 LCR Hitester (Imported from Japan) at different frequencies and different temperatures.

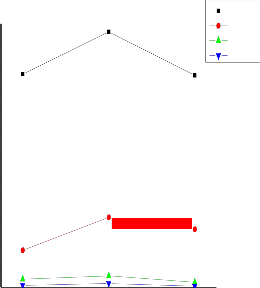

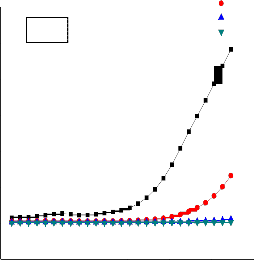

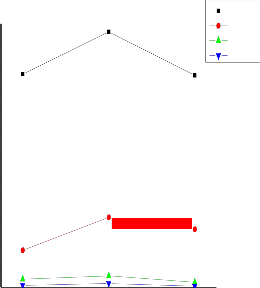

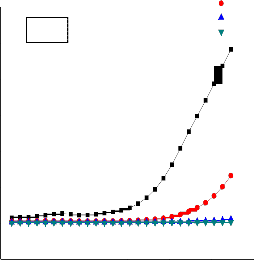

From fig. 3, the dielectric constant variation with frequency and we found that the dielectric constant is maximum at composition x=0.3 and the decreased at all frequencies because which might be the smaller ionic polarizability of manganese than that of zinc.

0 0.1 0.2 0.3 0.4 0.5

composition of Zinc

Fig.3. Shows the Dielectric Constant Variation with

Composition of Zinc in MnTiO3

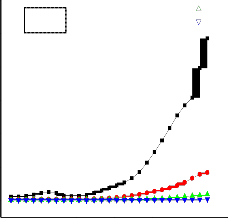

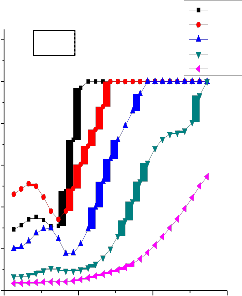

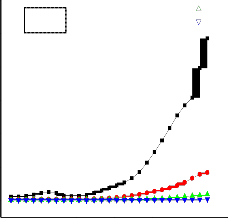

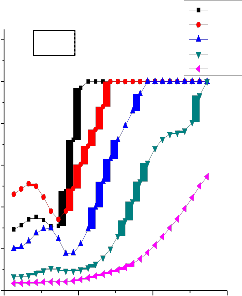

The dielectric constant variation with temperature of ZnxMn1-xTiO3(x=0.1, 0.3 & 0.5) at different frequencies are shown in fig.4. From fig.4(a), the dielectric constant variation with temperature at different frequencies with the composition of zinc x=0.1 and we observed that the dielectric constant were increased with temperature and decreased with frequency because of the off-center ion displacement of the Zn2+ at A site in the manganese titanate ceramics.

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 4, April-2013 741

ISSN 2229-5518

60

(a)

30

(c)

40

20

20

10

0

300 400 500 600

Temperature(K) 0

300 400 500 600

Temperature(K)

60

(b)

40

20

Fig.4. Shows the Variation of Dielectric Constant vs. Temperature of

ZnxMn1-XTiO3 at (a) x=0.1, (b) x=0.3 & (c) x=0.5

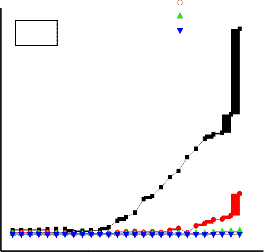

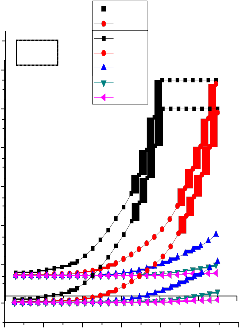

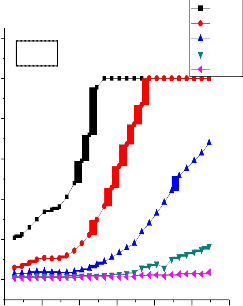

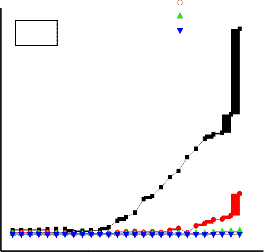

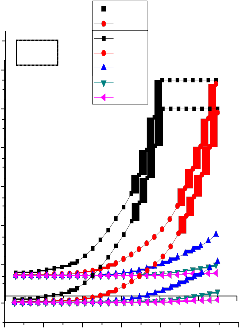

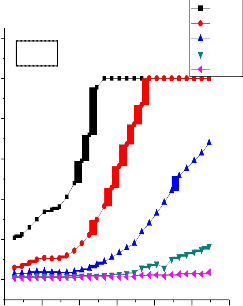

The dielectric losses of the material were studied with respect to temperature at different frequencies which are shown in fig.5. Fig.5.a shows that a small hump at 370Kwere observed and then further increased with respect to temperature at all frequencies. Similar results were observed when x=0.3 and x=0.5 also, which were shown in fig.5.b.and

5.c. The dielectric loss tangent (δ) was relatively high because

of the magneto resistive effect of manganese content.

0

300 400 500 600

Temperature(K)

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 4, April-2013 742

ISSN 2229-5518

12 (a)

10

8

100Hz

1KHz

10KHz

100KHz

1MHz

12

(c)

12

10

10

8

100Hz

1KHz

100Hz

1KHz

10KHz

100KHz

1MHz

8

6

6

4

2

0

300 400 500 600

Temperature (K)

6

4

4

2

2

0

0 300 350 400 450 500 550 600

Temperature (K)

300 350 400 450 500 550 600

Temperature (K)

12

(b)

10

8

6

4

2

0

100Hz

1KHz

10KHz

100KHz

1MHz

Fig.5. Shows the Variation of Dielectric Loss Vs. Temperature of ZnxMn1- XTiO3 (a) x=0.1, (b) x= 0.3 & (c) x=0.5

4 CONCLUSIONS

The dielectric characteristics and microstructure were investigated as function of Zn content. The dielectric constant was affected because of the Zinc composition in the manganese titanate ceramic sample. Therefore the dielectric constant were increased with temperature and decreased with frequency. When the composition x=0.3 the maximum dielectric constant were observed and then decreased slightly as the composition were increased are reported. The dielectric loss were increased with temperature and decreased with frequency. From SEM morphology we found that, the grain growth were increased when the composition were increased. Finally with the substitution of Zinc ion into the Manganese ion, it enhances the dielectric properties of the ceramic samples.

300 350 400 450 500 550 600

Temparature (K)

ACKNOWLEDGMENT

The author wish to thank Prof. Sreedhar Reddy, SVU, Tirupati for SEM and EDAX and Prof. GunaSekhar, IISC, Bangalore for their valuable suggestions.

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 4, April-2013 743

ISSN 2229-5518

REFERENCES

[1] Mingzhen Zheng , Xianran Xing, Jinxia Denga, Lu Lia, Jie Zhao, Lijie Qiao , Chunying Fang, “Synthesis and characterization of (Zn, Mn)TiO3 by modified sol–gel route”, Journal of Alloys and Compounds 456, 353–357, 2008.

[2] H. Mandai, Y. Sakabe, and J.P. Canner, “Microstructure

and Microwave Dielectric Properties of Modified Zinc

Titanates (I)”, Ceram. Trans. 15, 313, 1990.

[3] Hyo Tae Kim, Seong Ho Kim, Sahn Nahm, Jae Dong Byun,

Yoonho Kim, “Low-Temperature Sintering and Microwave Dielectric Properties of Zinc Metatitanate- Rutile Mixtures Using Boron”, Journal of the American Ceramic Society,82(11),3043-3048, 1999.

[4] Chaouchi Ahcéne, Kennour Sadia, D'Astorg Sophie,

Marinel Sylvain, Aliouat Mohamed, “Low temperature sintered ZnTio3 dielectric ceramics with temperature coefficient of dielectric constant near zero”, Br. Ceram. Trans. J., 89, 39-43, 1990.

[5] H. Crremoolanadhan, M.T. Sebashan, P. Mohanan, “High permitivity and low loss ceramics in the BaOSrO-Nb2O5 system”, Mater. Res. Bull., 30, 653–658, 1995.

[6] Eung Soo Kim, Chang Jun Jeon, “Microwave dielectric properties of ATiO3 (A = Ni, Mg, Co, Mn) ceramics”, Journal of the European Ceramic Society, 30, 341–346, 2010.

[7] Zhi-Qiang Song, Shu-Bo wang, Wei Yang, Mo Li, Hao Wang, Hui Yan, “Synthesis of manganese titanate MnTiO3 powders by a sol–gel–hydrothermal method”, Material Science and engineering B 113, 121-124, 2004.

[8] Guo Wei Zhou, Young Soo Kang,”Synthesis and structural properties of manganese titanate MnTiO3 nanoparticle”, Materials Science and Engineering C, 24, 71–74, 2004.

[9] N. Mufti, G. R. Blake, M. Mostovoy, S. Riyadi, A. A.

Nugroho, and T. T. M. Palstra, “Magnetoelectric coupling in MnTiO3”, Phys. Rev. B 83, 104416, 2011.

[10] J. Goldstein, Scanning electron microscopy and x-ray microanalysis. Kluwer Adacemic/Plenum Pulbishers, NewYork, 2003.

[11] L. Reimer, Scanning electron microscopy: physics of image formation and Microanalysis, Springer, Germany,

1998.

[12]. R. F. Egerton, Physical principles of electron microscopy: an introduction to TEM, SEM, and AEM, Springer, NewYork, 2005.

[13] S.K. Manik, S.K. Pradhan, “Preparation of nanocrystalline microwave dielectric Zn2TiO4 and ZnTiO3 mixture and X- ray microstructure characterization by Rietveld method”, Physica E 33, 69–76, 2006.

IJSER © 2013 http://www.ijser.org