International Journal of Scientific & Engineering Research, Volume 5, Issue 12, December-2014 977

ISSN 2229-5518

Soil Sub- grade Improvement Using Human

Hair Fiber

Wajid Ali Butt1*, Karan Gupta2, Hamidullah Naik3, Showkat Maqbool Bhat4

*Corresponding Author @ wajid2643@gmail.com Cell: 09797286996

ABSTRACT:-Accumulation of solid waste requires a large area for its disposal. Human hair fiber (HHF) a non- degradable matter is creating an environmental problem so its use in soil improvement can minimize the problem. Also human hair fiber available in abundance at a very low cost. The main purpose of this research is to understand and investigate the variations in the strength of the cohesive soils using human hair fibers (natural fiber) as a soil reinforcing material. The study also includes the determination of the optimum reinforcement in terms of fiber content and length. The HHF randomly mixed in clayey soil samples were tested for its engineering property (Strength) by performing CBR tests on a number of samples by using the different percentage of fibers and comparing the results with the non-reinforced soil. Fibers of different length and equivalent diameter were used with an aspect ratio ranged from 295 to 500. The test result reveals that the strength significantly improves with the inclusion of HHF and also prevents the sample from cracking. Moreover an environmental concern is also included by utilization of waste human hair fiber materials and they can be made useful for improving the soil characteristics and to solve the problems related to the disposal of waste human hair fibers material.

Key Words: Human Hair fiber, Environmental pollution, Waste material, Sustainable material, Soil improvement, clay.

—————————— ——————————

Quite often, engineers may encounter situations where the selected site is not found suitable to take the load of the proposed structure. In such cases, various methods of ground improvement can be used to improve the ground conditions. The main objective of the ground improvement is to improve the characteristics of the soil at the site. Ground improvement is a rapidly developing field because good sites for construction are becoming limited day to day. The geotechnical engineer has the challenge of construction of foundation at the sites which are previously considered unsuitable and unacceptable.

The presence of plant roots is a natural means of incorporating randomly oriented fiber inclusion in the soils. These plant fibers improve the strength of the soils and the stability of

the natural slopes. There are several examples of reinforcing the soil like Great Wall of China (Branches of trees as soil reinforcement), Ziggurats of Babylon (Woven mats of read were used) etc.

———————————————

• 1: Faculty, Deptt of Civil Engineering BGSB University Rajouri, J&K India

• 2: Research Scholar, Deptt of Civil Engineering GNDEC Ludhiana, Punjab India

• 3: Faculty, Deptt of Civil Engineering BGSB University Rajouri, J&K India

• 4: Faculty, Deptt of Civil Engineering University Polytechnic

Rajouri, J&K India

The geotechnical engineers design foundations and other structures on the soil after investigation of the type of soil, its characteristics and its extent. If the soil is good at shallow depth below the ground surface, shallow foundation such as footing and rafts are generally most economical

However if the soil just below the ground surface is not good but a strong stratum exist at a great depth, deep foundation such as piles, wells and caissons are required. Deep foundations are quite expensive and are cost effective only where the structure to be supported is quite heavy and huge. Sometimes the soil conditions are very poor even at greater depth and is not practical to construct even deep foundation. In such cases various methods of soil improvement (stabilization) and reinforcement techniques are adopted. The objective is to improve the characteristics at site and make soil capable of carrying load and to increase the shear strength, decrease the compressibility of the soil.

Synthetic materials like geotextiles, geomembranes, geogrids, geocomposits etc have successfully been used in recent times for reinforcing the soil to improve their stability. The soil can be stabilized by introducing thin strips in it. In the reinforced earth, thin metal strips or strips of wire, hair or geosynthetics are used as reinforcement to reinforce the soil. The essential feature of the reinforced earth is that friction develops between the reinforcement and the soil. By means of friction the soil transfer the forces built up in the earth mass to the reinforcement. Thus

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 12, December-2014 978

ISSN 2229-5518

chosen as reinforcement material and it was randomly included in

to the clayey soils with different plasticity indexes at five

tension develops in the reinforcement when the soil mass is subjected to shear stresses under loads.

Since the advent of the fiber reinforcing of concrete in the

1940’s a great deal of testing has been conducted on the various fibrous materials to determine the actual characteristics and advantages for each product. It is designed to give optimal performance characteristics for the given set of materials, usage and exposure conditions, consistent and parallel with the requirement of cost service, life and durability. Many types of fibers were used and tested (asbestos, steel, glass, synthetics etc). As natural fibers horse hairs were used in motor and straw for mud bricks and many plant types like sisal, coir, bamboo, jute, rice husk, elephant gross etc., were also used.

The objective of this research is to identify a natural fiber to understand and investigate the variation of the strength of the cohesive soil using human hair fibers randomly mixed with the soil samples. The various soil samples with different densities and moisture content were tested. The main objective of this study is to investigate the suitability of solid waste materials such as human hair fibers in the process of soil stabilization as a reinforcement which can replace conventional commercial fiber materials. The study also include a proposed protection method to increase the durability of the selected fiber, determination of the optimum reinforcement scheme in terms of fiber content and length. Moreover an environmental concern is also included by utilization of human hair fiber materials and they can be made useful for improving the soil characteristics and to solve problems related to the disposal of waste human hair fibers material.

The concept of randomly reinforced soil is relatively new in geotechnical engineering but the reinforcement of clay soils with natural fibers has been practiced from the time of Pharaohs (Estabragh et al 2011).s Recently soil reinforcement with short, discrete, randomly oriented fibers is getting more attention from many researchers around the world. Extensive studies were carried out on the stabilization of soft clays and expansive clays using various additives such as lime, cement, synthetic and natural fibers. Ranjan et al. (1994) conducted a series of tri-axial tests to study the behavior of Plastic Fiber Reinforced sand. Maher & Ho (1994) investigated the mechanical properties of a Kaolinite/fiber composite in unconfined compression tests. Kaniraj et al. (2003) conducted an experimental study to investigate the influence of randomly oriented fiber inclusions on the geotechnical behavior of two Indian fly ashes. Akbulut et al. (2007) evaluated the use of waste materials such as scrap tire rubber, polyethylene, and polypropylene fiber for the improvement of strength and dynamic behavior of clayey soils. In the investigation done by S A Naeini and S M Sajadi (2008), The waste polymer materials has been

different percentages of fiber content (0%, 1%, 2%, 3%, 4%) by weight of raw soil. CBR tests are conducted by Behzad Kalantri, Bujang B K Haut and Arun Prasad, (2010) and their experimental findings are analyzed with the point of view of use of waste plastic fibers in soil reinforcement. Effect of random fiber inclusion on Consolidation, Hydraulic conductivity, Swelling, Shrinkage limit and Desiccation Cracking of clays (Mahmood R. Abadi, Ali Parsapajouh, and Mohammad A. Arjomand, (2008)) point to strength and settlement characteristics of the reinforced soil and compared with unreinforced condition. The effect of polypropylene fiber inclusion into soil in the improvement of soil behavior through a series of experimental investigations was established by many scholars (Dall’Aqua et al. 2010; Jiang et al.

2010; Senol, 2011).

Estabragh (2011) investigated the effects of fiber on the consolidation and shear strength behavior of a clay soil reinforced with nylon fibers. The effective use of natural fibers as reinforcement was proved by several researches. Basha et al. (2004) conducted study on stabilization of residual soils by chemically using cement and rice husk ash. Akhtar et al. (2008) studied the influence of Fly ash mixed with lime having varying percentage of human hair fibers in California Bearing Ratio values. Akhtar and Ahamad (2009) studied the effect of hair fiber on mechanical properties of fly ash based hollow block for masonry structures. Ramesh et al. (2010) described the compaction and strength behavior of black cotton soil (BC soil) reinforced with coir fibers.R.R Pillai and A Ramathan et al (2012) describes the index properties of soil using human hairs. However, it is found that studies on the use of human hair fibers in the stabilization of soils as reinforcement have not been reported so far, which is attempted in our study.

2.1. Material used

2.1.1 Soil

The soil used the present study is clayey in nature. Laboratory tests for index and engineering properties were conducted according to IS methods of testing.

2.1.2 Human Hair Fiber

These fibers are considered as value less solid wastes which creates environmental problems because of being non- biodegradable in nature. The length of these fibers varies from 5 to 50 mm generally. The aspect ratio varies from 290 to 500. These fibers are available all over the world with very less cost.

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 12, December-2014 979

ISSN 2229-5518

the optimum moisture content at the different percentages of the human hair fiber (0%, 0.5%, 1%, 1.5%, 2%, 2.5%). CBR tests

The tensile strength of the fibers are also high. The properties of these fibers are given in table 2

Property | Value |

Natural moisture content | 12.36% |

Specific gravity | 2.48 |

Liquid Limit | 24.8% |

Plastic Limit | 21.42% |

Plasticity Index | 3.38% |

Liquidity Index | -1.5 |

Relative consistency | 2.5 |

Flow Index | 6.64 |

Toughness index | 0.51 |

Shrinkage Limit | 12.68% |

Maximum Dry Density | 1.84 gm/cc |

Optimum moisture content | 14% |

Compression Index | 0.08 |

CBR at OMC | 6.63% |

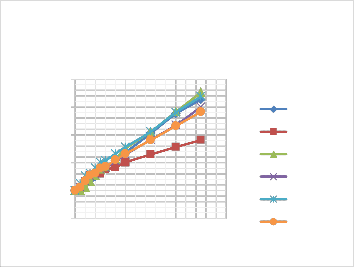

(un-soaked) were carried out at MDD and OMC at the different percentages of the fiber content. The CBR test were conducted quickly so that the moisture may not lost. The plunger in the CBR test penetrates the specimen in the mould at a rate of 1.25 mm per minute.

Effect on Compaction and CBR characteristics

Proctor’s standard test was carried out to determine the maximum dry density and optimum moisture content with different percentages of fiber content taken in terms of weight, and found that at 0.25% of the fiber MDD increases and OMC decreases. But after increasing the fiber content percentage reverse happens i.e MDD decreases and OMC increases. It is due to the fact that the soil particles rearranges itself with the randomly oriented fibers and secondly the heavier material is

Property | Remark |

Cross-Section | Circular |

Diameter | 17-100 µm |

Length | 5-50 mm |

Elongation | 1.5 times its dry weight |

Tensile strength | Equal to Copper wire of similar diameter |

Outer Covering | Cuticle |

Protein Present | Keratin |

2.2 Preparation of samples

All the samples were prepared at the OMC and MDD with different percentages of fiber content i.e 0%, 0.5%, 1%, 1.5%,

2%, 2.5%. Fibers were mixed to the air dried soil. Addition of fibers was done very carefully and percentage is calculated by weight.

2.3 Laboratory Tests

Proctor’s standard compaction was carried out as per IS: 2720 (Part VII) for the determination of the maximum dry density and

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 12, December-2014 980

ISSN 2229-5518

1.8

1.7

1.6

1.5

1.4

10

Trial 1 8

Trial 2 6

0.0 1.0 2.0 3.0 4

2

Fiber Content (% )

0

Fig:- Showing variation of MDD with Fiber Content

0 0. 5 1 1. 5 2 2. 5 3

Human Hair Fiber in %

4000

3000

2000

1000

0

0% Fiber

0.5% Fiber

1% Fiber

1.5% Fiber

• By increasing the human hair fiber content percentages

MDD decreases and OMC increases.

• CBR value at 0.5% fiber content is much less than unreinforced soil. But after increasing the fiber content percentage CBR value increases upto 2 percent of fiber, then again starts decreasing at 2.5 percent fiber content.

• For avoiding the balling of the hair fiber more studies are required to find randomly mixing methods of the fiber without balling effect so that better results are obtained in the future.

0. 00 5. 00 10. 00 15. 00

-1000

PENETRATION IN MM

2% Fiber

2.5% Fiber

Fig:- Load Vs Penetration Curves for different fiber contents

[1] *Akbulut, S., Arasan, S. and Kalkan, E. (2007). “Modification of clayey soils

[2] using scrap tire rubber and synthetic fibers.” Applied Clay Science. [3] Akthar, J.N., Alam, J. and Ahmad, Sh. (2008). “The influence of

randomly

[4] oriented hair fiber and lime on the CBR value of Dadri fly ash.” Asian Journal

[5] of Civil Engineering (Building and Housing).

[6] Akthar, J. N.,Ahmad, Sh. (2009). “The effect of randomly oriented hair fiber on

[7] mechanical properties of fly ash-based hollow block for low height masonry

[8] structures.” Asian Journal of Civil Engineering.

[9] Basha, E. A., Hashim, R., Mahmud, H. B. and Muntohar, A. S. (2004).

[10] “Stabilization of residual soil with rice husk ash and cement.” Construction and

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 12, December-2014 981

ISSN 2229-5518

[11] Building Materials.

[12] Estabragh, A. R., Bordbar, A. T. and Javadi, A. A. (2011).

“Mechanical

[13] behaviour of a Clay soil reinforced with Nylon fibers.” GeotechGeol Eng.

[14] Kaniraj, S. R., and Gayathri, V. (2003). “Geotechnical behavior of fly ash mixed

[15] with randomly oriented fiber inclusions.” Geotextiles and

Geomembranes.

[16] Ramesh, H. N., Krishnan, K. V. M. and Mamatha, H. V. (2010). “Compaction

[17] and strength behaviour of lime-coir fiber treated Black Cotton soil.”

[18] Geomechanics and Engineering.

[19] Senol, A. (2011). “Effect of fly ash and polypropylene fibers content on the

[20] soft soils.”

IJSER © 2014 http://www.ijser.org