International Journal of Scientific & Engineering Research, Volume 3, Issue 7, July-2012 1

ISSN 2229-5518

Simulation Study of GAGD process in One of

Iranian Fractured Reservoir

Naser Akhlaghi1, Fatemeh Rezaei2, Nima Akhlaghi3

1,3Department of Petroleum Engineering, Omidiyeh Branch, Islamic Azad University, Omidiyeh, Iran.

2Department of Elementary Education, Omidiyeh Branch, Islamic Azad University, Omidiyeh, Iran.

Abstract— In gas injection EOR methods the oil recovery is controlled by the rates of injected gas and oil production, relative perm eability, heterogeneity and balance among viscose, capillary and gravity forces. In the GAGD process gas injects in the crest and the l ayer that is located between oil and gas zone and provides gas-oil gravity mechanism. This research investigates the effect of optimum place to explore the injection well in GAGD process and future more the status of injection well which includes vertical, deviation an d multilateral model. Results indicate the total oil production in multilateral production well has the best efficiency in comparison with deviation and vertical injection well.

Key Words— Gravity Drainage, Reservoir Simulation, Gas Injection, Horizontal Well, GAGD, EOR, Fractured Reservoir

—————————— ——————————

1 INTRODUCTION

nhanced Oil Recovery (EOR) surveys from 1980-2004 show that gas injection projects have been rapidly increas- ing [1]. EOR by gas injection currently accounts for about

48% of total enhanced production and for the majority of light oil enhanced production. The petroleum industry has been trying to improve gas injection EOR performance for several years to overcome problems due to unfavorable flood mobility ratios such as gas gravity override and premature gas break- throughs. The Water-Alternating-Gas (WAG) process, intro- duced by Caudle and Dyes [2], is the most widely used gas flood conformance control tool in horizontal type gas injection projects. In spite of WAG being a sound concept to counter gas gravity override and its reasonable performance in the labora- tory tests, industry experience [3] shows that the incremental oil recovery (over primary depletion or after secondary water- flood) by WAG application has only been between 5 to 10% IOIP. On the other hand, gravity-stable gas injection floods, predominantly applied in dipping reservoirs and pinnacle reefs, have demonstrated recoveries in the range of 40 to 95% Residual Oil in Place (ROIP) field incremental oil recoveries [4].

The effect of gravity tends to segregate fluids in the reservoir

in order to maintain the density equilibrium [5]. Gravity se-

gregation of fluids in horizontal reservoirs often leads to gas

override and gas coning problems during a gas injection

process.

Recent advances in horizontal well technology have demon-

strated that the use of horizontal wells could minimize prob- lems such as gas override and gas coning. Moreover, the use of horizontal wells in naturally fractured reservoirs often re- sults in higher productivity. Horizontal wells could find fa-

vorable prospects in gravity stable gas injection processes in horizontal reservoirs.

The force of gravity is believed to provide sufficient mechani- cal energy to drain a large percentage of oil from the rock. However, the major concern is not how much potential me- chanical energy the reservoir can supply to facilitate gravity

drainage but how effective this mechanical energy would be in displacing and mobilizing the reservoir oil [6, 7].

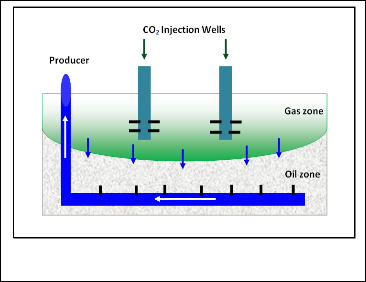

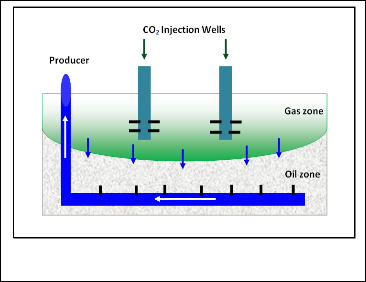

The GAGD process [8] uses several existing vertical gas injec- tors to inject gas in the crest of the reservoir, whereas the hori- zontal producer placed at the bottom facilitates production of drained oil. The GAGD process utilizes the natural density contrast between the injected gas and the reservoir oil to en- hance the drainage of oil towards the horizontal producer. This gravity stable displacement results in significantly im- proved volumetric sweeps, consequently resulting in lower residual oil saturations. Schematic of GAGD process is shown in Figure 1.

Fig. 1. Schematic of gas assisted gravity drainage (GAGD) process [9]

The GAGD process has been found to be largely immune to the deteriorating effects of reservoir heterogeneity, and the results indicate that the presence of vertical fractures possibly aids the GAGD performance.

1 Corresponding Author, E-Mail: Naserakhlaghi@yahoo.com, Mailing Address: Department of Petroleum Engineering, Omidiyeh Branch, Islamic Azad University, Omidiyeh, Iran.

IJSER © 2012

http://www.ijser.org

The research paper published by IJSER journal is about Simulation Study of GAGD process in One of Iranian Fractured Reservoir 2

ISSN 2229-5518

Along with edge water drive and solution gas drive, gravi- ty drainage has long been recognized as one of the three im- portant natural drive mechanism for expelling oil from the reservoir rock. However, the quantification of oil recovery due to drainage has long been a concern. It has long been a con- cern to identify the contribution of oil recovery due to gravity drainage alone. During the early life of the reservoir, the re- servoir tends to produce by solution gas drive, depending upon how much pressure drawdown is available. Although, the primary mechanism is solution gas drive, some drainage is still evident in the reservoir during production period at the lower part of the reservoir. However, when the reservoir pres- sure depletes, gravity drainage seems to be taking place at greater portions of the reservoir [10].

2 RESERVOIR DESCRIPTION

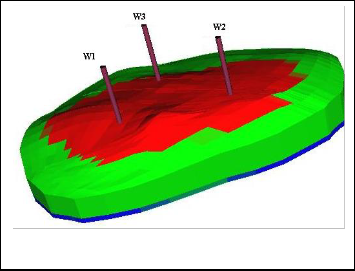

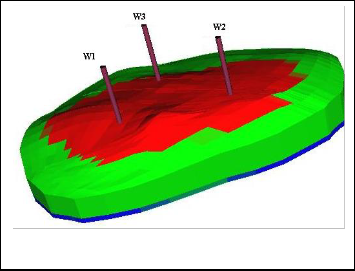

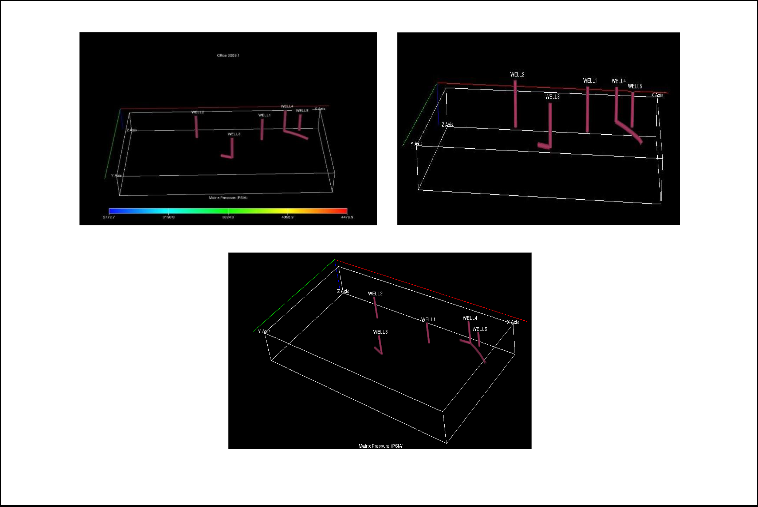

This reservoir is undersaturated and a fractured reservoir that production is achieved only by fractures. All of the wells in this reservoir were produced in 1999 (figure 2).

4 RESULTS

In this case study, because of the reservoir has reached to end of primary recovery, applying one of EOR methods is neces- sary. As properties of fluid and rock correspond to light and fracture media, GAGD is more suitable method that should be considered.

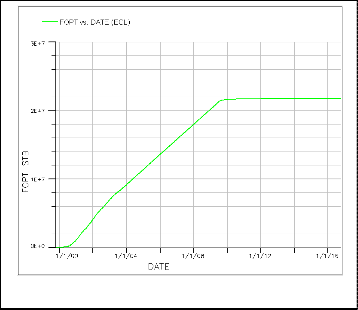

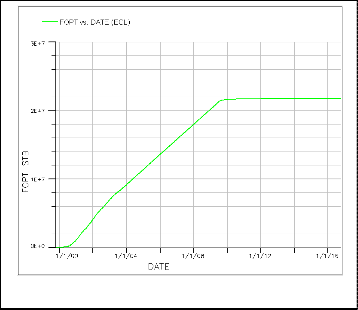

Figure 3 shows the total oil filed production at pressure deple- tion scenario from the year of 1999 to 2016. As it is seen until the year of 2010, cumulative oil production is increasing and after that the slope of graph tends to constant production and reservoir faced to half-time of its life. This figure indicates the field faces to reduction of oil and need to apply EOR methods.

Fig. 3. Cumulative oil recovery in pressure depletion scenario

Fig. 2. Map of reservoir

3 MODEL DESCRIPTION

The model of reservoir was built in Black oil-Eclipse simulator. Geometry properties such as (porosity, permeability in three directions and net to gross) for each cell were fed into reser- voir model. The various parameters of selected reservoir are listed in Table 1. The numbers of grids are 3240.

TABLE 1. General Data of the Reservoir

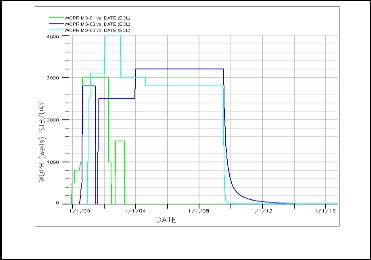

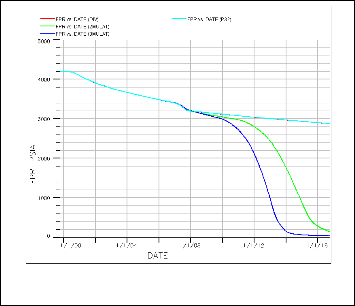

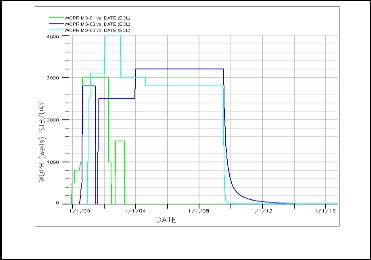

Figure 4 illustrates the rate of oil production for each well. As it is seen the rate production is decressing during 2010-2016. Thus this reservoir need to investigation of EOR methods to increase the amount of oil production.

Fig. 4. Wells oil production rate in pressure depletion scenario

1 Corresponding Author, E-Mail: Naserakhlaghi@yahoo.com, Mailing Address: Department of Petroleum Engineering, Omidiyeh Branch, Islamic Azad University, Omidiyeh, Iran.

IJSER © 2012

http://www.ijser.org

The research paper published by IJSER journal is about Simulation Study of GAGD process in One of Iranian Fractured Reservoir 3

ISSN 2229-5518

To apply EOR method for this reservoir, Gas Assisted Gravity Drainage (GAGD) method was selected to improved oil pro- duction rate. So 50 scenarioes with one horizontal production well and one CO2 gas injection well were studied to investi- gate the effect of pattern in this method.

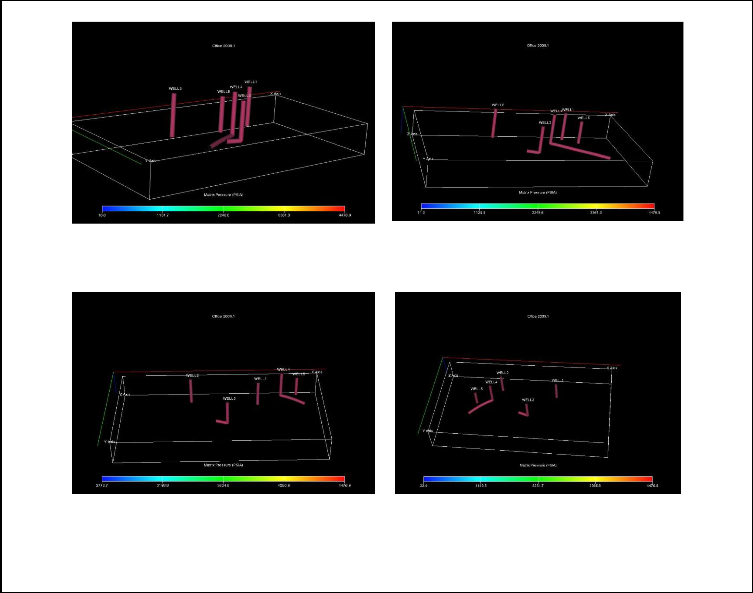

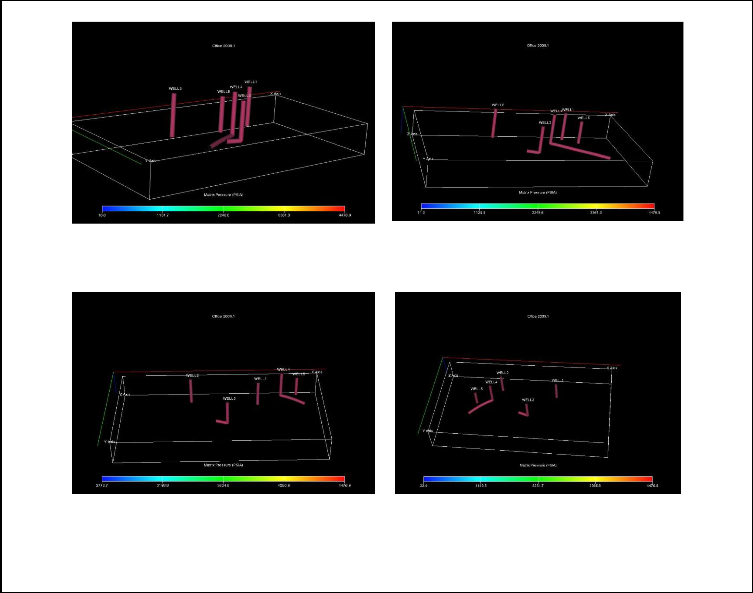

Figure 5 explains several patterns that were applied to obtain this purpose which parts a and b were not good pattern while patterns c and d have larger oil production and the less pres- sure drop but pattern c was caused to slightly pressure drop.

(a) (b)

(c) (d)

Fig. 5. Several patterns that were selected to investigate the effect of patterns

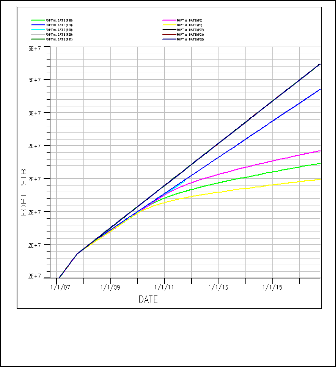

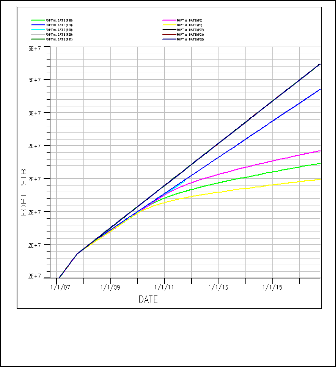

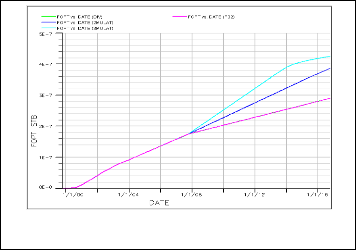

Figure 6 and 7 illustrate field pressure rate and cumulative oil production for several scenarios that have maximum and min- imum field pressure rate.

It can be seen after the year of 2008 the suitable and unsuitable patterns were going to separate from together and it is in- creaing with pass of time. So that the pattern that was shown in Figure 5(c) was selected inorder to consider four other sce-

narios that include the variety types of production well in GAGD technique: horizontal well, deviation well, multilatral well with 2 and 3 branches.

1 Corresponding Author, E-Mail: Naserakhlaghi@yahoo.com, Mailing Address: Department of Petroleum Engineering, Omidiyeh Branch, Islamic Azad University, Omidiyeh, Iran.

IJSER © 2012

http://www.ijser.org

The research paper published by IJSER journal is about Simulation Study of GAGD process in One of Iranian Fractured Reservoir 4

ISSN 2229-5518

5 SELECTION OF PRODUCTION WELL CONFIGURATION DURING GAGD PROCESS

As mentioned before, the best pattern, with high cumolative oil productin and low pressure drop, was choosen from 50 scenarios. In this section the configuration of production well was changed to reach the most suitable conditions.

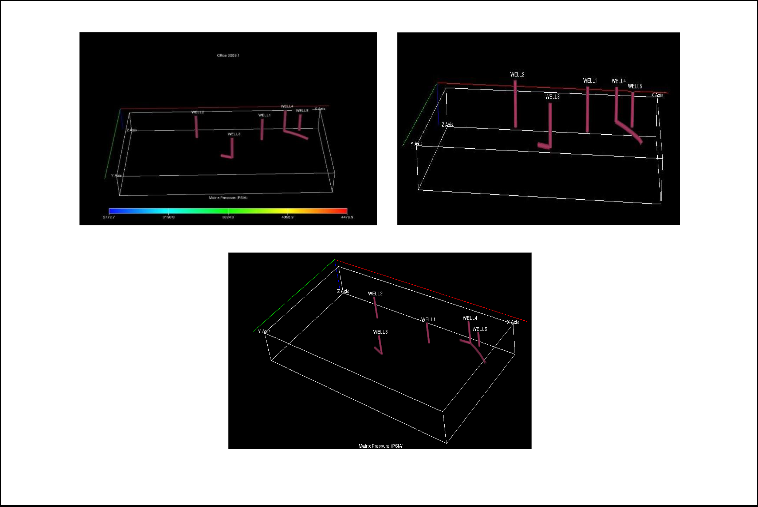

Figure 8 indicates production well in state of horizontal, divia- tion, and multilatral.

Fig. 6. Field pressure rate for several scenarios

Fig. 7. Cumulative oil production in the cases of vertical, deviation and multilateral injection well

1 Corresponding Author, E-Mail: Naserakhlaghi@yahoo.com, Mailing Address: Department of Petroleum Engineering, Omidiyeh Branch, Islamic Azad University, Omidiyeh, Iran.

IJSER © 2012

http://www.ijser.org

The research paper published by IJSER journal is about Simulation Study of GAGD process in One of Iranian Fractured Reservoir 5

ISSN 2229-5518

(a) (b)

(c)

Fig. 8. (a) the best pattern of horizontal well that was selected in last section (b) deviation form of production well (c) multilatral form of production well

After gaining the sufficient pattern and production well loca- tion, the second step evaluates the configuration of production well. For considering the effect of multilateral (2branches), and multilateral (3branches), deviation and horizontal mode of production well, four scenarios were performed.

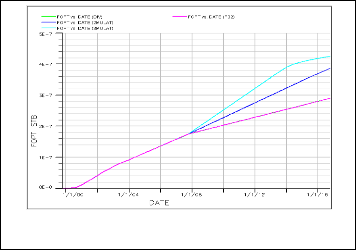

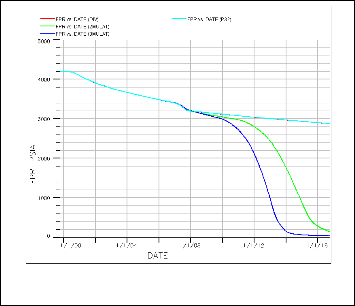

Figure 9 display the total field oil production for these sce- narios.

As we can see the rates of total oil production after the year of

2008 are seperated from togher and the amount of multilatral

well with 3 branches is more than other and the amount of horizontal and deviation well is nearly equal.

Figure 10 shows field pressure for four types of production wells between 1999- 2016. It can be seen that the pressure of field is going to zero for multilatral well (2&3 branches) after the year of 2016 but for horizontal and deviation wells is not in this way.

Fig. 9. Total field oil production at horizontal, deviation, multilateral

(2&3 branches)

1 Corresponding Author, E-Mail: Naserakhlaghi@yahoo.com, Mailing Address: Department of Petroleum Engineering, Omidiyeh Branch, Islamic Azad University, Omidiyeh, Iran.

IJSER © 2012

http://www.ijser.org

The research paper published by IJSER journal is about Simulation Study of GAGD process in One of Iranian Fractured Reservoir 6

ISSN 2229-5518

[8] Rao, D. N., “Development and Optimization of Gas Assisted Gravity Drainage (GAGD) Process for Improved Light Oil Recovery”, U S- DOE Proposal, July 2001.

[9] Akhlaghi, N., Kharrat, R., Mahdavi, S., “Gas Assisted Gravity Drai- nage by CO2 Injection”, Journal of Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, June 2012.

[10] Lewis, O.J., “Gravity Drainage in Oil Fields,” Trans. AIME, volume

155, pp. 133, 1944.

Fig. 10. Field pressure rate at horizontal, deviation, multilateral (2&3 branches)

5 CONCLUSION

1. The rate of oil production in this studied reservoir reach to low amount and applying of one of EOR methods that is suit- able for it is vital.

2. As the fluid and rock of this reservoir indicate it is light and fractured, this is a good choice to inject gas with assisted of gravity drainage mechanism.

3. Number of 50 GAGD scenarios performed to find out the best location and pattern of production well.

4. Configuration of wells had affected on performance of GAGD process. So some type of well states which are horizon- tal, deviation, multilateral (2 & 3 branches) was investigated.

5. In this reservoir, results indicate, multilateral (3 branches),

multilateral (2 branches), horizontal and deviation production

well have high oil recovery respectively.

REFERENCES

[1] Moritis, G., Enhanced Oil Recovery Biannual Surveys, OGJ, 1984 - 2004.

[2] Caudle, B. H. and Dyes, A. B., “Improving Miscible Displacement by Gas-

Water Injection” Transactions of AIME, 213 (1959), 281-284.

[3] Christensen, J. R., Stenby, E. H and Skauge, A., “Review of WAG field experience”, SPE 71203, presented at 1998 SPE IPCE, Villhermo- sa, Mexico, Mar 3 - 5, 1998.

[4] Rao, D. N., Ayirala, S. C., Kulkarni, M. M., Sharma, A. P., “Develop- ment of the Gas Assisted Gravity Drainage (GAGD) Process for I m- proved Light Oil Recovery”, SPE 89357, Presented at SPE/DOE 14th IOR Symposium, Tulsa, OK, Apr 17-21, 2004.

[5] Muskat, M., “Physical Principles of Oil Production” McGraw-Hill, New

York, 1949.

[6] Lewis, O. J., “Gravity drainage in Oil Fields,” Trans. A.I.M.E., vol.

155, 1942.

[7] Oren, P. E., Pinczewski, W. N., “Fluid distribution and pore scale

displacement mechanism in drainage dominated three phase flow,”

TIPM, 6:105-133

1 Corresponding Author, E-Mail: Naserakhlaghi@yahoo.com, Mailing Address: Department of Petroleum Engineering, Omidiyeh Branch, Islamic Azad University, Omidiyeh, Iran.

IJSER © 2012

http://www.ijser.org