International Journal of Scientific & Engineering Research, Volume 4, Issue 8, August-2013 823

ISSN 2229-5518

Real Time Object Visual Inspection Based On

Template Matching Using FPGA

GURURAJ.BANAKAR Electronics & Communications S J B Institute of Technology,

Bangalore, India

Gururaj.bnk@gmail.com

RAVIKUMAR.A.V Electronics & Communications S J B Institute of Technology, Bangalore, India

ravi_sjb@rediffmail.com

Abstract— In similarity measure, normalized cross-correlation has found application in broad range of in image processing. This work proposes a novel technique aimed at improving the performance of exhaustive template matching based on NCC. An effective sufficient condition, capable of rapidly pruning those cross correlation score with respect to the current best candidate, can be obtained exploiting an upper bound of the NCC function. In this work Real-Time FPGA accelerates time consuming NCC template matching was presented. With this type of template matching we can inspect any industrially manufactured product on its production line with high accuracy, with increased speed of matching where huge amount of production is concerned. We got good results by reducing search window size by reducing complexity in matching template.

Keywords— FPGA, Normalized cross-correlation, Search window, Template

I. INTRODUCTION

In similarity measure, due to its invariance to linear brightness and contrast variations, NCC has found application in a broad range of image processing such as target recognition, satellite image monitoring, stereo vision, medical diagnosis, pattern recognition and template matching. But compared to other methods NCC is relatively simple and has good accuracy. The complexity in template matching increases with real-time applications for fast image process.

Matching a template sub-image into a given image is a ubiquitous task occurring in countless analysis applications. The basic template matching algorithm consists in sliding the template over the search area and, at each position, calculating a distortion or correlation, measures estimating the degree of dissimilarity or similarity between the template and source image. Then, the maximum correlation, position is taken to represent the instance of template into the image under examination.

Since with large size images or templates the matching process can be expensive, numerous techniques aimed at speeding up the basic approach have been devised. Among the general techniques, the major one are a) the use of multi-

resolution schemes, b) sub-sampling the image and the template, c) two-stage matching. Since these techniques do compare the full resolution image with full resolution template at every search position and can be trapped by local extremes resulting in wrong localization of the template under inspection. In some cases like SEA( Successive Elimination Algorithm) and PDE( Partial Distortion Elimination) allow for notably speeding up the computer up the computation required by an exhaustive-search template matching process. SEA skips the position without calculating the actual position.

The main advantage of the normalized cross correlation over cross correlation is that it is less sensitive to linear changes in the amplitude of illusion in the two compared images. The NCC does not have a simple frequency domain expression. Its computation time dramatically increases as the window size increases. Here we discussed with problems and solutions for fast image processing as applicable to industrial production.

II. PRAPOSED METHOD

The proposed method of template matching with modified

NCC algorithm and method of processing as follows

A. Process overflow

The proposed system works with the help of Matlab, Xilinx software. At first the image is captured from camera. Because of FPGA cannot understand the image format, the image pixels are converted into text format by using Matlab . Matlab mainly use for selecting template, converting 2D image into bits form and finally to display the matched image. As we know Xilinx is used in most of the FPGA processing, NCC algorithm is developed on it. Xilinx 12.2 will increase speed of execution in matching template on target image and the resulting wave forms will showed in Modelsim simulator.

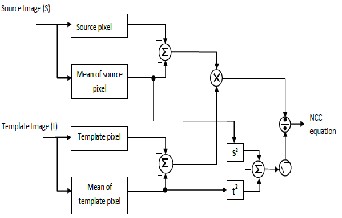

B. NCC design

Normalized cross-correlation is process of sliding one image over the other for matching in target image. As the search window size increases the computation complexity

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 8, August-2013 824

ISSN 2229-5518

increases. In order to overcome from this complexity and to increase the speed of execution we redesigned the formula as follows![]()

NCC= ( S − S� ) ( 𝑡 − 𝑡 )

�S� ²+ 𝑡 ²

Here the S represents the source image, S� is mean of source image, t is template and t is the mean of template

image. By designing this algorithm on Xilinx we have good

results with less time consumption. This can be show in Fig.1 below

Fig. 1 NCC block diagram

In template matching we should consider the external parameters like brightness, noise and object position in image when we are capturing image from any industry for product inspection. In order to come over from this difference we are calculating the mean of each pixel for best cross-correlation. During template matching , the template slides pixel-by-pixel in the search window to determine the most similar image block in the target image. The ideal process of template matching is shown graphically in Fig.2 below

Fig.2 Template matching

When the template matching process begins the search window slides on the target image which is of size 64x64 and the target image size of 256x256. The NCC algorithm is designed to find the maximum matching pixel or to its threshold level. The design is in such way if matches does not found then that pixel will be rejected for its further process. When the pixel matches the Xilinx will store in memory and pixel below threshold level will be rejected and is considered here as zero. The process is continued from the top left of the image till to end of target image for best matching with template . During image loading Xilinx will not take more time as well as in matching The process flow is show in Fig.3 below

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 8, August-2013 825

ISSN 2229-5518

Fig.3 Flow graph of template matching

A typical parameter of template matching algorithm is a threshold on minimum correlation value yielding a valid match. This value allows for discriminating when an instance of the template is present or not in the image under examination. As we discussed earlier that when the search window size increases the complexity increases. In our design we examined on 64x64 search window size for fast matching of object in image for both good quality and defected object which are discussed in results.

The basic requirements for our paper are tabulated below

TABLE I. NCC SPECIFICATIONS

Template Image size | 64 x 64 |

Target Image size | 256 x 256 |

Search window size | 64 x 64 |

Computing time | < 5ms |

System bus width | 8-bit |

Targeted platform | Xilinx 12.2 |

We have worked on various images for best template matching and to display the final results on Matlab which shows the detected object which matching the original image. In comparison with other algorithm NCC can match the image irrespective of position of object within search window.

III. EXPERIMENTAL RESULTS

In this experiment, the image data width are input to the system which same for both the template and target image. The color image is converted into gray scale on matlab and then converted into text( 0’s & 1’s). Xilinx software is used for coding NCC algorithm. The device utilization of FPGA is listed in Table II. below

TABLE II. DEVICE UTILIZATION SUMMARY

The method of selecting template from source image, reading target image and processing it on Xilinx is shown below.

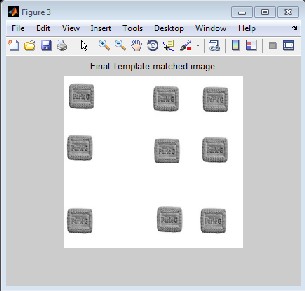

Step 1. First selecting the template image using matlab which is shown in Fig.4 below

Fig. 4 Selected Template Image

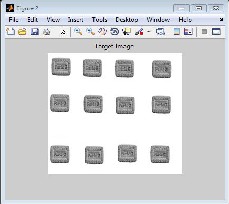

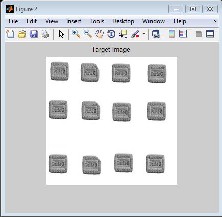

Step 2. Now select the target image in which matching the similar objects in image. Fig. 5 have all good objects but Fig.6 have some defected object during manufacturing. These images are experimented one after the other.

Fig. 5 Target image with good products

The number of slices used on FPGA is very less and the percentage of utilization is also reduced. The other parameters can also be seen in the Table II. The time required to image processing will be less than for any kind of images.

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 8, August-2013 826

ISSN 2229-5518

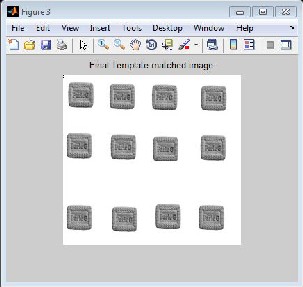

Fig. 6 Target image with defected products

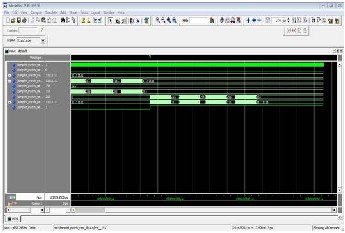

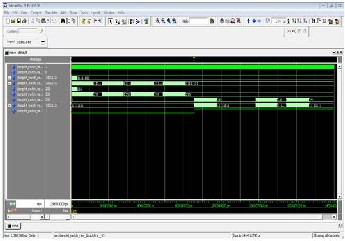

The text image is loaded on Xilinx 12.2 software where it is Reading both the template and target image. This is shown on Modelsim simulator as shown in Fig. 7 and Fig.8 for both target images respectively.

Fig. 7 Final template matched image showing all products

Fig. 8 Final template matched image with defect in some products

It is programed to remove the defected image during process as we can see in Fig. 8

The results in Modelsim simulator are given in Fig.9 and in Fig.10 below in which green color waveforms indicates the read images up to some period and the indicates the template matching process tell the end. In Fig. 10 small empty space during matching indicates defect in object and it is discarded.

Fig. 9 Resulting waveforms in Modelsim of first target image

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 8, August-2013 827

ISSN 2229-5518

ACKNOWLEDGMENT

I would like to articulate my profound gratitude and indebtedness to my project guide RAVIKAUMAR.A.V( Asst. Prof. Dept. of ECE. SJBIT) who is always being a constant motivation and guiding factor throughout the project time in and out as well. It has been a great pleasure for me to get a opportunity to work under him.

REFERENCES

Fig. 10 Resulting waveforms with defected products

With these results we draw table which gives the timing requirements for template matching.

TABLE III. Timing Simulations

[1] CHIN, AUTOMATED VISUAL INSPECTION: A SURVEY IEEE PAMI 1982 [2] S. C. Wang, "Human reliability in visual inspection," Quality, Sept.

1974.

[3] Tsai, D.-M., Chiang, C.-H., 2002. Rotation-invariant pattern matching using wavelet decomposition. Pattern Recognition Lett. 23, 191±201.

[4] Wakahara, T., Kimura, Y., Tomono, A., 2001. Affine-invariant recognition of gray-scale characters using global affine transformation correlation. IEEE Trans. Pattern Anal. Machine Intell.

23, 384±395.

[5] Kim, J.H., Cho, H.S., Kim, S., 1996. Pattern classification of solder joint images using a correlation neural network. Eng. Appl. Artif. Intell. 9, 655±669.

[6] Cai, X.Y., Kvasnik, F., Blore, R.W., 1994. Wafer fault measurement by coherent optical processor. Appl. Opt. 33, 4487±4496.

[7] Stefano,”An Efficient Algorithm for Exhaustive Template Matching based on Normalized cross correlation”, IEEE ICIAP03

[8] Xiaotao Wang, Xingbo Wang, "FPGA Based Parallel Architectures

for Normalized Cross-Correlation", The 1st International Conference on Information Science and Engineering (ICISE2009), pp. 225 – 229

[9] Nisheeth Gupta, Nikhil Gupta, "A VLSI Architecture for Image Registration in Real Time," IEEE TRANSACTIONS ON VERY LARGE SCALE INTEGRATION (VLSI) SYSTEMS, VOL. 15, NO.

9, SEPTEMBER 2007

In table template image loading time is same for both process and also for target image. The process timing is bit varied in simulation 1 because of more calculation in target image.

IV. CONCLUSIONS

Here we conclude that a real-time template matching module accelerates time consuming normalized cross-correlation has been presented. NCC algorithm equation is changed in our design for best results and increase the accuracy of matching template in the target image. Compared with previous results the design is very efficient and compact with less utilization of FPGA with less time consumption. This NCC architecture can be best applied in industries where huge amount of production per day. This method can efficiently inspect the product with small changes in product quality. This system can be successfully installable in food product, semiconductor, LED die, Photo voltaic and in PCB inspection. With some changes in this system we can instruct the other system to remove the defected part accurately using robots where human inspection is not possible.

IJSER © 2013 http://www.ijser.org