The shape, size, thickness, laying pattern, etc., are important block parameters. These parameters influence the overall perfor- mance of the pavement. A typical CBP section has been shown in Figure-1.

International Journal of Scientific & Engineering Research, Volume 4, Issue 7, July-2013 782

ISSN 2229-5518

Overview on Structural behaviour of Concrete

Block Pavement

Dr. Mokaddes Ali Ahmed1, Binod Singhi2

Abstract— Concrete Block Pavement (CBP) is getting popularity in areas where normal flexible pavement does not last long. Application of CBP is developing very fast for various reasons such as high resistance to deformation, durability, easy and rapid quality construction, ability to carry traffic immediately after construction, compatibility with the environment and aesthetic features etc.

The structural behaviour of CBP is similar to flexible pavement. However, the performance of CBP depends upon on block shape, size, thickness, type of bedding and jointing sand, joint width. The laying pattern of blocks is also important which affects the overall performance of the CBP. The edge restraint is one of the features which are essential to stop mitigation of the block outward. The interlocking mechanism is one of the unique characteristics of the CBP. The performance of CBP largely depends on how well the interlock has achieved. It is an established fact that the blocks are the structural member of the CBP and is instrumental in load spreading to its neighbour.

Index Terms— CBP, bedding sand, jointing sand, edge restraints, interlock.

—————————— ——————————

ONCRETE blocks are widely used in municipality road appli- cation all throughout the world. It is also commonly used in urban roads, airport taxiway, parking area, port and industrial

area. The concrete block pavement (CBP) is getting popularity in the urban area day by day because the access to the underground utilities is a key requirement in unban road paving. Due to segmental nature of the paving block, the concrete block is easily removed and the under laying utilities could be accessed easily for maintenance works. CBP is preferred as the ideal choice in urban areas.

Literature review on CBP reveals that the block pavement tends to

perform in a manner which is qualitatively similar to conventional flexible pavement. Structural capacity of the various block parame- ters is consistent in performing the functional role as a flexible pavement.

The pavement structure of CBP is mainly consisting of concrete pav- er blocks placed over a uniformly spread and compacted sand beds laid over base course of the pavement structure. The major structural components of the concrete block pavements are;

• Concrete Block Pavers

• Bedding and Jointing Sands

• Edge Restraints

• Base-course and Sub-base

• Sub-grade

The load-spreading capacity of concrete blocks layer depends on the interaction of individual blocks with jointing sand to build up resistance against applied load.

————————————————

• Professor, Department of Civil Engineering, National Institute of

Technology Silchar,Assam India

PH. +919435725087 Email: ali.mokaddes@gmail.com

• Phd. Scholar, Department of Civil Engineering, National Institute of

Technology Silchar,Assam India

PH. +919435071068 Email:bksinghi@gmail.com

The shape, size, thickness, laying pattern, etc., are important block parameters. These parameters influence the overall perfor- mance of the pavement. A typical CBP section has been shown in Figure-1.

Fig.1. Typical cross section of concrete block pavement

Each of the components of CBP is discussed in succeeding par- agraphs. The Base-course, Sub-base and Sub-grade are the common components of flexible pavement. So they are not elaborated in this paper.

The interlocking concrete block pavers are the main load spreading component. The different varieties of shaped blocks are installed in different laying pattern such as stretcher & herringbone pattern. It is important here to mention that laying pattern, joint width, block size and block thickness are the important parameters which influence the overall performance of the interlocking block pavement. The resistance build up on application of load depends on the interaction of individual blocks, jointing sands and thickness of bedding sand. These parameters are utmost important to build-up resistance against deflection or deformation on application of load.

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 7, July-2013 783

ISSN 2229-5518

The study on CBP reveals that the load is being spread through the jointing sands. For a same plan area rectangular or square block have lesser vertical surface area than complex shaped blocks. Higher ver- tical surface area results in large load spreading ability. It is obvious that the shaped blocks have better load distribution ability than the rectangular or square block. Although, earlier plate load test study by Knapton (1976) does not support this finding. But later on Shackel (1993 & 2000) by means of accelerated trafficking studies estab- lished that complex shaped block perform better than the rectangular or square one. The complex shaped blocks developed larger friction- al forces to transfer load to adjacent blocks. The shape of the block has significant influence on the performance of CBP under load.

Smaller size blocks have more numbers of joint per unit area than larger block. The blocks undergo rotation as well as translation on application of load. The tendency of rotation and translation of the smaller block is higher than larger block. Again, the tendency of translation is not distinct near edge of the pavement because of the edge restrain. It is conclusive that the pavement experiences larger deflection in case of smaller size block than the larger size. Larger block would improve the performance of the pavement within the size under study by Panda and Ghosh (2001).

The load spreading capability is a function of block thickness. As the block thickness increases the elastic deformation of the pavement reduces. Knapton (1996) reveals that the pavement performance is independent of block thickness. But researchers mainly Shackel (1980), Miura (1984) and Shackel et.al (1993) claimed dependency of elastic deformation on block thickness. Thus, with higher thick- ness of block, less magnitude of stress are transmitted to the under- neath layers. This is because of two reasons as stated below.

• Higher block thickness exhibits higher frictional resistance due to larger vertical surface area.

• The thrusting action between adjacent block at hinging point is more effective in case of thicker blocks (Panda and Ghosh

2001).

Deflection is less in case of thicker blocks. So load transfer is more efficient in thicker block because of the combined effect of higher frictional resistance and thrusting action. The response of pavement is highly influenced by the thickness of the block in CBP. The different thicknesses of blocks are used in different conditions and are mentioned in table1.

TABLE 1

THICKNESS OF BLOCK FOR DIFFERENT TYPE OF PAVEMENT

![]()

Block Thickness Type of Pavement

60 mm Light traffic such as, pedestri- ans, motor cars, cycles

80 mm Medium traffic

100-120 mm Heavily trafficked roads![]()

Thicker blocks are best suited where high volumes of turning move- ments are involved.

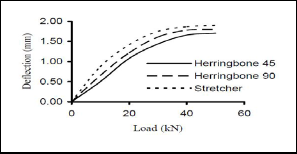

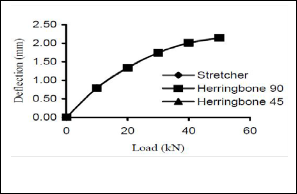

There are three types of basic laying patterns. They are stretcher bond, herringbone bond and basket weave bond pattern as shown in figure 2. Block laid in herringbone bond performs better under traffic loads. Plate load studies by Miura et al. (1984) and Shackel et al. (1993) revealed that when blocks laid in a herringbone bond exhibit- ed higher performance than blocks in a stretcher bond. This is pre- sented in Figure 3. The finding of Panda & Ghosh explained that the block pavement deflection is independent of laying patterns as shown in figure 4.The elastic deflection is same in all patterns they studied.

Fig.2. Laying patterns of CBP

Fig.3. Effect of laying Pattern (Shackle et al. 1993)

Fig.4 Effect of laying pattern reported by Panda (2002)

3.5 Block Strength

The blocks of the in-service CBP undergo compressive stresses due

to traffic loading. The bending stresses develop in blocks are negli- gible because of block size and its aspect ratio. As we all know that the concrete has many a times higher modulus of elasticity than the under laying layers. Hence the concrete blocks behave as rigid bod-

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 7, July-2013 784

ISSN 2229-5518

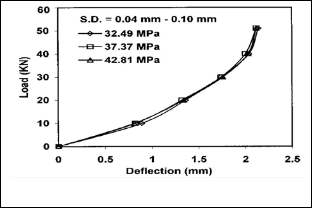

ies in CBP. Loads transfer to the adjacent blocks is by virtue of its

geometrical characteristics rather than strength of blocks. Shackel (1980), Panda and Ghosh (2002) concluded that the load associated performance of block pavements was essentially independent of compressive strength of the blocks. The effect of block strength on load-deflection behaviour of block pavement is shown in figure5.

Fig.5 Effect of block Strength

4 JOINTING AND BEDDING SAND

The recommended thickness of the bedding sand is widely varied from researcher to resear

cher. European practices (Eisenmenn and Leykuf 1988; Lilley and

Dowson 1988; Hurmann 1997) specify a bedding sand thickness of

50mm after compaction. Whereas compacted bedding sand thick-

ness of 20 to 30 mm is used in United States (Rada et al. 1990) and Australia (Shackel et al.1993). Simmons (1979) recommended a minimum compacted bedding sand depth of 40 mm to accommodate free movement of blocks under initial traffic. Mavin (1980) specified a compacted bedding sand depth of 30 ± 10 mm, keeping 10 mm tolerance on sub-base. The grading of bedding sand, Lilley and Dowson (1988) imposed a maximum limit on the percentage passing in 75, 150, and 300 μ sieves as 5, 15, and 50, respectively. Sharp and Simons (1980) required a sand with a maximum nominal size of 5 mm, a clay/silt content of less than 3 %, and not greater than 10 % retained on the 4.75 mm sieve. Single sized grain and/or spherical shaped grain sand are not recommended. Livneh et al. (1988) speci- fied a maximum particle size of 9.52 mm with a maximum limit of

10 % passing the 75 μ sieve. A typical grading of bedding and joint-

ing sand is presented table 2.

TABLE 2

Grading Requirement of Jointing Sand and Bedding Sand

Concrete blocks are placed very closely to each other in CBP. But there are always certain gaps in between blocks. These gaps are

Sieve Size![]()

Percent

Passing

Percent

Passing

filled up with sands and are known as jointing sand. Joint widths

ranging from 2 and 8 mm are often used, depending upon the shape

of blocks, laying pattern, aesthetic considerations, and application areas. Jointing sand plays a major role in promoting load transfer between blocks. The jointing sand is instrumental in spreading the load to larger areas in lower layers. Very few studies have been car- ried out on the width of joints and the quality of jointing sand for CBP. There are even fewer explanations of the behaviour of sand in the joints. For optimum load spreading by friction, it is necessary to provide uniform, narrow, and fully filled joints of widths between 2 and 4mm Shackelet.al. (1993), Hurman (1997). Knapton and O’Grady (1983) recommended joint widths between 0.5 and 5 mm for better pavement performance. As reported by Shackel, (1980), finer jointing sand having a maximum particle size of 1.18 mm and less than 20 % passing the 75 μ sieve has performed well. According to Knapton and O’Grady (1983), large joints require coarser sand and narrow joints require finer sand for good performance of CBP. In most of the pavements, the sand used for bedding course is also used in joint filling Lilley, (1980) and Hurmann (1997).

The British Standards 1973, passing the 2.36 mm sieve as the most effective for jointing sand. Panda and Ghosh (2001) studied the dila- tancy and shearing resistance of sand and recommended using coarse sand in joints of CBP. Livneh et al. (1988) specified a maximum particle size of 1.2 mm and 10 % passing 75 μ for jointing sand. The bedding sand is incorporated as a thin layer in between block layer and base course. There are two distinct purpose of bedding sand lay- er.

(BeddingSand) (Jointing Sand)

3/8 in. (9.5 mm) 100 - No. 4 (4.75 mm) 95 to 100 -

No. 8 (2.36 mm) 80 to 100 100

No.16 (1.18 mm) 50 to 85 90 – 100

No. 30 (0.600 mm) 25 to 60 60 – 90

No. 50 (0.300 mm) 10 to 30 30 – 60

No. 100 (0.150 mm) 5 to 15 15 – 30![]()

No. 200 (0.075 mm) 0 – 10 5 – 10

.

• To provide a smooth level running surface for placing the blocks

• . To absorbed considerable amount of stresses before trans- mitting the stresses to succeeding layers originated due to traffic load

4.1 Effect of Bedding Sand Thickness

Barber and Knapton (1980) reported the initial deformation occurred in the bedding sand layer due to truck traffic. Similar results have been reported by Seddon (1980). These investigations tend to con- firm the findings of the earlier Australian study by Shackle (1989)

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 7, July-2013 785

ISSN 2229-5518

which demonstrated that a reduction in the loose thickness of the bedding sand from 30 mm to 50 mm was beneficial to the defor- mation (rutting) behaviour of block pavements. Experience gained from more than twenty-five accelerated trafficking tests of prototype block pavements in South Africa has confirmed that there is no ne- cessity to employ bedding sand thickness greater than 30 mm in the loose (initial) condition, which yields a compacted typically close to

20 mm reported by Shackel and Lim (2003).

4.2 Effect of Sand Grading

Accelerated trafficking tests on block pavements had been carried out with the objective to determine the desirable properties of the bedding and jointing sands in South Africa. Pavements using Uni- Pave (Coro-lock) shaped block laid in herringbone bond had been constructed for the accelerated trafficking test. Loose thickness of 70 mm sand was laid over a rigid concrete base. After compaction, the sand layer thickness was reduced to 45 and 55 mm depending on the sand and type of grading. It was found that, under the action of 40 kN single wheel load a deformation up to 30 mm could occur in the sand layer within 10000 wheel passes. This clearly demonstrates the need to select the bedding sand with care. It was observed that pro- vided the grading of the sand falls within the limits recommended by Morrish (1980), a satisfactory level of performance cannot be achieved under traffic. Rutting deformations typically between 1.5 to

4 mm was noticed after 10000 wheels passes, where the same sand

has been used for both bedding and jointing the blocks. However, when finer sand having a maximum particle size less than 1.0 mm had been used as jointing sand; improvement in performance were observed with the maximum total deformations being less than 2 mm after 10000 load repetitions. Generally, for the bedding sand of coarser grain tend to yield better performance than fine sands and angular sands exhibit a marginally better performance than round sands. Unacceptable levels of performance have been observed where the proportion of finer material smaller than 75 μ in the sand exceeds about 15 percent. In sands with clay contents (20 to 30) %, substantial deformations up to 30 mm have been observed especially where the sands were wet reported by Interpave (2004).

4.3 Effect of Bedding Sand Moisture Content

Experience gained in accelerated trafficking studies in both Australia and South Africa has shown that adequate compaction of the bed- ding sand can be achieved with moisture contents ranging from 4 % to 8 %. The moisture content of 6 % represents a satisfactory target value. Seddon (1980) has suggested that, for optimum level of com- paction of the sand layer, the moisture content should be close to saturation. The effect of water content appears to have little influence under traffic if the grading of the sand complies with the limits. Us- ing Heavy Vehicle Simulator (HVS) trafficking were conducted when the sands are in saturated condition. No pumping was ob- served. When the bedding sand contain a significant proportion of clay, greater than 15%, the addition of water will substantially in- creases the deformation along with pumping. This is the reason use of sands containing plastic fines should be avoided in the bedding layer (Shackel 1998). Limited experimental evidence suggests that sands with plastic fines are nevertheless suitable for jointing sands. This would affect the mechanical properties of sand. At the time it will allow the ingress of water into the joints.

4.4 Width of Jointing Sand

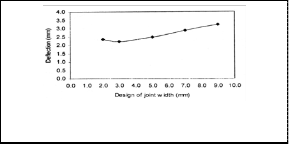

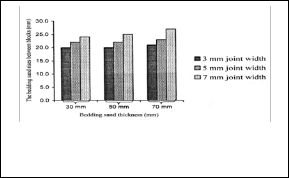

Mudiyono and Hasanan (2004) in their study used the same type of sand for bedding course with a 50 mm thickness. The response of pavement for design joint widths of 2 mm, 3 mm, 5 mm, 7 mm and 9 mm with same quality of sand as indicated in figure 6. The finding are distinct, as the joint width decreases, the deflection of the pave- ment also decreases.

Fig.6 Response of pavement deflection for design joint widths

The deflection of CBP decreases up to a certain point. Beyond this point, further decrease of joint width would lead increase in deflec- tion. There is an optimal joint width beyond which there is increase in deflection. The optimum joint widths for these experiments were found 3 mm. The interpretation is that higher the joint width, the normal stiffness of the joint will be lesser. This will lead to more rotations and translations of blocks. More deflection will occur under the same load for wider joints. It had happened because of some of the larger grain size particle than the joint width. They were unable to enter inside the joint gaps. This was observed during filling of sand in joints. A large amount of sand remained outside the joints on the block surface. The coarse grains of sand choke the top surface of joints and prevent movement of other fine grains in to joint. This situation had created some loose pockets or honeycombing inside the joint. The joint stiffness decreases and thus it reflects slightly higher deflections. The decrease in joint width would show improvement in pavement performance. The concept of optimum joint width was established with a series of static load tests by Mudiyono and Ha- sanan (2004).

4.5 Filling of Jointing Sand

It is a known fact that sands are very difficult to compact even with vibration. The effective compaction of bedding sand cannot be achieved for higher thickness of bedding sand.

During compaction the bedding sand rises through the joints to

small heights and wedges in between the blocks. The rise of sand through the design joints width of 3mm, 5mm and 7mm with varying thickness of bedding sand is shown in figure7.

Fig. 7 Comparision of Bedding Sand Rises in with vari- ous joint widths with bedding sand thickness, Knapton and O’Grady (1983)

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 7, July-2013 786

ISSN 2229-5518

The rise of sand increases with increase in thickness of bedding sand. The wedging of these sands absorbs the major part of applied vibra- tion energy and transfers less to the bedding sand below. As a result, the bedding sand is not fully compacted for higher thickness reported by Shackel (2003). Consequently, some compaction of bedding sand takes place under load and thus shows more deformation in the test pavements. Higher the bedding sand thickness, the more will be the deflection. The findings of this study are contradictory to those re- ported by Knapton and O’Grady (1983).

Knapton and O’Grady (1983) have found an increased bedding sand thickness produced a proportionate increase in load-carrying capaci- ty of pavement. The pavement response suggest for 50 mm thickness of bedding sand can be recommended to use in the field. But this depends on other factor, such as required level in sub-base tolerance and rise of bedding sand through the joints. Rise of bedding sand is essential to induce interlock. More importantly, there should be a sufficient depth of bedding sand for deflection of pavements under load.

The paved area must be restrained at its edges to prevent movement, either of the whole paved area or individual blocks. Edge restraints resist lateral movement, prevent rotation of the blocks under load and restrict loss of bedding sand material at the boundaries. Edge restraints should be laid at all boundaries of the block-paved area including where block paving abuts different flexible materials, such as bituminous bound material. They should be suitable for the rele- vant application and sufficiently strong to resist displacement if like- ly to be overrun by vehicles. It may be necessary to extend edge re- strains upto sub-base layers to support the blocks together with any base and hunching. Compaction of pavement layers near edge re- straints should be delayed until any concrete bed and hunching has gained sufficient strength to prevent movement of the edge restraint.

6 LOAD-DEFLECTIONS BEHAVIOUR

The load-deflection behavior is irrespective of block shape, size, strength, thickness, and laying pattern. It is seen that the pavement deflection increased in a nonlinear manner with increasing load. An interesting observation is that the rate of deflection decreases with increasing load (within the range of magnitude of load considered in this study). Increase in the load will result in the increases of rotation of individual blocks. This will lead to an increase in the translation of blocks and in turn an increase in the thrusting action between adja- cent blocks at hinging points (Panda and Ghosh 2001). As a result, the rate of deflection of the pavement decreases. It is established that the load distributing ability of a concrete block surface course in- creases with increasing load (within the range of magnitude of con- sidered in this study). The results obtained are similar to that estab- lished in earlier plate load tests by Knapton (1976), Clark (1978), and Miura et al. (1984).

7 EFFECTS OF LOAD REPETITION

results into deflection, which is not fully recovered. In other words, permanent residual deformations develop due to load repetition. Dur- ing loading, additional compaction of sand under blocks occurs, and some part of the energy is lost in that way. As a result, the recovery is not full. It is the relationship of deflection during loading and its recovery with number of load repetitions. It may be observed that both deflection and recovery decrease with an increase in number of load repetitions. After about 150 load repetitions, the deflection and recovery are nearly the same; i.e., the recovery is full. In other words, the pavement acquires a fully elastic property. This is due to the fact that the additional compaction of bedding sand gradually increases with increase in load repetition. After a certain number of repetitions, the compaction of the underlying layers reaches its full extent and no energy is lost during additional loadings. As a result, the deflection and recovery become the same (Panda and Ghosh,

2002). This means the CBP stiffen progressively.

In accelerated trafficking tests by Shackel (1980), the range of the number of load repetitions required to achieve fully elastic property varies from 5,000 to 20,000 depending upon the magnitude of load (24 – 70 kN). The bedding sand is compacted under the wheel load. Adjacent to the loading area, the surface of the pavement bulges out. Thus, the bedding sand loosens. Areas under the wheel track are subjected to alternate bulging and compression as the wheel moves. In this study, the load is applied at the same area and the bulging effect is nil, so it took only 150 numbers of load repetitions to achieve the fully elastic property.

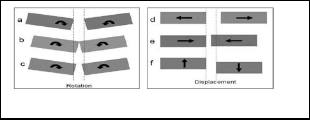

8 PAVER INTERLOCK

The interlock is defined as the inability of a block moving in isola- tion from its neighbors. The functioning of CBP largely depends on the degree of interlock of the blocks. There are three types of inter- locks as descried hereunder.

• Vertical interlock

• Rotational interlock

• Horizontal interlock

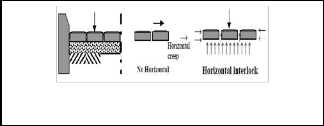

8.1 Vertical interlock

Vertical Interlock is the inability to move in vertical direction under load. Vertical interlock can be achieved by vibrating the blocks into well graded sand during construction. If the vertical interlock is not achieved the block would slide down vertically under load. At the same time it would exert high vertical stresses onto the underlying courses. The phenomenon of vertical interlock has been shown in figure 8. When bedding sands are compacted sand particles from bedding layer will raise upto a height of 25mm in the joint of block. The particles of sand wedge got surrounded around the perimeter of a block. So, the neighboring blocks are interlocked. The neighbor- ing block thus allowing a vertically loaded block to transfers it loads through shear as reported by shackle (1988).

Panda and Ghosh (2002) reported that the load deflection response is nonlinear. Moreover, initially the repeated loading and unloading

IJSER © 2013 http://www.ijser.org

Fig.8 Vertical Interlock

International Journal of Scientific & Engineering Research, Volume 4, Issue 7, July-2013 787

ISSN 2229-5518

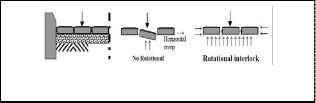

8.2 Rotational interlock

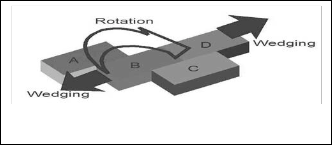

When a vertical load is asymmetrically applied to block, it hinges at the loading point, thus allowing the other side to move vertically. The rotational movement is only possible if the neighboring blocks are displaced laterally. The lateral movement of individual block is restricted by using edge restrained in CBP. Hence, rotational inter- lock is achieved which is shown in figure 9.

Fig.11 Rotation of paver B causing outward wedging of pavers

A and B

Fig.9 Rotational Interlock

Evidence also exists to support the theory that fine round sand brushed into the joints also helps to induces rotational interlock. A maximum particle size of 3 mm has been suggested for jointing sand.

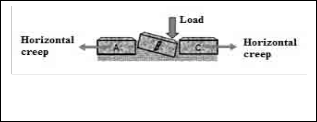

8.3 Horizontal interlock

The term creep is horizontal movement of blocks originated due to braking and acceleration force from traffic. These forces are instru- mental to cause breaking of blocks at the corner of one row, impart- ing local tensile stress into next row. Thus the horizontal movement of blocks takes place as indicated in figure 10 The creeping is more prevalent in case of rectangular block laid in stretcher bond. The rectangular block placed in herringbone pattern will reduce the creep movement considerably. Alternatively the shaped blocks eliminates the breakage of block to a large extend. Although the creeping can- not be eliminated totally in sever braking location but it affect can be control to a large extend to stop breakage of blocks. .

Fig.10 Horizontal Interlock

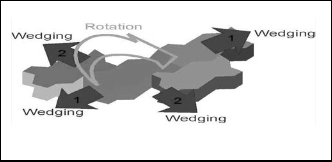

The wedging action illustrated in figure12 explains why it is com- monly observed that paving surfaces can push over inadequate edge restraints and make the reinstatement of trenches difficult or impos- sible unless the surrounding paving is restrained from creeping in- wards (Shackel, 1990). More importantly, it also explains why pav- ers act as a structural surfacing rather than merely providing a wear- ing course (Shackel, 1979, 1980 1990, 1997, 1999, 2000 and 2001). The factors which induce horizontal forces are paver shape and the laying pattern. The effects of paver shape can be understood by con- sidering the effects of paver rotation upon the wedging together of the pavers. The wedging and the rotation in rectangular pavers are illustrated schematically in figure11.

Fig.12 Effects of rotation on the wedging action of rectangular pavers

If paver B is subject to rotation about a horizontal axis through its midpoint then it is free to slide upon pavers A and C and will only push on pavers in line with the rotation such as paver D in Figure 12. Wedging therefore occurs only in that direction. By contrast, if the same rotation is applied to a shaped paver, then, as shown in figure

13, paver B cannot rotate without pushing pavers A and B away.

8.4 Mechanism of Paver Interlock

The block pavements which are well laid also exhibits rotation in blocks. The rotational movements are very small in relation to its neighbour. These are not imperceptible to the naked eyes in general and can be measured by profilometer. The rotations are usually less than 10°and are associated with surface displacements within 5 mm. These movement are appears to have little practical importance. However, because concrete pavers are manufactured more consistent dimensional tolerances than any other form of segmental paving they should be laid in such way so that the joints between the pavers are consistently narrow and relatively uniform in width. Due to such narrow and consistent joints, rotation of a paver soon results in it wedging against its neighbour. The wedging action caused by rota- tion of paver B around a horizontal axis leads to the development of horizontal forces within the paving to cause horizontal creep as sown in figure 11.

Fig.13 Effects of rotation on the wedging action of shaped pavers

Consequently wedging now develops in the two directions shown by arrows 1 and 2 even though the applied rotation remains unidirec- tional. This provides a simple explanation why shaped pavers have been reported to exhibit higher module and better in-service perfor- mance than rectangular pavers (Shackel, 1979, 1980, 1990 and

1997).

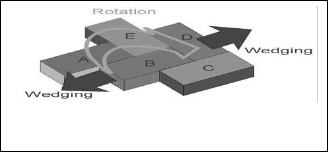

As discussed earlier elsewhere in this paper, CBP performs better when laid in herringbone bond patterns than laid in the stretcher bond patterns. Some explanation of this can be obtained by consider-

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 7, July-2013 788

ISSN 2229-5518

ing the effects of paver rotation. It may be seen that as in case of stretcher bond, rotation of paver B can still occur without horizontal- ly displacing pavers A and C as indicated in figure 14.

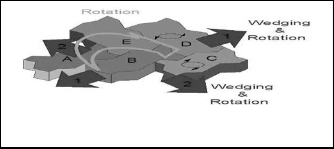

The movement of paver B about a horizontal axis will induce some

rotation of paver D around a vertical axis. This is in addition to de- veloping horizontal wedging as shown by the arrows. This will tend to increase the wedging action throughout the paved surface and provides some explanation why herringbone patterns perform better than stretcher bond. Some authorities have claimed that, once rec- tangular pavers are installed in herringbone pattern, they perform in a manner similar to shaped pavers. This is, however, contradicted by the results of both trafficking and laboratory load tests (Shackel,

1979, 1980, 1990). The most likely explanation for this is that, as shown in Figure 15, wedging in directions both along and across the axis of rotation remains the inevitable consequence of paver rotation irrespective of the laying pattern. Here the choice of herringbone bond adds additional wedging movements to the paving surface be- cause of the induced rotations of the pavers about vertical axes.

Fig.14 Effects of paver rotation on paving lay in herringbone bond

The explanations on the effects of paver shape and laying pattern given above are simple because paver rotations are seldom confined to movements about just a single axis. The effect of joint width or the nature of the joint filling material was not considered in the study. It is because, most pavers are fitted with spacer nibs the im- portance of the joint width and the joint filling material is minimal.

Fig.15 Effects of paver rotation on uni-pave shaped pavers lay in herringbone bond

However, it is usually found that the actual joint widths measured in pavements are bigger than the spacers. Moreover, tests of pavers fitted with spacer nibs have shown that the pavers develop little or no structural strength when the joints are left empty (Shackel et al,

1996). In other words, the joints are crucial to segmental pavement performance.

8.5 Role of Joints in Interlock

In describing and modeling the behavior of segmental paving many hypotheses have been put forwarded to explain the role of the joints.

There are 32 different movements are likely to occur at the joints in segmental paving as reported by Shackle (1992). These movements caused by rotations and linear displacements of the pavers. In prac- tice the movements shown as (a) and (d) in figure 16 are less likely to occur than the other movements because they imply net elongation of the pavement.

Fig.1

6 Movement of blocks at the joints

This will only occur when the pavement experiences rutting or heave i.e. some departure from the as-installed profile. In normal service the movements of pavers are likely to comprise combinations of both rotations and translations. The movement (c) in figure 16 represents the combined effects of movements (b) and (f) or (a) and (e). It is possible to measure rotations between adjacent pavers and to meas- ure lipping movement as shown figure 16 (f). However, horizontal displacements such as those illustrated in figure 16 (d) and (e) can only be measured directly. Nevertheless, some estimates of the strains in the jointing material can be obtained provided the stiffness of the jointing sand is known. The measured strains can then be used to estimate the stresses in the materials. The principal objective of this work was to estimate what magnitudes of force might be gener- ated within the joints.

9 PAVEMENT BEHAVIOUR

Investigators of block pavements have almost universally agreed that block pavements behave as a flexible pavement rather than rigid pavement. In flexible pavements the load applied to the pavement surface is distributed by a relatively thin wearing surface such as asphaltic concrete, and the under laying base and sub-base layer to the natural soil sub-grade. When the stresses on the sub-grade from the traffic loads are sufficiently large, the sub-grade will shear and displaced causing rutting in the sub-grade which appears as a surface rut. The classic failure of the flexible pavement is the rutting failure due to shear deformation in the sub-grade. All flexible design pro- cedures throughout the world consider this failure mode. Although other failure mode such as fatigue failure of asphaltic concrete sur- face or stabilized base layer is included but, a sub-grade shearing remains most crucial elements. The basic design concept can be summarized as

• Sufficient pavement thickness to protect the sub-grade.

• Quality base and sub-base materials to carry applied loads.

• Stable surface to provide wearing course for traffic.

• Compaction to provide strength and resist densification.

It is well established now that the paving block surface behaves as a coherent interacting structure rather than an assemblage of independ- ent rigid bodies loosely linked by sand filled joints. The ability of blocks to develop interaction and effectively distribute loads has been established. As with all flexible pavements the primary failure modes observed for block pavement is rutting, block breakage and spalling are a secondary problem usually with large ruts.

10 CONCLUSIONS

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 7, July-2013 789

ISSN 2229-5518

CBP differs from the other form of pavement in many ways. In the CBP, the wearing surface is made up of segmental paving blocks, bedding sand and jointed sand rather than a continuous paving sur- face. The edges are restrained by providing rigid kerbs sufficiently high enough to restrained movement of the blocks. In CBPs the blocks are the principal components which act as a load spreading member. The bedding provides necessary level surface for block paving. It also absorbed considerable amount of stresses before transmitting the stresses to succeeding layers originated due to traffic load. The jointing sands are the major components which initiate interlocking mechanism amongst the block and act as a single unit

and transfer the loads to the under-laying structure as well as

[8] B. Shackel, “The performance of interlocking block pavements under accelerated trafficking”, Proc. 1st Int. Conf. On Concrete Block Pav- ing, Newcastle-upon-Tyne, U.K., 113-120

[9] B. Shackel, D. O. Ooi Lim, “Mechanism of Paver Interlock” School of Civil and Environmental Engineering”, University of New South Wales, L & M Foundations, Singapore, ASCE

[10] B.Shackel, “The design of interlocking concrete block pavements for road traffic”, National Institute for Transport and Road Research, CSIR, South Africa, ASCE

[11] S.D. Barber and J. Knapton, “Structural design of block pavements for

st

amongst the blocks. The strength of the concrete block has less sig-

ports”, Proc. 1

International Conference on Concrete Block Paving”,

nificance in terms of load spreading ability but the thickness of the blocks is important in transferring the load. The intra-block load transfer is developed due to friction between the jointing sands and the block surface area. Hence with the increase of the thickness of the block the increment in the surface area results increased frictional force. The high resistance to deformation and durability of the CBP has made it a popular alternative to the pavement engineers. The loading of the pavement is essential to acquire elastic property of the pavement layers. When loads are applied through static plate load the elastic property yields at 150 to 200 repetitions. The elastic property under repeated load acquires at 5000 to 20000 repetition depending upon the magnitude of loads

The higher repetition is requires in case of trafficking conditions because of alternate bulging and compression of sand due to wheel movement. The interlock is the essentuial ptoperty of CBP.The her- ringbone pattern performs better than other pattern,

[1] J. Guidelines for the use of Interlocking Concrete Block Pavement, IRC: SP 63-2004, The Indian Road Congress, New Delhi 110011

[2] B.K. Panda and A.K. Ghosh, “Structural Behaviour of Concrete Block Paving. 1. Sand in Bed and Joins”, Journal of Transportation Engi- neering, Vol. 128, No. 2, March 2002, ASCE

[3] B.K. Panda and A.K. Ghosh, “Structural Behaviour of Concrete Block Paving. 2. Concrete Blocks”, Journal of Transportation Engineering, Vol. 128, No. 2, March 2002, ASCE

[4] B.K. Panda and A.K. Ghosh, “Source of Jointing Sand for Concrete

Block Pavement”, Journal of Transportation Engineering, Vol. 13, No.

3, December 1999, ASCE

[5] T. Muraleedharan, R.V.K. Rao. Prasant Kumar and P.K. Nanda, “Struc- tural Evaluation of Interlocking Concrete Block Pavement in the la- boratory and guidelines for design of ICBP for low volume roads”, CRRI, New Delhi-110020

[6] Clark., A.J., “Block Paving Research and development”, Concrete, Ju- ly 1978, 24-25

[7] Clark., A.J. , “Further investigations into the load spreading of con-

crete block paving”, Technical report. TR 545, U.K., Cement Concrete

Association. (1981)

Newcastle, U.K., pp. 141-49 (1980)

[12] S.D. Barber and J. Knapton, “An Experimental investigation of the be- haviour of a concrete block pavement with sand sub-bas”, Proc. Inst. Of Civil Eng., 69(2), 139-155 (1980)

[13] J. Knapton and S.D. Barber, “The design of concrete block roads”, Technical report 42.515, Cement and Concrete Association, Wexham Springs, U.K. (1976)

[14] J. Knapton, “Concrete Block Pavement Design in The U.K.”, Second International Conference on Concrete Block Paving, Delft, April (1984), London

[15] J. Kanpton and S.D. Barber, “UK research into concrete block pave- ment design”, University of Newcastle-upon-Tyne, UK, Cement Con- crete Association, UK

[16] J. Knapton and M. O’Grady, “The behaviour of a concrete block pavement”, Proc. Institute of Civil Engineers, London, 66 (1), 277-292

[17] R.S.Rollings, M. P. Rollongs, K. G. Sharp, “Evaluation of thickness

design concepts for block pavements”, Australian Road Research board, Australia, ASCE

[18] R.S. Rollings, U.S. Army Engineering Waterways Experiment Station, “Evaluation of block pavement design procedures”, Workshop on In- terlocking Concrete Pavements (1983

[19] L Mujaj, D.R. Smith, “Evaluation of Interlocking concrete pavements for airfields”, Interlocking Concrete Pavement Institute,

[20] G.R.Rada, D.R.Smith, “ Interlocking Concrete Pavement in North

America: A Performance Evaluation Study”, Segmental Concrete Sys- tem Association Sterling, Verginia, USA

[21] M. Huurman, “Resilient behaviour of concrete block pavement and the granular materials used in the sub-structure”, Pave Israel 96, Delft University of Technology, The Netherland.

IJSER © 2013 http://www.ijser.org