International Journal of Scientific & Engineering Research, Volume 5, Issue 6, June-2014 1063

ISSN 2229-5518

Non-conventional soil stabilization techniques The way forward to an aggregate free pavement And a Cost effective method of

Road Construction

Purnima Bajpai, Assistant Professor

ITM University, Gurgaon

Abstract—The decreasing availability or resources and the increasing cost of construction materials and uncertain economic climates has forced engineers to consider more economical methods for building roads. An obvious solution is to use locally available materials. As the road development projects are an integral part of a Country’s economic growth, costing almost 50% of the Country’s total investment in Infrastructure, a very careful evaluation of the alternatives is required which may proof to be beneficial to the economy.

However often, the alternate materials fall outside of required specifications. This situation becomes even more critical when an increasing demand for roads in underdeveloped rural areas. Likewise, there are increasing pressures on the mining, forestry and agricultural industries to minimize the production costs of their roads while delivering optimum performance and low maintenance costs. An economically feasible solution for achieving these objectives is the use of enzyme soil stabilization.

—————————— ——————————

Terrazyme is an effective and non-corrosive liquid enzyme that extensively enhances the properties of the soil used for con- struction of roads. It is a surfactant and its application assists in the expulsion of water from soils, and also helps in the lubrica- tion of soil particles and increases the compatibility of many kinds of soils. Its reaction of with many of these materials is particularly useful because of the ion-exchange capacity of clay minerals. TerraZyme can be used for various types of soil rang- ing from black cotton soils to hard murram soils. It can be used for all those types of soil which has a minimum 10% of clay par- ticles. TerraZyme is generally used for treatment of soils having Plasticity index in the range of 6 25 to 7.25. Soils after being treated with TerraZyme start behaving like a semi rigid pave- ment structure with much reduced permeability (1). Terrazyme is also designed to improve soil strength by increasing the den- sity of the initial compaction and facilitating the removal of pore water, which helps in minimizing the destructive impact of wa- ter under load.

The soil considered in these studies are mainly gravelly clay, silty clay, clayey sand, medium to fine sand-clay mixtures, silt and clay mix etc It has been proved that there is an increase in CBR value of more than 100% and Relative compaction by almost 100%. The clay minerals have a predominately positive ionic charge this causes clay minerals to have a strong attrac- tion for any cations present in the material (2). Cations are attracted to the positive clay minerals. Nominal temperatures will not remove them. This layer of water is known as the elec- trostatic diffused double layer system. The Large cations, such as sodium or water, cannot fit easily into these sites and get replaced. Small cations, on the other hand, fit firmly into these

vacated sites and cannot be removed. We thus have a situation in which the clay's negative charge is balanced and positive ions cannot be removed, thus rendering the clay inert to water. Terrazyme which is a cations-reactive synthetic compound forms a protective coating of an oily clay layer on the surfaces of soil and clay particles this reduces the ion mobility and ion exchange and thereby makes the material hydrophobic by eliminating the absorption of water. The result so obtained is a soil material which is much less sensitive to moisture, more workable and it can be easily compacted to a better particle- interlock state by simple equipment and traffic forces. Better particle interlocking means higher internal friction and thus an improved bearing capacity of the resultant soil. It also means greater density and less penetration of water in to the soil thus reducing the maintenance required. The soil mass is now a permanently stable, Water Repellent Road Surface similar to that of a rigid pavements made of Concrete but with better properties.

In India many trial roads have built with Terrazyme in order to construct a stabilized road structure , like in Kerala, Pondi- cherry,Trindivanam and Tamil Nadu and all of these projects this method has proved to be beneficial . Also many Munici- pality roads in many states have adopted the use of terrazyme, like the Public Works Department of Maharashtra revealed that the use of Terrazyme resulted in overall cost savings in the range of 18-26% (3).Also many roads in Bangalore have alao adopted this technique which have lead to a three time faster execution and also 25-30% cost saving as compared to conventional construction.

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 6, June-2014 1064

ISSN 2229-5518

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 6, June-2014 1065

ISSN 2229-5518

After carrying out a detailed study, analysis and calculation carried out on the use of terrazyme as a soil stabilizer, the au- thor would like to highlight the following findings

The above analysis shows that as compared to the conven- tional flexible or rigid design of pavements the per sqm cost of terrazyme stabilized pavements is less, leading to a cost saving of 45.4% as compared to flexible pavements and 55.9% as com- pared to that of rigid pavements.

Rapid construction speed and associated lower costs of ma- terials mean that the projects executed with Terrazyme deliver a much quicker return on investment as the time taken to con- struct conventional roads as the roads using TerraZyme be- comes functional much faster and the Road contract starts get- ting the returns at a much earlier date as compared to conven- tional techniques.. The use of Terrazyme can lower a road’s overall construction cost by 10% to 25%. AASHTO cost design models are used to show expected savings in comparison to standard project designs.

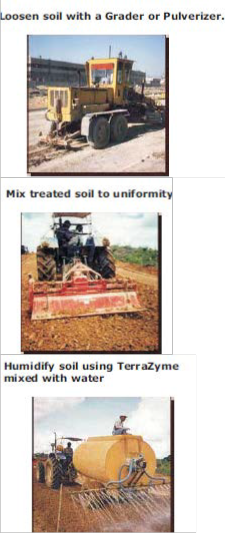

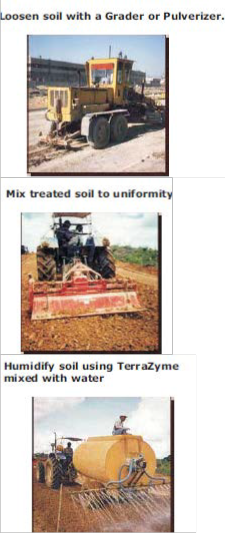

Terrazyme has an easy application procedure as already ex- plained and with the use of standard road construction equip- ments only an output of 3,000 square meters per day can be easily achieved.

Terrazyme soil stabilizer offers helps to increase layer

strengths and thickness with the use of local soils and within the

required cost of construction. The quality of road structures

built with Terrazyme can be far superior to those constructed

with conventional methods even when using local materials

that do not meet normal load building specifications. Where

local soil are sub-standard, and even with stabilization cannot

meet design specifications, Nature Plus engineers can assist in

soil blending options, which upon stabilization will achieve

desired specifications

Terrazyme increases the flexural strength of the road base or sub-base course in order to reduce movement from vehicle loading on surface pavements such as asphalt or concrete. The result is that fewer potholes and ruts are identified on unsur- faced roads and less cracking and loosening of surface tack coating than that for unstabilized conventional structures..

6. Increase in CBR% and Flexural strength

Terrazyme improves the load bearing capacity of soil. Roads

constructed using Terrazyme design concepts often reach a CBR

(California Bearing Ratio) value of 90% or more in the base or

sub-base layer as compared to 50% or less in an untreated struc-

ture. This improvement in flexural strength ensures a longer

economic life for flexible pavements placed on roads built with Terrazyme. The result is fewer potholes and ruts on unsurfaced roads and less cracking and surface loosening on roads with a surfaced coating

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 6, June-2014 1066

ISSN 2229-5518

[1] J Pawan nath g technical officer, nrrda, new delhi prof. b. p. chan- drashekar director (technical) madhavi vedula NRRDA, new Delhi “a critical review of innovative rural road construction techniques and their impacts”.

[2] U. ravi shankar*, harshakumarrai** & rameshamithanthayai. “bio- enzyme stabilized lateritic soil as a highway material†” Paper no. 553

[3] Brazetti, R. and Murphy, S.R. (2000),“ General Usage of Bio-Enzyme Stabilizers in Road Construction in Brazil”, 32nd Annual Meeting on Paving Brazil, October 2000.

[4] Andrew, R.Tolleson, Fadi, M. Shatnawi, Nicholos, E. Harman and Elahe Mahadavian (2003), “An Evaluation of Strength Change on Sub-grade Soils Stabilized with an Enzyme Catalyst Solution Using CBR and SSG Comparisons”, Geomatrics, Inc. Columbia, Sc 29210, USA, July 2003.

[5] IRC:SP:20-2002, “Rural Roads Manual”, The Indian Roads Congress, New Delhi.

[6] Isaac, K.P. Biju and Veeraragavan (2003), “Soil Stabilization Using Bio-Enzyme for Rural Roads” presented at the IRC Seminar “Inte- grated Development of Rural An Arterial Road Networks.

[7] TerraZyme - A replacement for metaling & Soling-Report by Avjeet

Agencies.

[8] Dr. Rubens Brazetti* and Dr. Sheldon R. Murphy** “Objective per- formance measurement of actual road sites treated with an organic soil stabilizer byTerrazyme”

[9] Skorseth, K., and A.A. Selim. Gravel Roads: Maintenance and Design Manual. South Dakota Local Transportation Assistance Program, Brookings, South Dakota; Federal Highway Administration, U.S. De-

partment of Transportation, Washington, D.C., 2000.

IJSER © 2014 http://www.ijser.org