International Journal of Scientific & Engineering Research, Volume 6, Issue 1, January-2015 952

ISSN 2229-5518

Implementation and Analysis of Fan Controlling

System on Programmable System on Chip

(PSoC)

Km. Mamta

Abstract— Increases in circuit density and clock speed in modern computer system have brought thermal issues into the spotlight of VLSI design. Lo- cal overheating in one part of a high-density circuit, such as a CPU or high-speed data routing circuit can cause a whole system to crash. Heat sinks and fan cooling for critical devices are the traditional methods of heat dissipation. A fan controller is an essential component of such high-quality thermal management systems. This paper gives an alternative solution to thermal management system by using PSoC technology, which reduce chip count, power consumption and design time of a product. We also use temperature sensor here for reducing noise according to ambient condition and PW M

technology to control a fan as it is more sufficient now a days for highly dense and battery operated systems.

Index Terms— Noise, Programmable System on Chip (PSoC), Pulse W idth Modulation (PW M), Thermal Management System,

1 INTRODUCTION

—————————— ——————————

ncreases in circuit density and clock speed in modern com- puter system have brought thermal issues into the spotlight

of VLSI design. Local overheating in one part of a high- density circuit, such as a CPU or high-speed data routing cir- cuit can cause a whole system to crash. Heat sinks and fan cooling for critical devices are the traditional methods of heat dissipation [1].

A fan controller is an essential component of such high-quality thermal management systems. Linear drive and PWM (Pulse-Width-Modulation) drive are two major classifi- cations of fan controllers. Linear drive provides a simple cir- cuit design by using a DAC (digital-analog converter), but it requires a tachometer output as a feedback mechanism. How- ever, PWM drive is mare attractive since it results in less pow- er consumption for the fan controller, with a linear correlation between the input controlling signal and the active duty cycle of the fan [1].Acoustic noise produced by fan is not only a nui- sance to the listener, but can also pose a significant health risk to humans. In the workplace in particular, acoustic noise emit- ted from electric motors has become a recognized health haz- ard, especially for persons who are exposed to noisy environ- ments for long periods of time [2]. There is main three factors which generate noise in a fan.

• The first one is fan speed.

• The second is the magnetic noise, generated by vi-

bration of the core due to the electromagnetic forc- es in the air-gap of the motor.

• The third is the noise generated by the bearings of fan motor

————————————————

Km. Mamta currently working as an Assistant Professor in electronics and communication department of Maharaja Agarsain Institute of Technology, Ghaziabad, India, E-mail: kmmamtasiddhu@gmail.com

Regulating fan speed according to the temperature inside an enclosure is the most effective method utilized to cool elec- tronic products. PWM is the preferred approach to regulating motor speed for three main reasons. First, PWM is energy effi- cient since it doesn't generate additional heat. Second, it im- proves the acoustics of the fan with high frequency driving signals. Finally, it provides thermal engineers with added op- erational speed bandwidth because the fan can run at either remarkably low or high speeds [3].

Presently, we give an alternative solution to thermal man- agement system by using PSoC as a controller, which reduce chip count, power consumption and design time of a product. We also use temperature sensor here for reducing noise ac- cording to ambient condition and PWM technology to control a fan as it is more sufficient now a days for highly dense and battery operated systems. Fan noise in a system is dependent on speed of fan, so it can be reduced by reducing fan speed. And when we reduce speed correspondingly power is also get reduced. Hence we take fan speed as a variable for analyzing fan controlling system using PSoC. We use an axial fan as for cooling approach, because compared to a centrifugal blower, axial fans offer higher volumetric flow rates (VFR’s) at rela- tively lower pressure drop conditions.

2 THEORY

2.1 Need for fan control

As modern PCs grow more powerful so do their requirements for electrical power. Computers convert most of this electrical power into heat generated by all major components. Some early generation PCs did not need active ventilation. Power supplies eventually needed forced cooling. The byproduct of increased heat generation is that the fan(s) need to move in-

IJSER © 2015 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 6, Issue 1, January-2015 953

ISSN 2229-5518

creasing amounts air and thus need to be more powerful. Since they must move more air through the same area of space, fans will naturally become noisier.

In fact, if one installs extra fans in a PC case, the noise lev-

els can reach 70 dB. Since fan noise increases with the fifth power of the fan [4] rotation speed, reducing rotations per minute (RPM) by a small amount potentially means a reduc- tion in fan noise. This must be done cautiously, as excessive reduction in speed may cause components to overheat and be damaged. If done properly fan noise can be drastically re- duced.

In addition to that if fan get stall then we can’t find fan

failure without monitoring or controlling a fan. Suppose a fan get stall, then it causes a component to get overheat and be damaged. That’s why the need of fan controlling comes into mind.

2.2 Pulse-Width Modulation

Pulse-width modulation (PWM) is a common method of controlling computer fans. A PWM-capable fan is usually connected to a 4-pin connector (Pin out: Ground, +12V, sense, control). The sense pin is used to relay the rotation speed of the fan and the control pin is an open-drain or open-collector output, which requires a pull-up to 5V or 3.3V in the fan. Un- like linear voltage regulation, where the fan voltage is propor- tional to the speed, the fan is driven with a constant supply voltage; the speed control is performed by the fan based on

the control signal. The control signal is a square wave oper-

ating at 25 KHz, with the duty cycle determining the fan

speed. Typically a fan can be driven between about 30% and

100% of the rated fan speed, using a signal with up to 100%

duty cycle. The exact speed behavior (linear, off until a thresh-

old value or a minimum speed until a threshold) at low con-

trol levels is manufacturer dependent [5].

2.3 Programmable System On Chip

PSoC stands for Programmable System on Chip made by Cy- press Semiconductor. Cypress also calls their PSoC devices mixed-signal arrays. PSoC is a true programmable embedded system-on-chip integrating configurable analog and digital peripheral functions, memory and a microcontroller on a sin- gle chip. A PSoC device consists of several sub systems on a single chip. The systems them self and the connections be- tween them may be configured to achieve a system on chip. Often times for the embedded designer, using a PSoC means that the bill of materials (BOM) for their product is reduced because the system that used to take several ICs can now be implemented in a single PSoC device. While BOM count re- ductions vary, with the right application reductions can be significant [6].

You can read detailed explanation of PSoC Technology on

Cypress Semiconductor Website [10]. There are three types of

architecture present in the market, which are as follows:

PSoC1 [7]

PSoC3 [8]

PSoC5 [9]

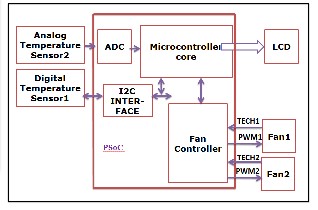

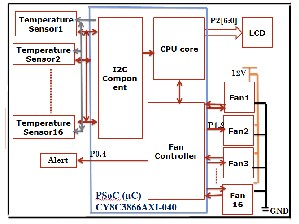

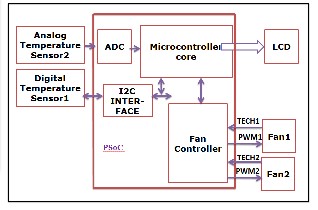

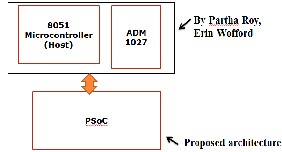

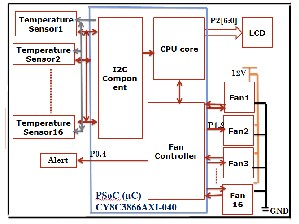

Block diagram of proposed fan controlling system using PSoC is shown in figure 1 and we are using PSoC 3 architec- ture for implementation.

Fig. 1. Block diagram of Fan controlling system on PSoC

3 METHODOLOGY

To implement this project research methodology is divided into two parts:-

• Software implementation

• Hardware implementation

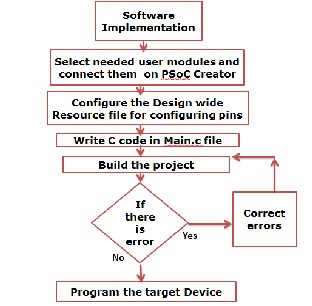

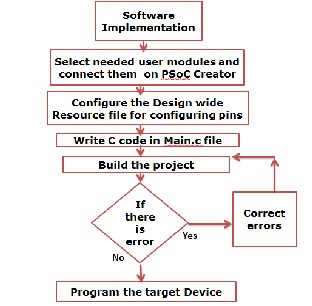

3.1 Software implementation

In software implementation first Select the needed user modules and connect them using wire tool in PSoC Creator Topdesign file.

Next step is to configure the Design wide Resource

file for pin configuration.

Next, Write a C code in Main.c file.

Then, Build the project.

If there is no error, then Program the target Device otherwise correct the errors, rebuild the project and program the device.

3.2 Hardware implementation

In hardware implementation first step is to connect

external Component to PSOC on DVK (Development kit) prototype area.

Second step is to connect input from prototype area to PSOC pins and output from PSOC pins to prototype area using jumper wires.

Next, Connect Miniprog3 to PSOC using 10-pin rib- bon cable and USB cable to PC.

Then, Connect power supply to DVK Board.

And Program the target device.

Reset the PSOC, see the results and analyze them.

4 HARDWARE IMPLEMENTATION

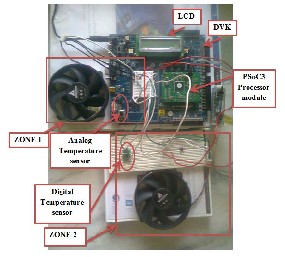

We are using two temperature sensors for two fans inde-

IJSER © 2015 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 6, Issue 1, January-2015 954

ISSN 2229-5518

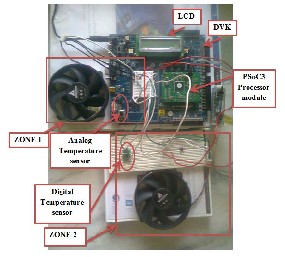

pendently; means digital temperature sensor is for fan2 and analog temperature sensor for fan1. An ADC is required in- built to PSOC to convert analog input into digital form from analog sensor and a I2C component is required to communi- cate with the I2C (TMP175) temperature sensor. We define two thermal zones corresponding to each fan. Zone2 has digi- tal temperature sensor and fan2 and Zone 1 has an analog temperature sensor and fan1. How temperature to speed is define for these Zones are shown in table 1.

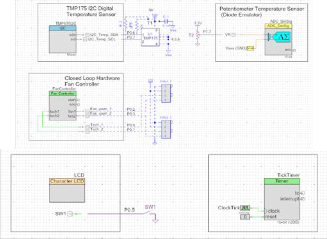

Fig. 3. Block diagram of Hardware implementation

Fig. 2. Block diagram of Software implementation

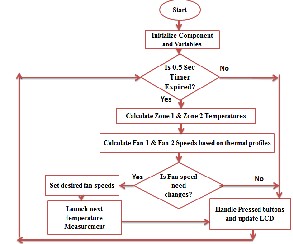

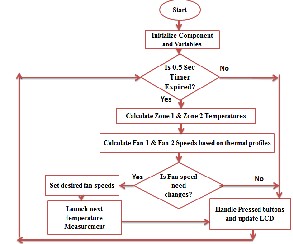

4.1 Working

The working of fan controlling system implemented on PSoC is explained via flow chart. The flow chart of the fan controlling system is shown in figure 4. In this first we initial- ize all the on chip components and variables then start a 500 ms timer and check for it. If it goes expire then calculate zone1 and zone2 temperature and corresponding fan speed from lookup tables otherwise do nothing. After calculating speed if need to change then send a command to fan controller to change it and also launch the next temperature measurement for next time otherwise do nothing. Finally check for switch whether a switch is pressed or not and according to that switch update the LCD for that particular zone.

Table 1: Temperature to speed lookup table for both zones

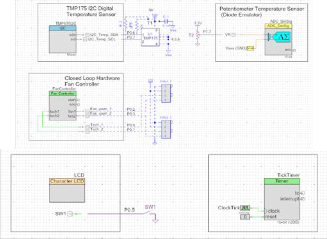

The circuit diagram for fan controlling system implement- ed on PSoC Creator Software is shown in figure 5. We connect pin 1 (SDA) and pin 2 (SCL) of TMP175 digital temperature senor to P0.6 and P0.7 respectively on DVK. As these lines are open drain type and need external pull ups so we connect re- sistance between pins and power supply. Pin 3 is an alert sig- nal, pin 4 (GND) is connected to ground. Pin 5,6,7 are the ad- dress lines and as we are using only 1 digital sensor so we connect these line to ground and address for this configuration of IC is 48H (for more detail please refer datasheet of TMP175) and pin 8 is connected to power supply. P0.0 and P0.1 pin of PSoC is connected to Tech_1 and Tech_2 signal of fan control- ler. P0.2 and P0.3 are connected to output of fancontroller. We are using a potentiometer on DVK as a sensor for testing pur- pose we can also replace this potentiometer to any other ana- log temperature sensor like diode, thermistor etc after that. And we connect potentiometer on P1.7 pin of PSoC. For changing the thermal zone we connect a switch on P0.5 pin of PSoC.

The first zone, Zone 1, combines temperature meas- urements from two temperature sensors (1 analog and 1 digi- tal). The analog sensor is simulated using a variable potenti- ometer to allow easy demonstration of fan control over a wide simulated temperature range without the need of an environ- mental chamber to cycle through temperatures. In Zone 1, the temperature senso1rs are combined using a weighted average where the potentiometer is given 90% weight and the digital I2C temperature sensor is given 10% weight. Adjust the poten- tiometer (R20 on the CY8CKIT-001 PSoC Development Kit) to vary the temperature value in the approximate range of 15 to

100 degrees C.

IJSER © 2015 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 6, Issue 1, January-2015 955

ISSN 2229-5518

Fig. 4. Flow chart of fan controlling system

Fig. 5. Circuit diagram of fan controlling system on PSoC3

In, Zone 2 Note that the temperature range is very narrow and close to room temperature. This is to allow for simple testing at room by just touching a temperature sensor with a warm finger to cause a fan speed change. In Zone 2, the temperature sensors are combined using a weighted average where the digital I2C temperature sensor is given approxi- mately 99% of the weight. And the potentiometer is given 1% weight. In this example TMP175 temperature reading will dominate the overall zone temperature calculation. The hard- ware set up for fan controlling system on PSoC is shown in figure 6. The LCD screen displays status information about fan controlling system across two screens. The user can cycle through the status screens by pressing SW1 on the CY8CKIT-

001 PSoC Development Kit. The screens are:

• Screen 1 - Zone 1 Summary: This screen displays the

current status of Zone 1. Line 1 displays the zone number, the current Composite zone temperature and the zone temperature calculation algorithm used. Line

2 displays the fan number, the desired fan speed for

Zone 1.

• Screen 2 - Zone 2 Summary: This screen displays the current status of Zone 2. Line 1 displays the zone number, the current Composite zone temperature and the zone temperature calculation algorithm used. Line

2 displays the fan number, the desired fan speed for

Zone 2.

The output observed in zone 1 by varying potentiometer on

DVK, the output for zone 1 at 24 and 36̊ C is shown in figure 7,

8 respectively. The output for zone 2 at 31̊ C is shown in figure

9.

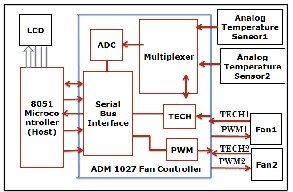

5 RESULTS AND DISCUSSION

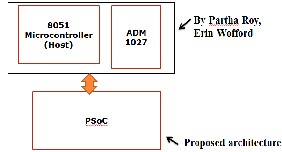

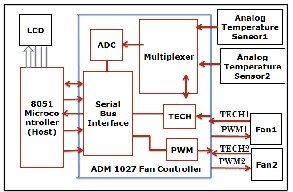

Fan controlling system By Partha Roy, Erin Wofford, Abe Arredondo for two fans is shown in figure 10. For this archi- tecture Partha use ADM1027 fan controller IC, this can control two fans with temperature sensors. ADM1027 IC can be con- nected to any host controller using I2C bus interface. It has inbuilt ADC into it and there is no need an external ADC chip. We can only connect diode as a temperature sensor to this IC.

Fig. 6. Hardware setup for fan controlling system on PSoC3

Fig. 7. Output for Zone 1 at 24̊ C

IJSER © 2015 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 6, Issue 1, January-2015 956

ISSN 2229-5518

Fan controlling system implemented on PSoC for two fans is shown in fig. 1. As PSoC has inbuilt ADC, I2C, and fan con- troller IC, then there is no need for external component and it reduces chip count on PCB board. For implementation of fan controlling system on PSoC we need temperature sensor and fan externally.

As we can see from fig. 1 and 10, two controllers IC is used by Partha Roy to make fan controller system with two fan, while in proposed architecture we replace both controller with a single IC. Hence chip count on board gets reduced.

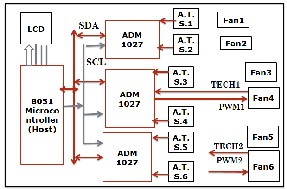

Fig. 11. Comparison of implemented fan controller on PSoC with base paper

As there is less chips on board, then power consumed by

component on board is also less. This feature can be more ex-

plained by a more complex system. Suppose for a telecommu-

nication server room we need to control 16 fans, then how the

system by Partha is used to control 16 fans is shown in figure

12.

Fig. 8. Output for Zone 1 at 36̊ C

Fig. 9. Output for Zone 2 at 31̊ C

Fig. 10. Block diagram of Fan controlling system By Partha Roy, Erin Wof- ford, Abe Arredondo for two fan

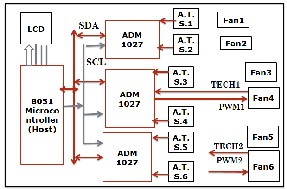

As ADM1027 is consist 3 address means we can connect 3

ADM1027 controller IC to a single host controller and 1

ADM1027 IC is responsible for controlling two fan with tem-

perature sensors, so maximum 6 fan can be controlled by sys-

tem shown in figure 12. To control 16 fans, we require 3 host

controllers and 8 fan controllers IC, So total 11 chips on PCB

board is required to control 16 fans by Partha architecture.

Fig. 12. Block diagram of Fan controlling system By Partha Roy, Erin Wof- ford, Abe Arredondo, ONLY CONTROL MAXIMUM 6 FAN W ITH 1 HOST CONTROLLER

But when we make this system using PSoC, the system is

look like as shown in figure 13. In PSoC, 1 fan controller com-

ponent is able to control 16 fans at a time, so we need 1 fan controller inbuilt and 16 temperature sensor and 16 fans ex- ternally. As we use temperature sensor TMP175, which has 27 addresses that means we can connect 27 TMP175 IC to a single

host controller via I2C bus interface. As 2 pins are require to connect a single fan, so to connect 16 fan 32 pins are sufficient and 7 pin for LCD and 2 pin for I2C bus interface, so total 42 pins are required by Fan controller on PSoC for 16 fan and there are 72 I/O pin are available.

If we compare two fan controller, then advantages of fan controller implemented on PSoC is given below-

In the previous architecture, we can only use diode as

a sensor, but using PSoC we have flexibility to choose

a temperature sensor according to our project re- quirement.

IJSER © 2015 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 6, Issue 1, January-2015 957

ISSN 2229-5518

Alert generated by fan controller can be directly con- nected to port pin in PSoC.

As fan controller IC is inbuilt in PSoC, than there is no need to implement I2C protocol in software, hence complexity in software is also get reduced.

If we comparing chip count except fan and sensors, than 11 IC’s are Required for Previous architecture for

16 fan to control, but using PSoC in place of these IC

only 1 IC is used.

Hence chip count get reduced, so power consumption and board size is also get reduced.

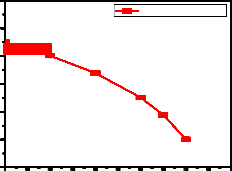

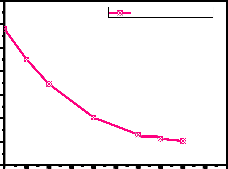

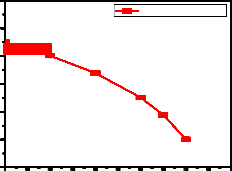

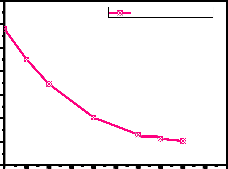

different speed as shown in table 2.

And when we plot these points on graph the graph is

look like as shown in figure 14. It is clearly shows in the graph

that by reducing speed by some amount we can reduce noise

of a fan, when fan is not needed to run at full speed.

Table 2: Speed to Noise reduction table

Fig. 13. Block diagram of Fan controlling system on PSoC with 16 Fan

Now how noise of a fan is reduced is explained below:- Suppose,

= Known Speed

= The new speed we are using for calculation

= Known Noise at

= New Noise calculated at new speed

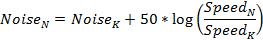

Calculating Noise at different speeds: The effect of speed on noise can best be seen through one of the fan laws: If we know the noise produce by a fan at maximum RPM than noise at new speed can be calculated by the following formula

(1) We are using a fan with 45 dBA noise at its maximum

(1) We are using a fan with 45 dBA noise at its maximum

speed (3800) and if we are able to reduce speed of a fan by

20% by using temperature sensor then around 5dBA noise will

get reduce from uncontrolled fan. The mathematical calcula-

tion is shown below-

= 45 + 50 * log (3040/3800)

= 45 + 50 *(-0.0969)

= 45 – 4.845

= 40.15 dBA

So noise gets reduced to 40.15 dBA from 45 dBA for

individual fan. Similarly we can calculate noise reduction at

60

Reduction in Noise

50

40

30

20

10

0

0 10 20 30 40 50 60 70 80 90 100

Reduction in Speed % (RPM)

Fig. 14. Reduction in noise

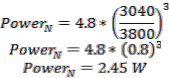

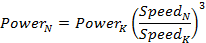

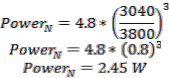

When speed gets reduce, how power consumed by the fan gets reduced is explained below: Suppose,

= Known Power at

= New Power calculated at new speed

Calculating Power Draw at different speeds: If we know

power consumed by a fan at its maximum RPM then how we

can calculate power at another speed is given by the following

formula:

(2)

(2)

We are using a fan with 4.8 Watt at its maximum speed (3800) and if we are able to reduce speed of a fan by

20% by using temperature sensor then around 2.35 Watt pow- er will get reduce from uncontrolled fan. The mathematical calculation is shown below-

Table 3: Speed to power reduction table

IJSER © 2015 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 6, Issue 1, January-2015 958

ISSN 2229-5518

modifying some firmware part. Here we successfully control the speed of brush less DC fan using temperature sensor and we show the effect of speed on noise and power, draw graph for various points. As a conclusion, Power Monitoring and Fan Control solutions implemented on PSoC simplify system design and deliver highest reliability for telecommunication, server and storage markets, where reliability is critical.

So power gets reduced to 2.45W from 4.8W for indi- vidual fan. Similarly we can calculate power reduction at dif- ferent speed as shown in table 3. And when we plot these points on graph the graph is look like as shown in figure 15. From the graph it is clearly shows that if we reduce speed of a fan linearly, then power consumed by the fan decay around exponentially.

Hence fan controlling system with temperature sen- sor is used where, system runs at critical condition, means if we know the temperature goes beyond acceptable limit then we can add one more task to the project that system will go to shut down mode after saving all the data. It is also useful where there is no need to run fan at full speed, so fan noise and power also get reduced. This also extends the operating life of the fan compared to systems that run all fans at full speed all of the time.

The size, shape, and pitch of the fan blades all con- tribute to the fan‘s capability to move air. Obviously, smaller fans will need to run at a higher speed than larger fans to move the same volume of air in a given time frame. Applica- tions that are space constrained and need smaller fans due to physical dimension limitations will generate significantly more acoustic noise. This is an unavoidable trade-off that needs to be made to meet system level needs.

6

Reduction in Power

5

4

3

2

1

0

-1

0 10 20 30 40 50 60 70 80 90 100

Reduction in Speed (% (RPM))

Fig. 15. Reduction in power to speed graph

ACKNOWLEDGMENT

Firstly, I want to mention here that this Research work has been conducted between the time periods from July, 2012 to May, 2013 at Lovely Professional University, Punjab, India. Because of some personal problems I was unable to publish my research work at that time. Secondly, With deep sense of gratitude, I express my thanks to my Guide, Mr. Mayank Gup- ta, Assistant professor, Electronics and Communication Engi- neering Department, Lovely Professional University, who has constantly been there to provide me technical support and for giving me the opportunity to complete my research work un- der his direction. I also thankful to university management and Dean of the department of Electronics and Communica- tion Engineering, Prof. Bhupender Verma , Lovely Profession- al University for giving me permission to commence this the- sis and to do necessary research work.

REFERENCES

[1] Herming Chiueh, Louis Luh, “A Novel Fully Integrated Fan Controller for Advanced Computer Systems”

[2] Nasrin Hashemi, Robin Lisner, Donald Grahame Holmes,” Acoustic Noise Reduction for an Inverter-Fed Three-Phase Induction Motor” IEEE, vol.3, 2004, pp. 2030 - 2035

[3] Abe Arredondo, Partha Roy, Erin Wofford, “Implementing PWM Fan Speed Control within a Computer Chassis Power Supply,” Twentieth Annual IEEE, Vol. 1, APEC 2005, pp.148 - 151.

[4] http://books.google.co.uk/books?id=UocszUe2WgC&lpg=PA341&ots=E MHJiQNH__&pg=PA341#v=onepage&q&f=false

[5] "4-Wire PWM Controlled Fans Specification". 2005-09. Retrieved 2011-

07-21.

[6] "Cypress Hits Half-Billion Mark in Shipments of PSoC Programmable

System-on-Chip Devices" 2009

[7] PSoC® 1: CY8C28 Family Datasheet [8] PSoC® 3: CY8C38 Family Datasheet [9] PSoC® 5: CY8C55 Family Datasheet

[10] Cypress Semiconductor Website: http://www.cypress.com

6 CONCLUSIONS

This work first explains about why we need a fan control sys- tem and then we describe steps to implement fan controlling system on PSoC. In this case, we control two fans inde- pendently using PSOC with temperature sensor, but we can modify this project to number of fan as we needed just by

IJSER © 2015 http://www.ijser.org