Figure 1: Hounsfield balanced impact testing apparatus used for measuring Impact strength.

International Journal of Scientific & Engineering Research, Volume 5, Issue 9, September-2014 951

ISSN 2229-5518

Impact strength of poly propylene fiber reinforced

PMMA

Merin Mathew, Kamalakanth Shenoy, Ravishankar K. S.

Abstract— PMMA is one of the most widely accepted biomaterials due to its acceptable advantageous but the limitations associated with these materials make them far from being ideal. So the present study is to achieve desirable impact strength by reinforcing PMMA with poly propylene fiber. Determination of impact strength of PMMA by varying the weight percentage of poly propylene fiber (2.5wt%, 5wt%,

10wt%), and by varying the aspect ratio (3mm/220μm, 6mm/220μm, 12mm/220μm) of poly propylene fiber. Specimens prepared using a

standard cylindrical mold of 8mm diameter and 45mm length. A total of 100 samples prepared (10 samples in each group) Polymer – monomer ratio 2.4:1 by Weight used to prepare samples. Impact strength tested using Hounsfield balanced impact testing apparatus. The micro structural analysis performed using SEM. Detailed statistical analysis done by one way ANOVA.Highest impact strength is obtained with 12mm long fiber reinforced in 10weight percentage concentration.

Index Terms—PMMA, impact strength, poly propylene fiber

—————————— ——————————

oly methyl methacrylate is one of the widely accepted bi- omaterials in the most emerging field of craniofacial re- construction and prosthetic dentistry. It has got its superi- ority over other materials due to its biocompatibility, chemical inertness, dimensional stability, low density, good transparen- cy, color stability, availability etc. Though it is tough, it may fail due to sudden impact forces [1]. The modern era of fiber reinforced PMMA resulted in the development of polymer composite having superior impact strength than the conven- tional PMMA. Fibers are incorporated to protect composite against sudden failure at the crack initiation in matrix. The tension transferred to the fibers until the ultimate strength of

fibers is reached [2].

Poly propylene fiber is an important member of family of syn-

thetic fibers. This has got excellent biocompatibility and chem-

ical resistance. It is strong under acids, bases, bleaching

agents, organic solvents and dyes. It possesses good mechani-

cal properties such as good resilience, elasticity, tensile

strength. The density of polypropylene fiber is very low

(0.91gm/cm3) in fact it is the lowest of all synthetic fibers.

Moreover it is economical too. All these make poly propylene

fiber to be reinforced with poly methyl methacrylate dental

biomaterial [3].

The aim of the study is to determine impact strength of PMMA material by varying the weight percentage of poly propylene fiber (2.5wt%, 5 wt%, 10 wt %) and to determine impact strength of PMMA material by varying the length/

————————————————

• Merin Mathew is cirrently Lecturer at Dept.of Dental materials mahe Institute of Dental Sciences & Hospital, Chalakkara, Mahe. merin.mathew.lect@gmail.com, +91 (0)490 2337765

• Dr. Kamalakanth Shenoy is currently HOD., Dept.of Prosthodontics, Yenepoya Dental College, Mangalore.

• Dr. Ravishankar K.S is currently ASST. Professor, Dept. of Metallurgical & Materials Engineering, National institute of Technology, Karnataka, Manga- lore.

thickness ratio of poly propylene fiber .(3mm/220 μm, 6mm/

220μm, 12mm/ 220μm)

Detailed submission guidelines can be found on the author

Materials: Cylindrical metallic die having 8mm diameter and

45mm length for the preparation of wax pattern, modeling wax, elastomeric impression material (addition silicone putty consistency), dental stone type ІІІ gypsum product, type ІІ gypsum product, poly propylene fibers.

3.1.1. Preparation of gypsum moulds to obtain the acrylic specimen

Die of 8mm diameter and 45mm length fabricated in stainless steel. Using elastomeric impression material, the impression of the die is taken, the modelling wax poured into the impression and the wax pattern obtained was invested in the dental flask in the conventional manner using dental stone and model plaster. After one hour the invested flask kept for dewaxing, then any waxy residue removed by washing the mould by hot water and then cleaned using soap solution, allowed to dry, thin layer of separating medium was applied in the mould space, allowed to dry. The mould was then ready to be used for the preparation of acrylic specimen.

3.1.2 Preparation of PMMA resin specimen:

a. Control group:

Control group test specimen made with conventional heat polymerized PMMA resin (DPI heat cure) polymer and mon- omer (2.4gm: 1ml) mixed and allowed to reach dough con- sistency. Dough was kneaded and then packed into the mould, flask was closed and a pressure of 1400 psi was given and bench cured for 30 minutes in a hydraulic press appa- ratus. Then the flask was clamped and transferred it into the water bath. Temperature of the water bath elevated slowly to

72 °c, and maintained for 90 minutes. Then the temperature of

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 9, September-2014 952

ISSN 2229-5518

the water bath elevated to 100°c and maintained for 60 minutes. After completion of polymerization cycle, the flask was allowed to cool in same water bath to room temperature, and the acrylic resin specimens were retrieved after deflask- ing. The specimen obtained were finished and polished in the conventional manner.[4]

Figure 1: Hounsfield balanced impact testing apparatus used for measuring Impact strength.

b. Reinforced group:

Poly propylene fibers of varying length and concentration was taken and impregnated in the measured monomer for 5 minutes, then the polymer powder was weighed and mixed with monomer and poly propylene fiber. The mix was then allowed to reach dough consistency and the dough was packed and a pressure of 1400 PSI was given and bench cured for 30 minutes in a hydraulic press apparatus. Then the flask was clamped and transferred it into the water bath. Tempera- ture of the water bath elevated slowly to 72 °c, and maintained for 90 minutes. Then the temperature of the water bath elevat- ed to 100°c and maintained for 60 minutes. After completion of polymerization cycle, the flask was allowed to cool in the same water bath to room temperature, and the acrylic resin specimens were retrieved after deflasking. Specimens ob- tained were finished and polished in the conventional manner.

3.1.3 Testing:

Impact strength testing:

Impact strength measured using Hounsfield balanced impact testing apparatus. (Figure 1) [5]. The specimen placed in the groove provided in the right hand side of the testing appa- ratus. Once after placing the specimen firmly in position, the oscillation was given to both the arms provided in the test apparatus. The energy absorbed by the material was taken as

the impact strength and it was directly observed from the scale attached to the apparatus (Figure 2) [5]. The values ob- tained were multiplied using a conversion factor to match it with Izod value. Table-1.

Figure 2. Scale for measuring Impact strength/

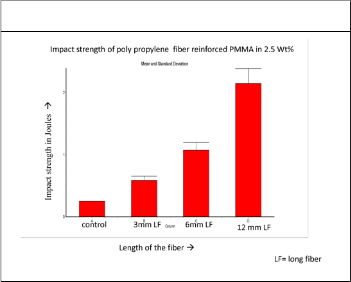

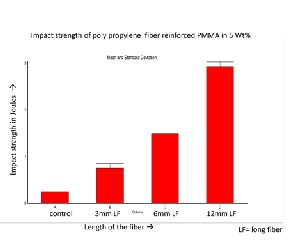

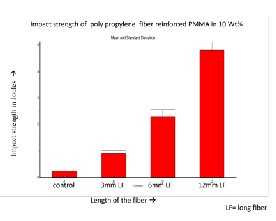

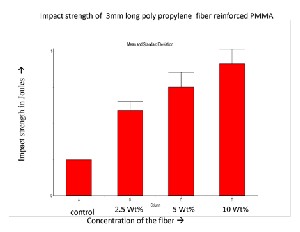

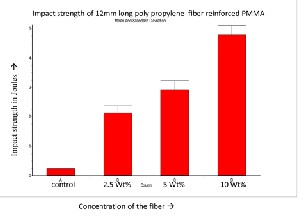

Higher impact strength obtained for 12mm fiber reinforced 10 wt %.(Table 1). Comparing same fibre weight with different fibre length, there was significant change in impact strength. (Figure 3, Figure 4 & Figure 5). Comparing different fibre weight with the same fibre length, there was significant change in impact strength. (Figure 8, Figure 9 & Figure 10).

The fracture of acrylic resin dentures as a result of being dropped is a common occurrence for denture wearers.[6] Figure 3: Impact strength of poly propylene reinforced PMMA in 2.5wt%

Materials with good impact strength absorb energy through the elastic action of the material and withstand the impact loading[7]. Preparation of polymer composite can decrease the

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 9, September-2014 953

ISSN 2229-5518

probability of fracture when impact force applied.

A polymer composite composed of primary continuous ma- trix material and secondary discontinuous dispersed materi- al.[8]

Figure 7: Impact strength of 6mm long poly propylene rein- forced PMMA. |

|

Figure 8: Impact strength of 12mm long poly propylene reinforced PMMA. |

The present study utilized the poly propylene fiber as rein- forcing agent as it is biocompatible and possess superior strength characteristics.[9]. Mechanical properties of the pol- ymer composites are superior to either of the individual com- ponents. When stress applied fibers reinforce the polymer ma- trix by distributing the increased load near the crack tip over a larger area increasing the zone of plastic deformation and thus the energy dissipated. To cause further propagation of crack, the fiber either should broken or pull out of the matrix. Both the phenomenon actually increases the strength of the material [10].

Brittle polymeric materials are often sensitive to stress con- centrations at sharp corners and cutouts so they perform poor- ly in notched impact test methods [11]. Hence in the present study the impact strength measured on unnotched test speci- mens using Hounsfield balanced impact testing machine.

Detailed statistical analysis performed using One-way

Analysis of Variance (ANOVA), Turkey-Kramer Multiple

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 9, September-2014 954

ISSN 2229-5518

Comparisons Test.

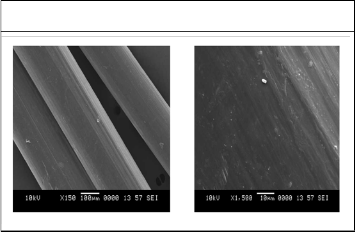

Figure 9: Morphology of the fiber surface was examined through scanning electron microscope.

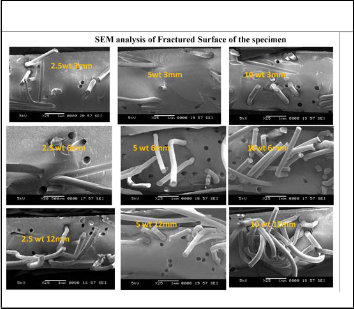

Fractured surface of the specimens observed under scanning electron microscope indicates that the major reason for failure could be due to fiber pullout or fiber breaking (Figure 10).

Figure 10: SEM Analysis of fractured surface of the speci- men

All reinforced groups exhibited higher impact strength value than the control indicates the load applied transferred from matrix material to the fiber and thereby the prepared polymer composite could perform better under impact loading than the unreinforced test specimens. Polymer composites often show a ductile- brittle fracture process [12]. Morphology of the fiber surface was examined through scanning electron microscope revealed that the irregularities in the fiber surface may in- crease the mechanical retention of the fiber with the matrix (Figure 9).![]()

Table 1: Impact strength of poly propylene fiber reinforced PMMA

3mm long poly propylene

6mm long poly propylene

12mm long poly propylene

fiber fiber fiber

![]()

1 0.25 0.5 0.75 1 1.25 1.5 2 2 3.125 4.375

2 0.25 0.63 0.88 1 1 1.5 2 2 3.125 5

3 0.25 0.63 0.75 0.88 1.25 1.5 2 2 3.125 5

4 0.25 0.5 0.88 0.88 1.25 1.5 2 2.5 3.125 4.375

5 0.25 0.5 0.75 0.75 1 1.5 2.5 2.5 2.5 5

6 0.25 0.63 0.63 1 1 1.5 2.5 2.5 2.5 5

7 0.25 0.63 0.63 1 1 1.5 2.5 2 3.125 4.375

8 0.25 0.63 0.75 0.75 1 1.5 2.5 2 3.125 5

9 0.25 0.63 0.88 1 1 1.5 2.5 2 3.125 5

![]()

10 0.25 0.63 0.63 0.88 1 1.5 2.5 2 2.5 5

Mean 0.25 0.591 0.753 0.914 1.075 1.5 2.3 2.15 2.9375 4.8125

![]()

SD 0 0.0627 0.102 0.1023 0.1207 0 0.2581 0.2415 0.3019 0.3019

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 9, September-2014 955

ISSN 2229-5518

Results suggest that polypropylene fiber reinforcement en- hances the impact strength of acrylic based denture materi- al. 10 wt % of 12mm long polypropylene fiber reinforced PMMA showed higher impact strength among the tested groups. However the impact strength not only depends on the fiber concentration and aspect ratio, but also controlled by several other factors like quality and type of fiber, orien- tation of fiber etc.

[1] Jagger DC, Harrison A, Jandt KD. The reinforcement of dentures. J Oral

Rehabil. 1999; 26(3): 185-94.

[2] L’uba Horbanova, Anna Ujhelyiova, Jozef Ryba, Jan Lokaj, Peter Mich-

lik. Properties of composite polypropylene fibers for technical applica-

tion. Acta Chimica Slovaca, 2010:3(2): 84 – 92.

[3] Paula E Silva E, Rosa EL, Barbosa SV. Tissue reactions of polypropylene

mesh used in maxillofacial trauma. Braz Dent J. 2001; 12(2):121–125.

[4] Sanjiv Rajender Dagar, Ashok J Pakhan, RU Thombare, Bhagwandas K

Motwani Evaluation of flexural strength and impact strength of heat polymerized PMMA denture base resin reinforced with glass and ny- lon fibers. Journal of Indian Prosthodontic Society 2008; 8(2): 98-104.

[5] Merin Mathew, Kamalakanth Shenoy, Ravishankar KS. Impact strength of e-glass reinforced PMMA. Journal of Evolution of Medical and Den- tal Sciences 2013; 2(32): 5971-5979.

[6] Amjad Rahamneh. Impact strength of acrylic resin denture base materi-

al after the addition of different fibres. Pakistan Oral & Dental Jour- nal.2009; 29(1):181 – 183.

[7] Vallittu, Narva. Impact Strength of a Modified Continuous Glass Fiber-

Poly (methyl Methacrylate), The International journal of Prosthodontics,

1997; 10 (2):142-148.

[8] Josmin P. Jose, Sant Kumar Malhotra, Sabu Thomas,Kuruvila Joseph, Koichi Gowda,M.S.Sreekala. Advances in polymer composites: macro and micro composites,state of the art, new challenges and opportuni- ties. Polymer composites Wiley VCH Verlag GMbH& Co.KGaA, 2012;

1(1):1-16.

[9] Tushar Krishnarao Mowade, Shankar Pandurang Dange, Mrunali Balkrushna Thakre, Vaibhav Deorao Kamble. Effect of fiber reinforce- ment on impact strength of heat polymerized polymethyl methacrylate denture base resin: in vitro study and SEM analysis. J Adv Prosthodont.

2012; 4(1): 30–36.

[10] McCarron, Andy. A Synergistic Approach to Modeling Crack Propaga- tion in Nanoreinforced Polymer Composites. (2008). Masters Theses

1896 - February 2014. Paper 107.

[11] Lloyd M. Robeson .Polymer blends: a comprehensive review. Page 341.

[12] M.S. Sham Prasad, C.S. Venkatesha, T. Jayaraju. Experimental Methods of Determining Fracture Toughness of Fiber Reinforced Polymer Com- posites under Various Loading Conditions. Journal of Minerals & Mate- rials Characterization & Engineering, 2011; 10(13): 1263-1275.

IJSER © 2014 http://www.ijser.org