International Journal of Scientific & Engineering Research, Volume 5, Issue 5, May-2014 325

ISSN 2229-5518

Improvement in Surface Properties of ABS Using

Carbon and Glass Fibre Reinforcements

Anish Raman.Ca, Veerappan K.Rb, Venkat Narayanan.Vc, Arun Raju.Cd

a, b, c. d Under Graduate Student,Department of Mechanical Engineering , Velammal Engineering College

Contact Email:vaibuthebaby@gmail.com

ABSTRACT- Acrylonitrile Butadiene Styrene (ABS) has several mechanical applications such as gears, bearings, washers etc. in these applications wear is the primary cause failure. Hence by reducing it we can increase the life. Here, ABS was reinforced with glass fibre and carbon fibre, at a mass ratio of 10% and 30%.Injection moulding was used for reinforcement and the coefficient of friction was estimated using pinon disk method. Other surface properties such as hardness, compression strength of the specimen were estimated. There was an observed increase in these properties with the increase in % wt. in reinforcement and carbon fibre reinforced ABS displayed greater improvement in surface properties compared to the glass fibre counterparts. ABS with 30% reinforced carbon fibre had the least coefficient of friction among all the samples.

Index Terms- ABS, Glass Fibre, Carbon Fibre, Hardness, W ear, Polymer

INTRODUCTION:

Wear is the primary reason for failure of plastic mechanical appliances polymer gears, polymer bearings etc. Priyanka Singh et al. investigated the tensile, torsional properties of ABS clay nano composites. For this the nano composites were produced by melt compounding method with different loading levels of nanoclay (Cloisite 30B)[2]. B.Ben et al. used the compression moulding to use graphite powder as a solid lubricant for ABS. Specimens were prepared with different mass ratios of ABS-graphite powder and co- efficient of friction was found for each sample. The coefficient of friction reduced with the addition of graphite powder [3]. L.Jiang

et al. improved the impact strength and modulus of ABS by reinforcing it with nanosized and micron-sized calcium carbonate by

melt compounding[4]. D.Mari et al reinforced ABS with CNT and achieved improvement in mechanical properties. Mechanical Spectroscopy was used for measuring in the research [5]. Tensile properties and fracture toughness of ABS blends with glass fibre was measured using Raman spectroscopy [6].ABS was reinforced with short carbon fibres (HCF) and improvement in tensile strength was obtained. The HCF was added at different weight ratios to ABS and adhesion properties were also studied. The SEM images revealed that there was an improvement in adhesion properties was obtained [7]. Juergen Schellenberg et al achieved increase in impact resistance with the addition of oligomers of acrylonitrile and styrene at different weight ratios [8]. Jinhu Chen et al. studied impact of alignment of CNTs on the erosive wear resistance in CNT composites of epoxy. Results showed that vertically aligned CNTs displayed superior wear properties compared to other samples.SEM images were used to corroborate that wear properties were dependent on alignment of CNTs[9]. B.Vijaya Ramnath et.al used glass fibre to laminate the top and the

bottom portion of the jute-abaca composite to provide greater surface finish and strength [10] .S.C. Sharma et al observed a decline in wear rate of ZA-27 alloys when they were reinforced with glass fibre. Pinon disk method was used to estimate the wear rate and Scanning Electron Microscope images of the surface after wear test was taken [11].The wear properties of PTFE was improved by reinforcing it with carbon fibre particles. Scanning Electron Microscope images were used to observe the wear in the surface [12]. Thomson et al. compared the tribological behaviour of epoxy resin reinforced with glass and carbon weave. Coefficient of friction, disc temperatures and wear rates were observed. The lowest coefficient of friction was obtained with carbon weave reinforcement [13].

INJECTION MOULDING:

Glass Fibre and Carbon Fibre is reinforced in virgin ABS using injection moulding techinic. Injection Moulding is a type of manufacturing process in which the materials are liquefied by heating in a barrel and then forced into the mould to obtain the required shape.

10%, 30% by weight of Carbon and Glass fibre was added virgin ABS. Simple Disc Mould was used for injection moulding purposes. Injection Moulding was done using .Five zonal temperatures were used in this injection moulding process. The zonal temperature was increased from rear end to the front end. Setting of zonal temperature is very important as a very low zonal

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 5, May-2014 326

ISSN 2229-5518

temperature allows air to mix with the plastic resulting in undesirable air bubbles and air cavity. A very high zonal temperature can also pose a problem as it results in plastic melting in the feed throat and loss of energy.

Table1: Zonal Temperatures

S.NO | TEMPERATURE |

1 | 2000C |

2 | 2150C |

3 | 2300C |

4 | 2450C |

5 | 2700C |

Rockwell Hardness:

Indentation hardness can be found using Rockwell hardness test .A glimpse of the tensile strength of the material can also be obtained as the ultimate tensile strength correlates linearly with Indentation hardness. For hardness testing, Rockwell Hardness testing Machine Mech.CS.RAB-1 with 2.5mm ball indenter was used for estimating the hardness of the specimens. Here a constant load of 150N was applied for testing these samples.

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 5, May-2014 327

ISSN 2229-5518

TABLE 2: ROCKWELL HARDNESS TESTS

S.NO | MATERIAL NAME | HARDNESS VALUE | MEAN HARDNESS VALUE |

1 | VIRGIN ABS | 97 | 103.7 |

1 | VIRGIN ABS | 1O5 | 103.7 |

1 | VIRGIN ABS | 109 | 103.7 |

2 | 10% GLASS REINFORCED ABS | 101 | 104.3 |

2 | 10% GLASS REINFORCED ABS | 105 | 104.3 |

2 | 10% GLASS REINFORCED ABS | 107 | 104.3 |

3 | 30% GLASS REINFORCED ABS | 106 | 109 |

3 | 30% GLASS REINFORCED ABS | 109 | 109 |

3 | 30% GLASS REINFORCED ABS | 112 | 109 |

4 | 10% CARBON REINFORCED ABS | 109 | 110.67 |

4 | 10% CARBON REINFORCED ABS | 112 | 110.67 |

4 | 10% CARBON REINFORCED ABS | 111 | 110.67 |

5 | 30% CARBON REINFORCED ABS | 110 | 111.33 |

5 | 30% CARBON REINFORCED ABS | 112 | 111.33 |

5 | 30% CARBON REINFORCED ABS | 112 | 111.33 |

COMPRESSIVE STRENGTH:

Compressive Strength the uni-axial compressive stress at which the complete failure of the material is achieved. Compression strength helps to determine the compressive stress the material can withstand in mechanical applications such as gears, bearings where compressive strength also determining the life .For this test a uniformly increasing compressive load is applied to the specimen and the point at which total failure of the material occurs is noted. Here compression testing machine of SUN LABTECH EQUIPMENT SL-CC-001 model is used.

TABLE 3:COMPRESSION HARDNESS

S.NO | LOAD(KN) | AREA(mm2) | COMPRESSION STRESS(M.pa) |

1 | 430 | 1934.24 | 222.30 |

2 | 460 | 1934.24 | 237.81 |

3 | 500 | 1934.24 | 258.50 |

4 | 510 | 1934.24 | 263.67 |

5 | 540 | 1934.24 | 279.20 |

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 5, May-2014 328

ISSN 2229-5518

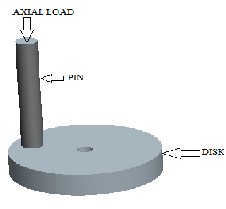

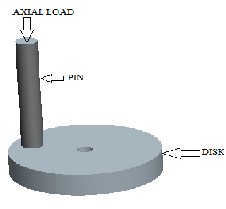

PINON DISC TESTS:

Pin-on- disc method is widely used wear testing applications. These tests were conducted at Anna University, Chennai. Load Cell attached to the pin-holder is used to find the frictional force.

Figure 1-:Diagram of Pinon Disk Testing

Table 4: Specification of the Pinon Disk Tester

S.NO | PARAMETER | SPECIFICATION |

1 | PIN | Dia.-:8mm, Length-: 50 |

2 | DISK | External Dia.-: 58mm, Internal Dia.- :6mm,Thickness-:10mm |

3 | WEAR TRACK RADIUS | 20mm |

4 | LOAD | 10N |

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 5, May-2014 329

ISSN 2229-5518

Table 5: Results of Pinon Disk

S.NO | MATERIAL | LOAD(N) | CO-EFFICIENT OF FRICTION |

1 2 3 4 5 | VIRGIN ABS 10% GLASS FIBRE REINFORCED ABS 30% GLASS FIBRE REINFORCED ABS 10% CARBON FIBRE REINFORCED ABS 30% CARBON FIBRE REINFORCED ABS | 10 | 0.365 0.36 0.30 0.28 0.25 |

SEM IMAGES:

The SEM images of ABS reinforced with 30% carbon fibre are shown in Figures 2 & 3

FIGURE 2 -:SEM image of ABS reinforced with 30% carbon fibre before wear test

FIGURE 2 -:SEM image of ABS reinforced with 30% carbon fibre before wear test

The SEM images helps us to see the extend of wear in the specimen by comparing it with the SEM image taken before wear test.

References:

[1] T.F.J. Quinn. The role of wear in the failure of common tribosystems, Original Research Article Wear, 100(1-3):399–436, 1984.

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 5, May-2014 330

ISSN 2229-5518

[2] Priyanka Singh, Anup K. Ghosh, Torsional, tensile and structural properties of acrylonitrile–butadiene–styrene clay nanocomposites, Materials & Design, Volume 55, March 2014, Pages 137–145

[3] B. Ben Difallaha, b, c, M. Kharrata, d, M. Dammaka, b, G. MonteilcMechanical and tribological response of ABS polymer matrix filled with graphite powder, Materials & Design Volume 34, February 2012, Pages 782–787

[4] L. Jiang, Y.C. Lam, K.C. Tam,T.H. Chua, G.W. Sim, L.S. Ang, Strengthening acrylonitrile-butadiene-styrene (ABS) with nano- sized and micron-sized calcium carbonate, Volume 46, Issue 1 Polymer

, 6 January 2005, Pages 243–252

[5] D. Mari,R. Schaller, Mechanical spectroscopy in carbon nanotube reinforced ABS, Materials Science and Engineering: A Volumes

521–522, 15 September 2009, Pages 255–25815th International Conference on Internal Friction and Mechanical Spectroscopy.

[6] A Loweb, S Kalyanasundaramb, P.-Y.B Jarc, V Otieno-Alegod, Chemical and mechanical properties of vinyl-ester/ABS blends , Polymer, Volume 43, Issue 16, July 2002, Pages 4503–4514

[7] J. Li, C.L. Cai, The carbon fiber surface treatment and addition of PA6 on tensile properties of ABS composites, Volume 11, Issue

1, January 2011, Pages 50–54, Current Applied Physics

[8] Juergen Schellenberg, Bernd Hamann ,Influence of styrene-acrylonitrile oligomers on the properties of ABS graft copolymers,

European Polymer Journal,Volume 29, Issue 5, May 1993,Pages 727–730

[9] Jinhu Chen, Ian M. HutchingsTong Deng, Tong Deng, Michael S.A. Badely, Krzysztof K.K. Koziol ,The effect of carbon

nanotube orientation on erosive wear resistance of CNT-epoxy based composites, Carbon, Volume 73, July 2014, Pages 421–431

[10] B. Vijaya Ramnath, S. Junaid Kokan, R. Niranjan Raja, R. Sathyanarayanan, C. Elanchezhian, A. Rajendra Prasad, V.M. Manickavasagam, Evaluation of mechanical properties of abaca–jute–glass fibre reinforced epoxy composite, Volume 51, October

2013, Pages 357–366,Materials & Design

[11] S.C Sharma, B.M Satish, B.M Girish, Rathnakar Kamath, Hiroshi Asanuma,Dry sliding wear of short glass fibre reinforced zinc–

aluminium composites, Tribology International,Volume 31, Issue 4, April 1998, Pages 183–188

[12] Shangguan Qian-qian, Cheng Xian-hua, On the friction and wear behavior of PTFE composite filled with rare earths treated

carbon fibers under oil-lubricated condition, Wear, Volume 260, Issues 11–12, 30 June 2006, Pages 1243–1247

[13]Thomas Ø. Larsen, Tom L. Andersen, Bent Thorning, Andy Horsewell, Martin E. Vigild,Comparison of friction and wear for an

epoxy resin reinforced by a glass or a carbon/aramid hybrid weave,Wear,Volume 262, Issues 7–8, 15 March 2007, Pages 1013–1020

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 5, May-2014

ISSN 2229-5518

331

IJSER © 2014

http /lwww ijser org