In this project we are showing root notches fixed to the blade and a shroud added to top of the blade to reduce the stress with a specific material. Applying different axial and centrifugal forces and loads on the blade to the maximum conditions.

International Journal of Scientific & Engineering Research volume 4, Issue 6 June 2013 562

ISSN 2229-5518

Mr. Leela Krishna Vegi

Department of Mechanical Engineering

Jawaharlal Nehru Technological University, Kakinada, Andhra Pradesh, INDIA E-mail ID: krishna.leeven@gmail.com

-------------------------------------------------------------------------------------------------------------------------------

Abstract— In high pressure turbine the temperature of the steam will be in a range of 5400c – 5600c and the flow of the fluid flow will be subsonic and supersonic. The pressure and temperature on the blade effects the surface of the blade, life cycle, deformation of the blade. In order to withstand blade at high pressure, temperatures, stresses and thermal loads the model of the blade is designed by introducing the cooling channels to the blade by supplying the cooling air through the rotor shaft which is extracted from the atmosphere and condenser to supply the coolant to the turbine blade. Using Grey cast iron material the blade profile can be able to withstand maximum pressure and temperatures and reduces the deformation levels. The aerodynamic profile, root notch and the shroud are designed using the CATIA v5 3D modeling software. The part is analysis with a material in ANSYS analysis software to observe the static structural, thermal and other required stresses at critical conditions in order to increase the life cycles and give better performance of the blade by using the Grey cast iron main high pressure steam turbine blade.

Keywords Impulse blade, steam turbine blade, cooling channels, high pressure turbine blades, fire-tree root notch, Design and

Modeling, Analysis.

1. INTRODUCTION

team turbine impulse blade is one of the most important part in the steam turbine rotor equipment system. Impulse blade is one of the high pressure withstanding blade which is placed in the starting stage of the turbine rotor arrangement in between the nozzle and the reaction blades. The steam produced from the boilers at high temperatures and pressures in a super saturated state and is supplied through the convergent and divergent nozzle to the starting stage of the steam turbine blade are called the Impulse blades. Its working principle is to convert the high pressure of the super saturated steam into higher velocity and rotates the shaft about 3000 r.p.m to 10,000 r.p.m which depends upon the capacity of thee turbine and the boiler.[Here the working fluid is the steam which strikes the turbine blade at a speed of supersonic flow].In order to withstand high pressure and thermal stresses the model of the blade should be in such a way that the blade profile is fixed with the shroud, cooling circuits and two different types of roots which are capable enough to withstand high

pressures and loads.

2. DESCRIPTION OF THE PROJECT

In this project we are showing root notches fixed to the blade and a shroud added to top of the blade to reduce the stress with a specific material. Applying different axial and centrifugal forces and loads on the blade to the maximum conditions.

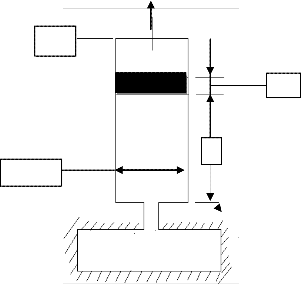

Fig. 1 High pressure stage of steam turbine

We can find the value of withstanding forces and temperatures’ using the ANSYS software shows the result in simulation view so that with the help of the diagram we can identify the deformation of the profile at any particular part and observe the physical, stresses, place of deformation. Using

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research volume 4, Issue 6 June 2013 563

ISSN 2229-5518

Gary cast iron for the analysis on the modeled steam turbine impulse blade on various like testing stress analysis, thermal analysis, static analysis, heat flux etc. with the better result of the best economical metal is chosen for the manufacturing for better performance of the blade. With the help of the theoretical calculations some of the unknown values are known for the better analysis and comparison calculated for the three different metals.

Fig. 2 Impulse Blade

In impulse there is no change in the pressure of the steam as it passes through the moving blades. There is change only in the velocity of the steam flow when the steam strikes the impulse blade through the nozzle inlet. An impulse turbine has fixed nozzles that orient the steam flow into high speed jets. These jets contain significant kinetic energy, which the rotor blades, shaped like buckets, convert into shaft rotation as the steam jet changes direction. A pressure drop occurs across only the stationary blades, with a net increase in steam velocity across the stage.

As the steam flows through the nozzle its pressure falls from inlet pressure to the exit pressure (atmospheric pressure, or more usually, the condenser vacuum). Due to this higher ratio of expansion of steam in the nozzle the steam leaves the nozzle with a very high velocity. The steam leaving the moving blades has a large portion of the maximum velocity of the steam when leaving the nozzle. The loss of energy due to this higher exit velocity is commonly called the "carry over velocity" or "leaving loss".

main feature of these turbines is that the heat drop per stage can be quite large, allowing for large blades and a smaller number of stages.

2.2 Blade stresses

The determination of blade stresses is a critical factor in the design of blades. The severest stresses are imposed by the centrifugal forces due to high rotative speeds. Bending stresses are also imposed by centrifugal forces, fluid-pressure differences and vibration. Centrifugal stresses are a function of the mass of material in the blade, blade length and speed. The component of centrifugal force acting radially outward exerts a tensile stress at the root. Sufficient cross sectional area must be provided in the blade at the root and a material capable of withstanding stress without fatigue must also be provided.

The centrifugal force on an element dr at a radius r

(fig) is given by

dF = (γa dr)ω2r

Where, γ = specific weight of blade material, kg/m3

a = blade cross-sectional area, m2; and

ω = angular velocity, rad/sec

Total centrifugal force exerted at the blade root is

Tip

dr

r

Width

Fig. 3 Centrifugal and bending forces on the turbine blade

In impulse turbines, high-velocity steam from fixed

𝒓𝟏

𝟐 𝛄 𝐚𝛚𝟐

𝟐 − 𝐫𝟐 ) [1]

nozzles impacts the blades, and this impulse drives the blades forward, causing the rotor to turn. The

Fc = ∫𝒓𝒓 𝜸𝒂𝒅𝒓 𝝎

𝐫 =

(𝐫

𝟐

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research volume 4, Issue 6 June 2013 564

ISSN 2229-5518

Where, rt = tip radius, and rr = root radius

Since the stress exerted at any section of the blading decreases radially, reaching a minimum

Fc =

![]()

𝛄𝐚𝛚𝟐

𝐀 =![]()

![]()

𝛄𝐚𝐀 [𝟐𝚷𝐍

]𝟐[2]

near the tip, a constant cross-sectional area is not

𝟐𝚷

𝟐𝚷

𝟔𝟎

𝟐 𝟐

required for strength. Hence, where the centrifugal

Where A = annular area = Π (𝒓𝒕 − 𝒓𝒓 )

The centrifugal or the tensile stress at the blade

root is thus

stresses are severe the blade is tapered by

decreasing both its thickness and width. Impulse blades are subject to bending from centrifugal stress and the tangential force exerted by the fluid.

Sc =

![]()

𝐅𝐜

![]()

= ɣ𝟐 𝑨( 𝑵

)𝟐[3]

Reaction blades have an additional bending stress

𝒂 𝟐𝟑.𝟗𝟒

If the blade is trapped, the mass of material is

reduced, thereby reducing the centrifugal stress.

due to large axial thrust because of the pressure

drop which occurs in the blades. All turbine blades may be subjected to bending because of vibration. The total stress at a given point on a turbine blade is found by adding the centrifugal stress at that point to the bending stress.

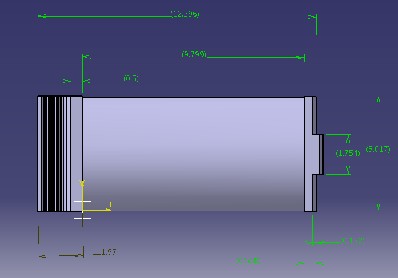

Fig. 4 Overall dimensions of the steam turbine impulse blade with a solid and Skelton view for cooling circuit blade profile

Blade profile design these are the following coordinates used for the generating the profile of the blade

Fig. 5 blade profile generated with the coordinates shown in the below

IJSER © 2013 http://www.ijser.org

Interna tional Jomnal of Scientif ic & Engineering Research volum e 4, Issue 6 June 2013 565

ISSN 2229-5518

These are the following coordinates used to gene rate the aerodynamic profile of the high pressure imp ulse blade on considering the inlet and outlet angles of the blade.

X-co ordin.ates Y- coordin.:!Jt<l s X-co ordinates Y- coordinates X-c:oordin.ates Y- coordinates

1. 1 | -0.00 2692 | 32. 0.273144 | 0.139633 | 64. 0.326314 | 0. 330709 |

2 . 0.970943 | 0.0 26901 | 33. 0.24978·6 | 0.127814 | 65. 0 .353526 | 0.335437 |

3. 0.945122 | 0.0'49222 | 34. 0 .226982 | 0.115549 | 66 . 0.38105 | 0.338513 |

4. 0.918544 | 0.069353 | 35. 0.204776 | 0.102977 | 67. 0.4{)8612 | 0.33976 |

5. 0.892009 | 0.087425 | 3fi. 0.183171 | 0.090 2 | 68. 0.4 357·64 | 0.339257 |

6. 0.865509 | 0.103765 | 37. 0.1621·6 | 0.077353 | 69. 0.462504 | 0. 337196 |

7. 0.839077 | 0.118555 | 38. 0.141683 | 0.064516 | 70. 0.488897 | 0. 333701 |

8 . 0.8128 | 0.1319 | 39. 0.121579 | 0.051742 | 71. 0.514!991 | 0.328.88 |

9. 0.786731 | 0.143892 | 40. 0.101678 | 0.039133 | 72. 0.540825 | 0.322787 |

10. 0.760918 | 0.154fi02 | 41. 0.081897 | 0.026911 | 73. 0 .56638 | 0.315487 |

11. 0.735401 | 0.16409fi | 42. 0 .0624!41 | 0.015613 | 74. 0.59168 | 0.30704 |

12. 0.710 216 | 0.1724!26 | 43. 0.044032 | 0.00621 | 75. 0.61 6742 | 0.297481 |

13. 0.685391 | 0.1796"W | 44!. 0.0 27925 | -0.000029 | 76. 0.641577 | 0.286854 |

14!. 0.'660955 | 0.185793 | 4!5. 0.01504 | -0.002453 | 77. 0.666206 | 0. 27519 |

15. 0.631693 | 0.190913 | 4<6 . 0 | 0 | 78. 0.690647 | 0 . 262516 |

16. 0.613332 | 0.195045 | 47. -0.010036 | 0.012399 | 79. 0.714918 | 0.248.853 |

17. 0.590177 | 0.1982 24 | 48 . -0.011,655 | 0.027498 | 80. 0.739039 | 0. 234221 |

18. 0.5'6748 | 0.200486 | 49. -0.009067 | 0.046818 | 8 1. 0 .763035 | 0 .218·631 |

19. 0.545245 | 0.20186 | 50. -0 .00 21601 | 0.068.828 | 82 . 0.78169 26 | 0.20 2087 |

20. 0.523478 | 0.20 2382 | 51. 0.006964 | 0.09199 | 83. 0.810735 | 0.184594 |

21. 0.502194 | 0.202073 | 52. 0.019094 | 0.115468 | 84!. 0.834486 | 0.166144 |

22. 0.48 B63 | 0.200959 | 53. 0.033584 | 0.138.8.89 | 85. 0.858201 | 0.146725 |

23. 0.4•61007 | 0.1'99074 | 54. 0.050395 | 0.162083 | 86. 0.8.81906 | 0.12r6308 |

24. 0.441159 | 0.196415 | 55. 0.069548 | 0.184897 | 81. 0 .905627 | 0.10485•6 |

25. 0.4!218·67 | 0.19 2996 | 56. 0.091031 | 0.20712 | 8B . 0.92938 | 0.082198 |

26. 0.4il 310.8 | 0.188781 | 57. 0.114818 | 0. 228533 | 89. 0 .95322 | 0 .058097 |

27. 0.3.84421 | 0.183688 | 58. 0 .140829 | 0 .24!8841 | 90. 0.9774U9 | 0.033022 |

28. 0.365441 | 0.177771 | 59. 0.168929 | 0.267763 | 91. 1 | 0.00 2638 |

29. 0.347214 | 0.171407 | 60. 0.198994 | 0.285033 | ||

30. 0. 321%5 | 0.1614!25 | 61. 0.230857 | 0.30038 | ||

31. 0.29704!1 | 0.150877 | 62 . 0.264357 | 0. 313567 | ||

63. 0. 298905 | 0. 324225 |

IJSER 2013

International Journal of Scientific & Engineering Research volume 4, Issue 6 June 2013 566

ISSN 2229-5518

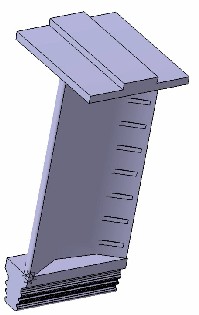

This is the design of the blade which is designed with the cooling channels provided to the blade profile with shroud on the top and the external fir tree type of root notch which is modeled in the Catia v5 modeling software.

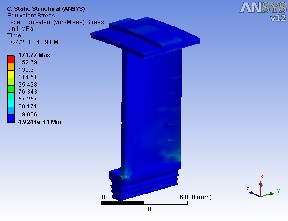

Fig. 7 Designed model imported in to Ansys

Fig. 7 Designed model imported in to Ansys

Fig. 6 Design of the impulse blade

There are eight rectangular sections of the cooling pass way is created from the vertical cooling circuit

which are projected from the bottom of the blade profile to the top of the shroud. A rectangular pocket is created at the bottom of the profile. A channel or the passage is created to the root notch in order to allow the cooling air through the cooling circuit to draw the heat or the hot gases passing through the blade.

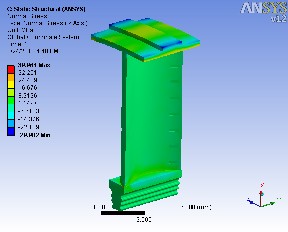

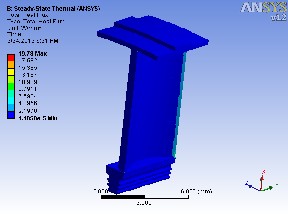

4. ANALYSIS OF THE TURBINE BLADE

Using the Ansys analysis software of the v12 version different pressure and thermal loads are applied on the blade profile to find the Equivalent stresses and normal stresses at a fixed position at different directional axis [X, Y, Z directions] so that we can observe the Maximum and minimum withstanding conditions of the blade profile on different materials and better performance and positive value of the material is considered like grey cast iron, ceramics and other alloy steels. ASTM Grade 40 [ISO grade 300, EN-JL1050] grey cast iron steel is used for the analysis of the blade.

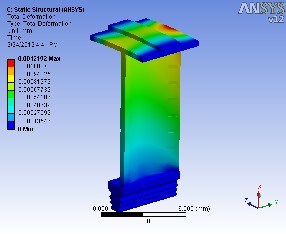

Fig. 8 Equivalent stress for Grey cast iron

Fig. 9 Total deformation for Grey cast iron

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research volume 4, Issue 6 June 2013 567

ISSN 2229-5518

4.1 Static Analysis of the Grey cast iron

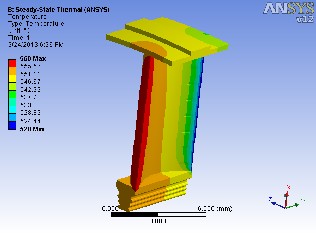

These are the inlet and outlet temperatures that are introduced into the turbine blade in the Ansys software for the thermal Analysis.

Table 2

Temperature parameters

Temperature at inlet | T = 5600c |

Temperature at outlet | T = 5200c |

Fig. 10 Boundary conditions for the blade

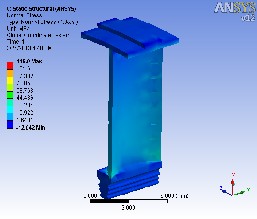

Fig. 11 Normal stresses on x – direction

Fig. 12 Normal stress on y – direction

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research volume 4, Issue 6 June 2013 568

ISSN 2229-5518

The centripetal force is the external force required to make a body follow a curved path. Any force (gravitational, electromagnetic, etc.) or combination of forces can act to provide a centripetal force. This force is directed inwards, towards the center of curvature of the path.

A simplified 2-D figure of the blades under discussion is shown in Figure.

Fig. 13 Normal stress on z - direction

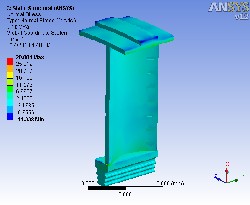

Fig. 14 Total heat flux

5. CALCULATIONS

TABLE NO. 3

Mechanical properties of Grey cast Iron

Fig. 15 Simplified blade dimensions

The general equation for centripetal force is:

F= mrω2 … (1)

Where, is the mass of the moving object is the distance of the object from the center of rotation (the radius of curvature) and mrω is the angular velocity of the object.

In the case under consideration, we need to account for the fact that the mass of the blade is distributed over its length and the radius of curvature also changes along the length of the blade.

Consider a small segment of mass δm, of length having width δr at a distance r from the centre. Then the equation for the centripetal force δF on this small segment is given by:

δF = δmω2r … (2)

In practice, a blade tapers in thickness towards its tip; but, for simplicity, assuming the blade to have a constant cross sectional area A (m2) and material density ρ (kg/m3), we can write:

δm = ρAδr

and equation (2) becomes

δF = ρAω2rδr

or formally,

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research volume 4, Issue 6 June 2013 569

ISSN 2229-5518

dF = ρAω2rdr … (3)

Let r1 be the radius of the rotor disc and be the distance between the centre of the rotor disc and tip of the blade. Then, integrating equation (3) along the total length of the blade, the total centripetal force acting on the blade is given by:

F = ρAω2∫𝒓𝟏 𝒓𝒅𝒓

Peripheral speed of rotor blade at its mid-span (blade![]()

πDN

velocity) Cbl =

60

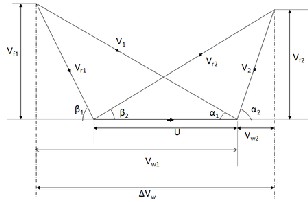

From the velocity triangles in figure

We get,

Whirl velocity Cw = Cw1+Cw0

So,

𝟐− 𝒓𝟐

= 790 m/sec![]()

F = ρAω2�𝒓𝟐

𝟐

𝟏� … (4)

We can convert the angular velocity from revolutions per minute (rpm) to radians per second using the following relationship:

Velocity of flow at entrance, Cf1 = 225 m/sec

Velocity of flow at exit, Cf2 = 180 m/sec![]()

𝒓𝒑𝒎×𝟐𝝅

ω =

𝟔𝟎

… (5)

Relative velocity at entrance, Cr1 = 450 m/sec

Knowing the values for the cross-sectional area, density, angular velocity and radii, we can then calculate the force on one blade. Once this force has been calculated, we can estimate the nominal stress σ on the blade root using the following relation:

𝑭

Now, Cr0 = K Cr1

= 0.8×450

= 360![]()

σ =

𝑨𝒓𝒐𝒐𝒕

… (6)

Relative velocity at exit Cr0 = 360 m/sec

Where, Aroot is the cross-sectional area of the blade root.

Absolute velocity of steam entering the blades,C1 = 600 m/s

Absolute flow angle (nozzle angle) α1 = 200

Blade velocity co-efficient, K = 0.8

Mass of steam flowing through the turbine, ms = 1000 kg/h

Fig. 16 the velocity triangles at inlet of first stage rotor blades were constructed as shown

Diameter of blade mid-span D = 1.0687 m, Design speed of turbine N = 3000 r.p.m,

Entrance angle of blade β2 = 290

Exit angle of blade β1 = 290

As the blades are symmetrical,

β2= β1 = 290

Absolute velocity of steam leaving the blades, C0 = 320 m/s

Tangential force, Pt = ms (Cw1 + Cw0)

= 1000 / (60×60) × (790)

Pt = 219.44 N

Axial force, Pa = ms (Cf1 - Cf0)

=1000/ (60×60) ×(45) Pa = 12.5 N

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research volume 4, Issue 6 June 2013 570

ISSN 2229-5518

Centrifugal force,

𝑟1

Fc = ∫𝑟2 𝛾𝑎 𝑑𝑟 𝜔2 𝑟 = γ a ω2/2 × (rt2 –rr2)

Where, rt = Tip radius, and rr = Root radius.

Fc = γ a ω2/2π (A)

= γ a A/2π (2πN/60)2

Where,

A = annular area = π (rt2 –rr2),

γ = density of material,

ω = angular velocity, rad/s

Now,

Density of material γ = 7850 kg/m3, Tip radius rt = 93.10 mm Root radius rr = 58 mm Blade cross-sectional area a = 2.791 mm2

Fc = 7850×10-9 × 2.71 × π [(93.10)2 – (58)2]/2π ×

[(2π×3000)/60]2

Fc = 5734 N

Now centre of gravity of blade in X, Y, Z directions are

Gx = 4.594 mm Gy = 2.134 mm Gz = 0.848 mm

5.5 Calculation of Factor of safety

yield point stress

1. Equation (1) for hard materials

2. Equation (2) for soft materials

5.6 Structural Analysis for Grey cast iron with cooling channels

![]()

ultimate stress

Factor of Safety [F.S] =

Design stress or working stress

![]()

240

=

171.77

F.S = 1.39

5.7 Result of the weight for Grey cast iron

Density of Grey cast iron = 7.4× 10−6 kg/mm3

Volume = 1788686.732 mm3

Weight = volume × density

= 1767552.586 ×7.4×10-6

= 13.08 kg

From the Literature Survey the various Input Parameters for the Analysis of impulse steam turbine blade has been collected.

By using Ansys software analysis (Structural,

Thermal) of the impulse steam turbine blade has been carried out successfully. We had done the analysis on considered different type materials from this grey cast iron is having the better performance and very much economical.

Static structure analysis is analyzed by applying different loads [tangential force, axial force and centrifugal force] at the boundary conditions. We get equivalent stress, normal stress in x, y, z directions and shear stress in xy, yz and zx planes. By comparing the stresses for different materials it is observed Grey cast iron is giving better performance to impulse steam turbine

F.S =

F.S =

Design stress or working stress

(Or)![]()

ultimate stress

Design stress or working stress

![]()

(1)

(2)

blade by introducing cooling circuit to the blade.

Thermal analysis is analyzed by applying inlet

and outlet temperatures at boundary conditions. We get total heat flux and directional heat flux x, y, z directions.

By using the Stresses obtained from the static

The above two formulas depends on the hardness of

materials:

structural Analysis the Factor of Safety is obtained.

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research volume 4, Issue 6 June 2013 571

ISSN 2229-5518

On calculated weight for three materials we found that the Grey cast iron is having the less weight so, that it can withstand stresses.

So, here we conclude that the impulse steam

turbine blade is observed to give a better performance by using the Grey cast iron material.

The life of the blade can be increased to 40 – 50

cycles. By using the density of 7000 kg/cm2.The weight of the blade of can be reduced and the work done by the blade will be increased.

a = Area of cross section

A = Blade cross-sectional area, m2; and

Aroot = Cross-sectional area of the blade root

Fc = Total centrifugal force

F.S = Factor of Safety

Gx = Centre of gravity on x- direction Gy = Centre of gravity on y- direction Gz = Centre of gravity on z- direction N = Number of stages

Pi = Pressure of steam at inlet

Po = Pressure of steam at outlet Vi = Velocity of steam at inlet Vos = Velocity of steam at outlet Va = Absolute velocity of steam Vr = Relative velocity of steam Vb = Blade velocity

θ = Nozzle angle

ø = Blade entrance angle

γ = Blade exit angle

δ = fluid exit angle

γ = specific weight of blade material, kg/m3

ω = angular velocity, rad/sec

rt = tip radius

rr = root radius

Sc = centrifugal or the tensile stress at the blade root

δm = small segment of mass

δr = distance r from the centre

ρ = material density, (kg/m3)

γ = density of material

The author is very much grateful to mechanical Engineering department, JNTU Kakinada, for giving some of the valuable suggestions for the design and analysis of the project with a proper guidance for completion of the project.

A text book of THERMAL ENGINEERING, 8TH edition by R.K Rajput, on the topic steam turbine from page no. 828 – 916, chapter – 19

A text book of Power plant engineering, 4th edition by R.K Rajput, on the topic steam power plant from topics 3.18 steam nozzles from page no. 198 – 205, 3.19 steam turbines from page no.

211 – 238.

Coupled CFD and thermal steady state analysis of steam turbine secondary flow path, leonid Moroz, Softlnway Inc., alexander tarasov

Stress Analysis of impulse turbine blades ,

Thacker, H.B. Khaleeq, F. Hourigan and J. Jarvis,

University of Limerick

David Gordon Wilson; 1991 "The Design of

High-Efficiency Turbo machinery and Gas Turbines", pages 487-492, published by the MIT Press, Cambridge, Massachusetts, 1984, 5th printing

1991

Turbine and its Auxiliaries, TOSHIBA

Whole Configuration Effect on Turbine Blade

Cooling, A.Hasapour, M.Farhadi and H.R

Ashorynejad.

Forces on large steam turbine blades by RWE n

power from UK mechanical and electrical engineering power industry. Pages from 1 -5.

http://encyclopedia2.thefreedictionary.com

IJSER © 2013 http://www.ijser.org