International Journal of Scientific & Engineering Research, Volume 3, Issue 10, October-2012 1

ISSN 2229-5518

Experimental study of effect of ignition timing and compression ratio on NOx emission of LPG fuelled engine

S. M. Lawankar, Dr L. P. Dhamande , Dr S. S. Khandare

Abstract - Alternative fuels like LPG, CNG, hydrogen etc has emerged as a solution to depleting crude oil resources as well as to the deteriorating urban air quality problem. As a gaseous fuel, LPG have already been established in terms of low emissions of carbon monoxide, hydrocarbon. Some parameter like compression ratio and ignition timing also affect exhaust emission. The present work is carried out to study the effect of compression ration and ignition timing on NOx from LPG fuelled SI engine. A single cylinder, 4-stroke, water- cooled, LPG fuelled SI engine was used; an arrangement was made to vary compression ratio and ignition timing. The results obtained show that the engine running on an LPG fuel system found to have about 15% to

35 % more NOx emission as compared to gasoline fuelled system. It was further observed that the NOx also affected by ignition timing. Retarding ignition timing NOx decreases by 12%. Advancing the ignition timing up to certain degree BTDC increases NOx and further advancement decreases the NOx.

Key words- Liquefied petroleum gas, compression ratio, speed, ignition timing, NOx, BTDC

1INTRODUCTION

Oil reserve all over the world is depleting at an alarming rate. In addition, the deteriorating quality of air we breathe is becoming another great public concern. Emissions of sulfur dioxide, hydrocarbons, carbon monoxide, nitrogen oxides, lead, etc. have encouraged the researches to find ways to reduce these emissions because of their impact on human health and ecological imbalance. Various alternative fuels suited for spark ignition (SI) engines are synthetic gasoline, alcohols, and gaseous fuels according to the studies conducted by Thring (1983) and Prausnitz et al., (1987). Gaseous fuels in general are promising alternative fuels due to their low cost, high octane number, high calorific values, and lower polluting exhaust emissions (Badr et al., 1989; Richard Stone, 1989; Beer, 2002). During the last decade, gaseous fuels such as liquefied natural gas (LNG) and liquefied petroleum gas (LPG) have been widely used in commercial vehicles, and promising results have been obtained in terms of the fuel economy and exhaust emissions. India is one of the countries seriously affected by pollution mainly caused by the exhaust emission from automobile. Realizing this problem and sensing the alarming rate of increase in pollutants in atmosphere, the Government of India has taken an important and encouraging step towards the reduction of atmospheric pollution by directing its attention towards the use of LPG as an automobile fuel. As mention above several researchers have worked with LPG as alternative fuel and a number of suggestion were put forward by them to improve engine performance. But on Indian road it was found that, the vehicles which run on LPG have lower

compression ratio ie 8:1& 9:1 which may not give satisfactory performance as far as properties of LPG are concerned. So, there is need carry out detailed experimental investigations of a LPG fuelled SI engine for a

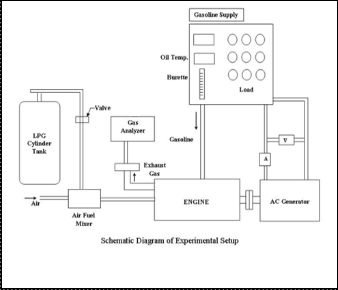

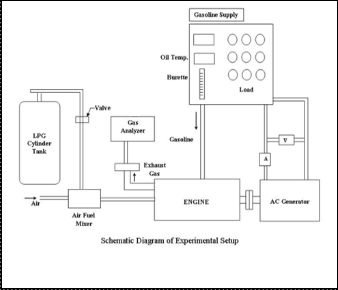

used in the study was a single cylinder, water cooled

,four-stroke spark ignition naturally aspirated engine with

a maximum rated power output of 2 kW at 1500 rev/min. An arrangement was made to vary compression

ratio and ignition timing. The detailed specifications of the

IJSER © 2012 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 3, Issue 10, October-2012 2

ISSN 2229-5518

engine are listed in Table. The apparatus used in the experiment involve a load bank, digital power meter, manometer, digital Thermocouple, a non contact type digital tachometer and direct current (DC) dynamometer and AVL Di-Gas 5-gas analyzer. Load Bank-The load bank consists of electrical bulbs, each bulb consumes 200W of power and is controlled by a switch. An electrical power load circuit is attached to the engine control panel to provide the engine with output loads used to power the electric bulbs. Digital Power Meter-The present test system is able to investigate the engine performance using different values of engine loads by switching the desired number of electric bulbs. The value of electric power, which was consumed by the electric bulbs, is measured by a digital power meter. Digital Thermocouple- A digital thermocouple is used to measure the body temperature and the exhaust temperature of the engine accurately during the experiment when running the engine using LPG and gasoline.

Table. Test Engine Specifications

which gives higher NOx. The NOx formation found to higher in LPG fuelled engine, this may be a result of high temperature which is due its slightly superior heating value and high burning speed and high oxygen concentration. It also lack in charge cooling effect

900

800

700

600

500

400

300

200

100

0

0 0.5 1 1.5 2

load

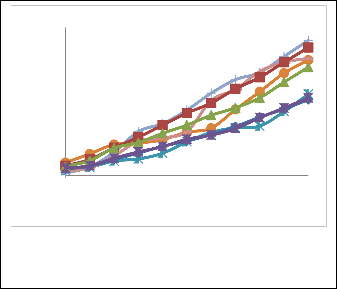

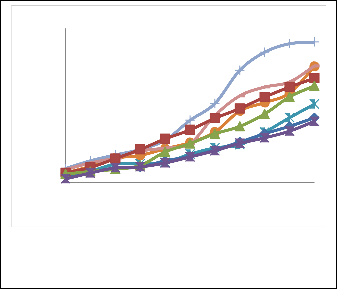

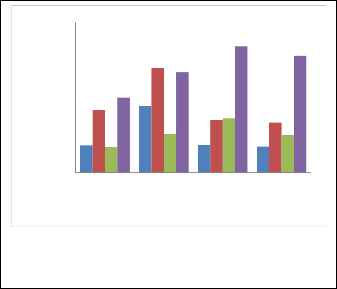

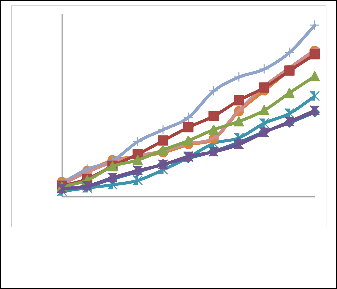

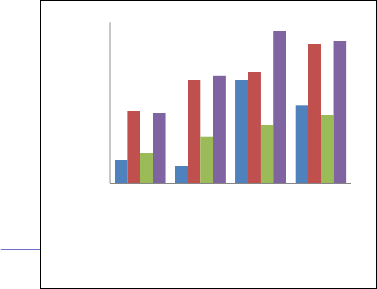

Fig1 Variation of NOx with respect to load at CR 9 and at ignition timing 10◦BTDC, 20◦BTDC, 30◦BTDC, 40◦BTDC for LPG and gasoline

1000

800

600

Gas Analyzer – AVL DIGAS 444 TYPE EMISSION ANALYZER was used to measure exhaust gas emission. The analyzer has the capability of sampling various exhaust products such as hydrocarbon (HC), carbon monoxide (CO), and carbon dioxide (CO2) with the option of oxygen (O2), oxides of nitrogen (NOX) and air- fuel ratio(λ).The weighing machine of capacity 30 kg with

400

200

0

0 0.5

lo1ad

1.5 2

least count 2 gram and glass burette respectively were used

to measure fuel supplied .Experimentation was first carried

out at constant rpm (1500) and varying load from 0 to 2 kW

in step of 200W on the gasoline fuel system and then

switched to LPG. The data was collected for NOx and

exhaust gas temperature. Procedure was repeated for compression ratio 9, 10, 11 and 12 and various ignition

timing 10°, 20°, 30°, and 40° BTDC.

3 RESULT AND DISCUSSION

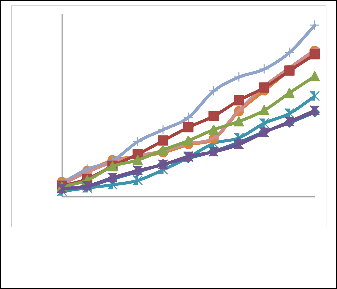

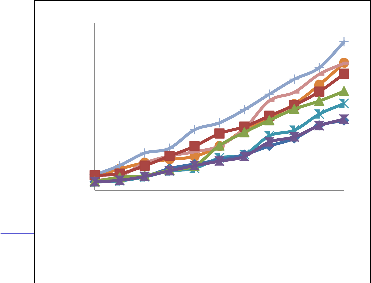

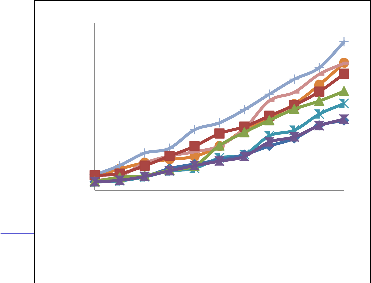

Figure 1 to 4 shows variation of NOx with respect to load. NOx increases from no load to full load at all compression ratio. This can be attributed to increase in fuel consumption as load increases, which lead to increase in temperature during combustion process thus increase NOx. Due to increase in compression ratio the temperature at the end of compression increases, hence increase in temperature

IJSER

http://ww

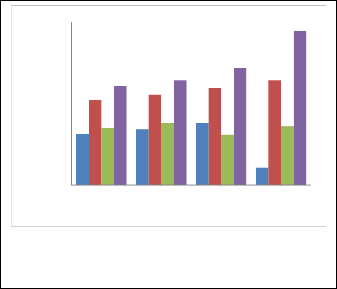

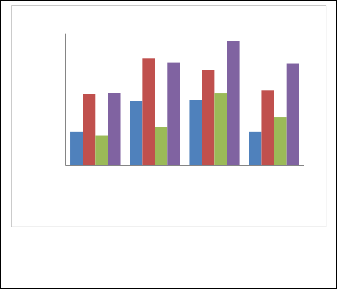

Fig. 2 Variation of NOx with respect to load at CR 10 and at ignition timing 10◦BTDC, 20◦BTDC, 30◦BTDC, 40◦BTDC for LPG and gasoline

1200

1000

800

600

400

200

0

0 0.5 1 1.5 2

load

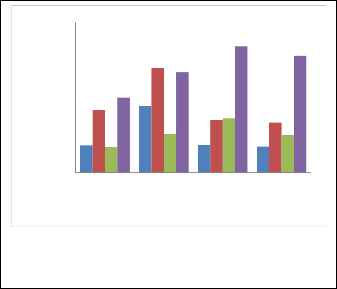

Fig. 3. Variation of NOx with respect to load at CR 11 and at ignition timing 10◦BTDC, 20◦BTDC, 30◦BTDC, 40◦BTDC for LPG and gasoline

International Journal of Scientific & Engineering Research, Volume 3, Issue 10, October-2012 3

ISSN 2229-5518

1400

1200

1000

800

600

400

200

0

0 0.5 1 1.5 2

load

1000

800

600

400

200

0

10° 20° 30° 40°

ignition timing

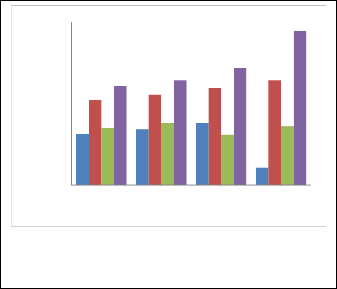

Fig. 4. Variation of NOx with respect to load at CR 12 and at ignition timing 10◦BTDC, 20◦BTDC, 30◦BTDC, 40◦BTDC for LPG and gasoline

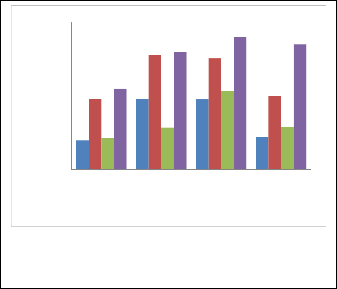

Fig. 6. Variation NOx emission at part load and peak load at CR 10

and at ignition timing 10◦BTDC, 20◦BTDC, 30◦BTDC, 40◦BTDC

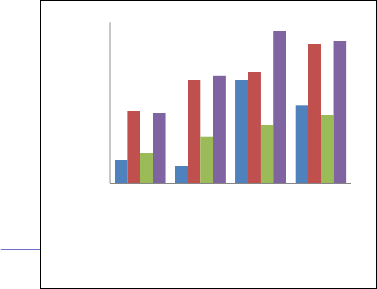

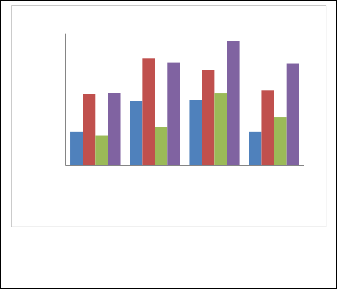

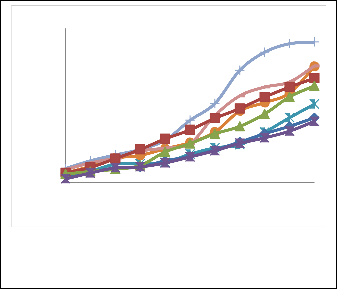

Figure 5 shows variation NOx at part load and peak load at

compression ratio 9 and at ignition timing 10◦BTDC,

20◦BTDC, 30◦BTDC, 40◦BTDC. At part load and peak load

the NOx found to be higher at 20◦BTDC in gasoline fuelled

system and at 30◦BTDC in LPG fuelled system. Similar

result was observed at higher compression ratio which is

observed in figure 6, 7 and 8. This indicates that ignition

timing also affect NOx. As it was observed that retarding

the ignition timing causes reduction in NOx formation, this

was mainly due to the drop in the peak temperature during the combustion process. On the other hand advancing the ignition timing causes rise in NOx formation due to

increase in pressure and temperature during the combustion process. As advancing the ignition timing initiates the combustion process earlier in the cycle, which in turn, moves the location of the pressure peak near to TDC, thus increasing temperature during combustion

1200

1000

800

600

400

200

0

10° 20° 30° 40°

ignition timing

process

Fig. 7. Variation NOx emission at part load and peak load at CR 11

and at ignition timing 10◦BTDC, 20◦BTDC, 30◦BTDC, 40◦BTDC

900

800

700

600

500

400

300

200

100

0

10° 20° 30° 40°

ignition timing

1400

1200

1000

800

600

400

200

0

10° 20° 30° 40°

Fig. 5. Variation NOx emission at part load and peak load at CR 9

and at ignition timing 10◦BTDC, 20◦BTDC, 30◦BTDC, 40◦BTDC

IJSER ©

http://www

load

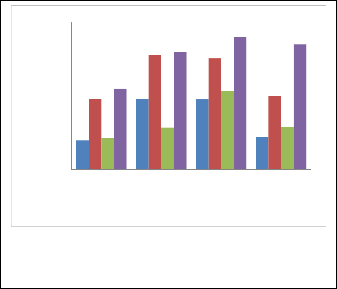

Fig. 8 Variation NOx emission at part load and peak load at CR

12 and at ignition timing 10◦BTDC, 20◦BTDC, 30◦BTDC, 40◦BTDC

International Journal of Scientific & Engineering Research, Volume 3, Issue 10, October-2012 4

ISSN 2229-5518

NOx were studied using single cylinder four stroke water cooled diesel engine converted to operate in SI mode.

Based on experimentation the following conclusion may be drawn.

1.The NOx increases steadily as load on engine increases

2. The ignition timing also affect the NOx and it was found

that retarding ignition timing it decreases. Advancing the ignition timing to certain degree BTDC increases the NOx

and further advancement decreases NOx emissions.

3. The NOx emission found to higher in LPG fuelled engine

as compare to gasoline fuelled engine

4. For gasoline fuelled engine it was found to be high at

20◦BTDC and at 30◦BTDC for LPG fuelled engine

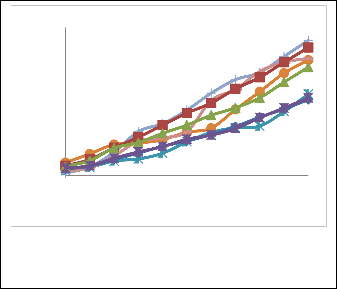

Figure 9 shows variation NOx emission at part load and peak load at compression 9, 10, 11 and12. A chart was plotted to compare NOx emission at ignition timing

20◦BTDC for gasoline fuelled engine and 30◦BTDC for LPG fuelled engine. It was observed that at part load 18% increase in NOx formation for LPG fuelled system as compare to gasoline fuelled system at each compression ratio. But at peak load it is found to be increased by 20% at CR9, 30% at CR10, 30% at CR11 and 30% at CR12, this can attributed to higher ignition temperature and superior heating value of LPG

1400

1200

1000

800

600

400

200

0

REFERENCES

[1] J. A. Yamin and O. Badran “Analytical study to minimise the heat losses from a propane powered 4-stroke spark ignition engine “renewable energy volume

27,Issue 3,November 2002

[2 ] Syed Yousufuddin, Syed Nawazish Mehdi, “ performance and emission characteristic of LPG fulled variable compression ratio engine” Turkish J Eng. Env. Sci. 32 (2008), 7-12

[3] . John B Heywood, Internal Combustion Engine Fundamentals, Mc Graw-Hill

Inc.,1988

[4] E. Ramjee and K. Vijaya Kumar Reddy “ Performance analysis of a 4-stroke SI engine using CNG as an alternative fuel” Department of Mechanical Engineering, NTUH College of Engineering, Hyderabad, July 2011

[5] N. Seshaiah, “Efficiency and exhaust gas analysis of variable compression ratio S park ignition engine fuelled with alternative fuels” M.I.T.S, Madanapalle, Angallu-517325, A.P, India 2010

9 10 11 12

load

Fig. 9. Variation NOx Emission at part load and peak load at compression 9, 10, 11 and12.

4 CONCLUSION

The influence of load and different compression ratio on

IJSER © 2012 http://www.ijser.org