International Journal of Scientific & Engineering Research, Volume 4, Issue 10, October-2013 377

ISSN 2229-5518

* M.Harinatha Reddy1 K.Vijayakumar Reddy 2 P.Nageswara Reddy3

Email: teertha_reddy@yahoo.co.in

1 Associate Professor, Sri Venkateswara Institute of Science and Technology, Kadapa,AP, India

2 Professor , JNTU College of Engineering, Kukatpalli ,Hyderabad, A.P, India

3 Principal ,Gudlavalleru college of engineering ,gudlavalleru ,Krishna Dt. A.P, India

![]()

Abstract: The use of biodiesel fuels derived from vegetable oils as a substitute for conventional petroleum fuel in diesel engines is receiving an increasing amount of attention. This interest is based on a number of properties of biodiesel, including the fact that it is produced from a renewable resource, its biodegradability, and its potential to reduce exhaust emissions. Biodiesel is a non-toxic, and renewable alternative fuel that can be used with little or no engine modification . In the first phase an experimental investigation is conducted to evaluate the effect of using blends of karanja biodiesel with conventional diesel fuel, with 10%, 20% and 30% (by volume) karanja biodiesels, on the performance and exhaust emissions of a kirloskar single-cylinder, four-stroke diesel engine. The second phase of experiments are conducted with THERMOL-D additive. The tests are conducted using each of the above , with the engine working at constant speed and five loads. Fuel consumption and exhaust regulated gas emissions such as nitrogen oxide, carbon monoxide and total unburned hydrocarbons are measured. The differences in the measured performance and exhaust emissions of karanja biodiesel -diesel fuel blends from the baseline operation of the engine, i.e. when working with neat diesel fuel, are determined and also compared with THERMOL-D additive.

Keywords: Performance; Kirloskar engine; karanja biodiesel; THERMOL-D additive ; Emissions; Diesel fuel.

![]()

Introduction

Diesel engine is a popular prime mover for transportation, agricultural machinery and industries. Diesel fuel is largely consumed by the transportation and agricultural sectors. Import of petroleum products is a major drain on our foreign exchange sources and with growing demand in future years the situation is likely become even worse. Diesel and petrol engines are the main sources of carbon dioxide, carbon monoxide and un-burnt hydrocarbon emissions and increase in carbon dioxide, carbon monoxide levels in the atmosphere leads to global warming and green house effect. The world is on the brink of energy crises. Efficient use of natural resources

is one of the fundamental requirements for any country to become self sustainable with the fossil fuel depleting very fast, researchers have concentrated on developing new agro based alternative fuels, which will provide sustainable solution to the energy crises. There are more than 300 different species of trees in India, which produces oil. Most of these trees are wild and therefore once established will look after themselves.[1] Since India is net importer of vegetable oils, edible oils cannot be used for production of bio diesel.

India has the potential to be a leading world producer

of bio diesel, as bio diesel can be harvested and sourced from non edible oils like Jatropha curcus, Pongamia pinnata, Neem,

Mahua, caster, linseed, Kusum, etc. Some of these oils produced even now are not being properly utilized. Out of these plants, India is focusing on Pongamia pinnata, which can grow in arid and wastelands. Oil content in the Pongamia seed is around 30-40%. India has about 80-100 million hectares of wasteland, which can be used for Pongamia and other non edible plants.[2] Implementation of bio diesel in India will lead to many advantages like green cover to wasteland, support to agriculture and rural economy and reduction in dependence on imported crude oil and reduction in air pollution. The engine performance and emissions of diesel engines fuelled with biodiesels have been examined by many investigators. The biodiesels used in the experiments performed by these investigators were produced from different vegetable oils such as cottonseed, sunflower, mahua, rapeseed, soybean, karanja, rubber seed, etc. In this study, the performance parameters of karanja oil methyl ester (KOME) have been calculated.

The calculations are done from theoretical data for

petroleum diesel, a single-cylinder, four-stroke diesel using diesel fuel and biodiesel which karanja oil methyl ester. And also with THERMOL-D additive.

KARANJA FUEL PROPERTIES

The comparison of chemical properties of karanja oil methyl esters(KOME) and Petroleum Diesel is as under:

4 | Calorific Value (MJ/Kg) | 36000 | 34128 | 42500 |

Engine Test

The experimental work carried out for the objective, requires an engine test set-up adequately instrumented for acquiring necessary performance and emission characteristics. Karanja methyl ester blends (Biodiesel-B10, B20 and B30) and pure Diesel were used to test a single cylinder, 4-stroke, water- cooled diesel engine having a rated output of 3.84 kW at 1500 rpm and a compression ratio of 16.5:1. The engine was coupled with rope brake dynamometer to apply different engine loads. The emissions from the engine were studied at different engine loads. After the engine reached the stabilized working condition, emissions like CO, HC and NOx were measured using an exhaust gas analyzer.

RESULTS AND ANALYSIS

This paper compares brake specific fuel consumption, brake thermal efficiency and exhaust emissions of KOME and its blends with those of diesel and also with THERMOL-D additive. Engine performance characteristics are the major criterion that governs the suitability of a fuel. This study is concerned with the evaluation of brake Thermal efficiency (BTE) and brake specific fuel consumption (BSFC) of the KOME and diesel blends with and with out THERMOL-D additive. Brake Thermal Efficiency(BTE)

S.No | PROPERTIES | KOME | Raw karanja oil | Diesel |

1 | Specific Gravity engine | 0.860 | 0.912 | 0.840 |

2 | Flash Point | 144 | 241 | 74 |

3 | Kinematic Viscosity Cst@40 °C | 4.78 | 29.65 | 2.98 |

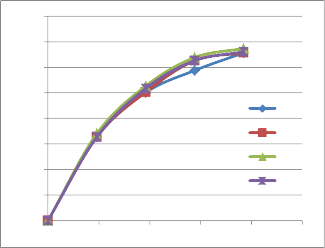

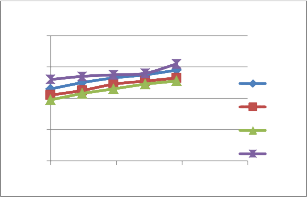

Brake thermal efficiency is defined as the ratio of energy in

the brake power, to the input fuel energy in appropriate units. The variation of Brake Thermal efficiency for different fuel blends are shown . In all the cases brake thermal efficiency is increased due reduced heat loss with increase in load. The maximum efficiency obtained in this experiment was 33.69% (K20) comparable with the maximum brake thermal efficiency for diesel 32.82% . From the above graphs, it is found that brake thermal efficiency for biodiesel in comparison to diesel

engine is a better option for part load on which most engine runs.

emissions and Carbon dioxide of karanja methyl ester and mahua methyl esters its blends with diesel.

40 BP Vs ƞ

35

30

ƞB.th (%)

25

20

15

10

Diesel K10 K20

0.55

BSFC (Kg/KWH)

0.5

0.45

0.4

0.35

0.3

0.25

0.2

0.522

0.338

0.279

0.256

Diesel K10 K20 K30

K30 5

0

0 1 2BP (KW)3 4 5

Fig.1.Variation of Brake Thermal Efficiency with Brake Power for different blends of KOME

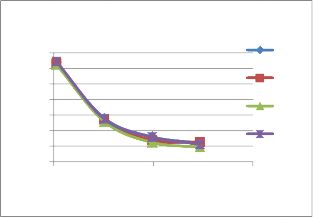

Brake Specific Fuel Consumption (BSFC)

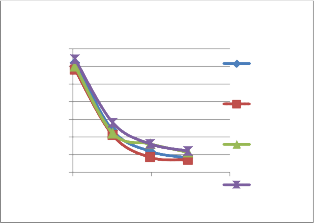

Specific fuel consumption is defined as the amount of fuel consumed for each unit of brake power developed per hour.The variation of brake specific fuel consumption of diesel and various blends of karanja methyl ester at different loads are compared . It is found that the specific fuel consumption for the blend B20 is 0.247 whereas for diesel is 0.26. However if the concentration of karanja oil in the blend is more than 30% the specific fuel consumption was found to be higher than diesel at all loads. This is because of the combined effects of lower heating value and the higher fuel flow rate due to high

density of the blends. Higher proportions of karanja oil in the

0.9 2.9 4.9

BP (KW)

Fig. 2. Variation of BSFC with Brake Power for different blends of KOME

![]()

Carbon Monoxide Emission (CO)

Carbon Monoxide is measured by an exhaust analyzer in percent (%) or parts per hundred. CO is a by product of combustion; therefore, if combustion does not take place, carbon monoxide will not be created. The emissions of carbon monoxide are toxic. Based on this premise, when a misfire occurs, the carbon monoxide that would have normally been produced during the production process is not produced. Generally speaking, on fuel injected vehicles, high CO means too much fuel is being delivered to the engine for the amount of air entering the intake manifold.

blends increases the viscosity which in turn increased the specific fuel consumption due to poor atomization of the fuel. Emission Characteristics

With problem like global warming ozone layer deletion and photochemical smog in addition to widespread air

pollution automotive emission are placed under the

0.12

0.1

0.08

0.06

0.04

0.02

0

K10 K20 K30

Diesel

microscope and every possible method is attempted to reduce emission. Hence this study compares the emission of pollutants nitrogen oxides, carbon monoxide, unburned hydrocarbon

0 2 BP 4 6

Fig. 3.Variation of CO Emission with Brake Power for different blends of KOME

Biodiesel blends give less carbon monoxide as compared to diesel due to complete combustion. When the percentage of blend of biodiesel increases, carbon monoxide decreases. This is due to more amount of oxygen content of biodiesels that result in complete combustion of the fuel and supplies the necessary oxygen to convert CO to CO2.

Hydrocarbon Emission (HC)

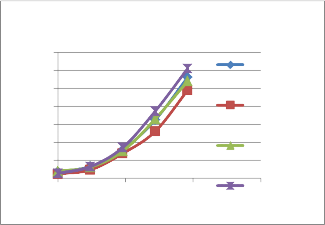

Hydrocarbons are measured by an exhaust analyzer in parts per million (ppm). As we know, HC is unburned fuel that remains as a result of a misfire. When combustion doesn't take place or when only part of the air/fuel charge burns, hydrocarbon levels goes up. It is observed that HC emission of the various blends was lower at partial load, but increased at higher engine load. This is due to the availability of less oxygen

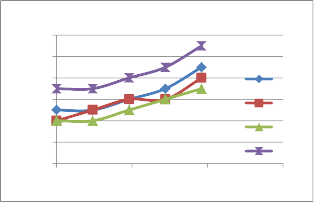

combustion. Anything which causes combustion temperatures to rise will also cause NOx emissions to rise. Misfire can also cause NOx to rise because of the increase in oxygen that it causes in the catalytic converter feed gas. NOx is more likely to cause respiratory problems such as asthma, coughing, etc.

NOx emissions are extremely undesirable. Three conditions which favor NOx formation are higher combustion temperature, more oxygen content and faster reaction rate. The above conditions are attained in biodiesel combustion very rapidly as compared to neat diesel. Hence, NOx formations for biodiesel blends are always greater than neat diesel

1500

for the reaction when more fuel is injected into the engine cylinder at higher engine load. It is also observed from the graphs that biodiesel blends give relatively lower HC as compared to the diesel. This is because of better combustion of the biodiesel inside the combustion chamber due to the

availability of excess content of oxygen in the biodiesel blends

NOx (PPM)

1000

500

0

0 2 4 6

BP (KW)

K10 K20 K30

Diesel

as compared to clean diesel. The HC emissions are almost same for all blends & neat diesel.

Fig. 5 Variation of NOX with Brake Power for different blends of KOME

80 BP Vs UBHC

UBHC (PPM)

60

40

20

0

K10 K20 K30

Diesel

0.55

BSFC (Kg/KWH)

0.5

0.45

0.4

0.35

0.3

0.25

0.2

K20+0.5ml TD

K20+1.0ml TD

K20+1.5ml TD

0 2 BP (KW) 4 6

0.9 2.9 4.9

BP (KW)

Diesel

Fig. 4.Variation of UBHC Emission with Brake Power for

different blends Of KOME

Nitrous Oxides Emission (NOX)

Nitrogen Oxides are measured by an exhaust analyzer in parts per million (ppm). Nitrogen oxides are by-products of

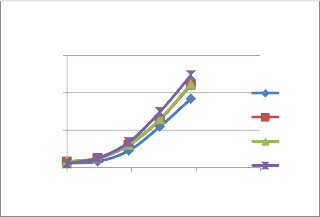

Fig. 6. Variation of BSFC with Brake Power For different THERMOL-D quantities

Fig. 6 represents the variation of specific fuel consumption with respect to brake power. With the addition of additive

there is better atomization of fuel takes place, leads to improved combustion hence fuel consumption was decreased with increase in power.

The variation of CO with brake power of diesel-biodiesel with additive is shown in Fig.7. It is observed that CO reduced in case of Esterified karanja with additive when compared to diesel. This reduction in CO is mainly due to presence of internal availability of additive content in the biodiesel. The variation of NOx with brake power of diesel-biodiesel with additive is shown in Fig.8. It is observed that NOx reduced in case of Esterified karanja with additive when compared to diesel. This reduction in NOx is mainly due to presence of internal availability of additive content in the biodiesel.

Fig.8. Variation of NOX with Brake Power For different THERMOL-D quantities

![]()

CONCLUSIONS

The present investigation evaluates the performance and emissions of Karanja methyl ester blends with diesel are compared with diesel in a single cylinder, 4-stroke water cooled diesel engine under varying load conditions of engine operations. The following conclusions are drawn from this investigation.

KOME satisfies the important fuel properties as per

ASTM specification of Biodiesel.

The existing diesel engine performs satisfactorily on biodiesel fuel without any significant engine modifications.

Engine performance with biodiesel does not differ

0.12

0.1

CO (%)

0.08

0.06

0.04

0.02

0

0 2 4 6

BP (KW)

K20+0.

5ml TD K20+1.

0ml TD

K20+1.

5ml TD Diesel

greatly from that of diesel fuel. The B20 shows good brake

thermal efficiency in comparison with diesel. A little increase in fuel consumption is often encountered due to the lower calorific value of the biodiesel.

Most of the major exhaust pollutants such as CO, CO2

and HC are reduced with the use of neat biodiesel and the blend as compared to neat diesel. But NOX emissions increase when fuelled with diesel– biodiesel fuel blends as compared to

Fig. 7. Variation of CO with Brake Power For different

THERMOL-D quantities

conventional diesel fuel. This is one of the major drawbacks of biodiesel.

Among the blends, B20 shows the better performance and

emission characteristics.

1400

1200

NOX (PPM)

1000

800

600

400

200

0

K20+0.5ml TD

K20+1ml TD

K20+1.5ml TD

Diesel

0 2 4 6

BP (KW)

In view of the petroleum fuel shortage, biodiesel can certainly be considered as a potential alternative fuel.

THERMOL-D, Bio-additive possesses many attributes as

Multi-Functional fuel additive. Its ability to reduce the surface tension between two or more interacting immiscible liquids helped the fuel to flow better through injector and better

atomization of fuel, which improved the combustion and performance of the engine at all variable loads.

� THERMOL-D also improved the pollution control.

� With proper adjustments at fuel injection pump settings bio-additives will improve performance of IC engine.

� Use of THERMOL-D, bio-additives for diesel will lead to

better fuel economy and reduced emissions and should be used by Indian refineries.

REFERENCES

Agarwal D, Kumar L and Agarwal AK (2008)Performance Evaluation of a Vegetable oil fuelled CI Engine. Renewable Energy. 33, 1147-1156.

Ali Y and Hanna M A (1994) Alternative Diesel Fuels

from Vegetable Oils. Biores. Technol. 50, 153-163.

Altõn R (1998) An experimental investigation on use of vegetable oils as diesel engine fuels. Ph.D Thesis, Gazi Univ. Institute of Sci. & Technol.

Barnwal BK and Sharma MP (2005) Prospects of

biodiesel production from vegetable oils in India. Renewable and Sustainable Energy Reviews. 9,363–378.

Canakci M and Van Gerpen J (2001) Biodiesel

production from oils and fats with high free fatty acids. Transactions of ASAE. 44, 1429-1436.

Forgiel R and Varde KS (1981) Experimental

investigation of vegetable oil utilization in a direct injection diesel engine. SAE Alternate fuels for diesel engines, SP 500 fuels and lubricants meeting Tulsa, Ok.

Forson FK, Oduro EK and Hammond-Donkoh E (2004)

Performance of jatropha oil blends in a diesel engine. Renewable Energy. 29, 1135-1145.

Harrington KJ (1986) Chemical and physical properties

of vegetable oil esters and their effect on diesel fuel performance. Biomass. 9, 1–17. 9. ISI (1980)

Methods of test for internal combustion engines. IS:

10000 Part I-XII, Indian Standards Institute, New Delhi.

Patil V and Singh K (1991) Oil gloom to oil boom, Jatropha curcas a promising agroforestry crop. Shree Offset Press, Nashik, India.

Pramanik K (2003) Properties and use of Jatropha

curcas oil and diesel fuel blends in compression ignition engine. Renewable Energy. 28, 239–248.

Raghunadham N and Deshpande N V (2004) Effect of bio-additives on IC engine performance. Natl Conf. on IC engines, VNIT, Nagpur.

Ramana KV and Raghunadham N (2004) Effect of

additives on performance of IC engines. First Natl. Conf. on Energy and Fuel Issues of Future, Pune Inst. of Engg. and Technol., India, November 5

Sarin R, Sharma M, Sinharay S and Malhotra RK (2007)

Jatropha Palm biodiesel blends: An optimum mix for Asia. Fuel, 86, 1365-1371.

Senthil Kumar M, Ramesh A and Nagalingam B (2003) An experimental comparison of methods to use methanol and jatropha oil in a compression ignition engine. Biomass and Bioenergy J. 25, 309- 318.