International Journal of Scientific & Engineering Research, Volume 4, Issue 10, October-2013 312

ISSN 2229-5518

Exergy analysis of Birla cement plant Satna: A case study

Shrikant kol1, Dr. Alok chaube2

Abstract: - Cement production is highly energy and cost intensive. The Birla cement plant requires 8760 h per year of the total operating hours to produce 1.49 Mt of clinker. In order to produce raw material preparation, clinker, preheater, rotary kiln and rotary cooler are widely used in cement plant. In this paper exergy analysis, exergy balance and exergy efficiency Birla cement plant Satna. Based on average actual operation data of the process, exergy balances have been established around the preheater, rotary kiln, rotary cooler and the whole process. Coal contributes major share fuel used in cement plant. This represents about 25% of the electricity requirement of the plant. I have recovered the 22.65MWelectricity demand reduced by using the waste heat recovery system.

Keywords: Cement production process, exergy analysis, rotary kiln and preheater system.

—————————— ——————————

INTRODUCTION

The cement production in Birla plant Satna is encountering many problems related to the waste energy, high energy cost and the environmental effects. The exergy analysis is considered as a powerful method in the performance evaluation of an engineering process. In this paper, the exergy analysis method will be used to investigate the cement production in Satna Birla plant in order to use energy more efficiently. This analysis will be conducted on the most exergy consuming units in the Satna Birla Cement plant from which the data were taken. The exergy efficiency and losses will be calculated. These calculations give a clear view of the performance of this plant. Based on these calculations, some suggestions will be given to improve this industry. The cement industry is an energy intensive industry. In India the industry accounts for 10.3% of total fuel consumption in the manufacturing sector. The energy costs account

for about 26% of the manufacturing cost of cement. In terms of the primary energy usage about 25% of the input energy is electricity while 75% is thermal energy. As energy analysis is based on the first law of thermodynamic, it has some inherent limitations like not accounting for properties of the system environment or degradation of the energy quality through dissipative process. An energy analysis does not characterize the irreversibility of processes within the system. In contrast, exergy analysis will characterize the work potential of a system. Exergy is the maximum work that can be obtained from the system, when its state is brought to the reference or “dead state” (standard atmospheric conditions). Exergy analysis is based on the second law thermodynamics. This paper will examine a detailed exergy analysis of cement plant, in order to assess the distribution of irreversibility’s and losses, which contribute to loss of efficiency in system performance.

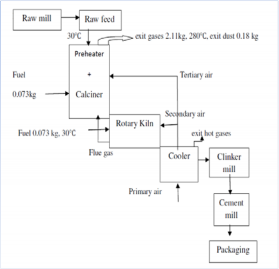

CEMENT PRODUCTION PROCESS

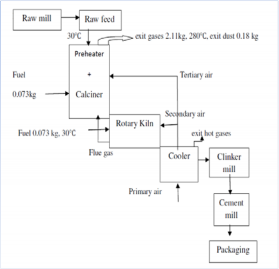

Cement production is highly energy intensive and involves the chemical combination of Calcium carbonates (limestone), silica, alumina, iron ore, and small amounts of other materials, which are chemically altered through intense heat to form a compound with binding properties. The main steps in cement production studied are illustrated in Fig. 1. These steps include mainly raw materials preparation, clinker production and finish grinding.

Raw materials preparation

Raw materials, including limestone, chalk, and clay, are mined or quarried, usually at a site close to the cement mill. These materials are then ground to a fine powder in the proper proportions needed for the cement. These can be ground as a dry mixture or combined with water to form slurry. The addition of water at this stage has important implications for the production process and for the energy demands during production. Production is often categorized as dry process and wet process. Additionally, equipment can be added to remove some water from the slurry after grinding; the process is then called semi-wet or semi-dry.

Clinker production

The mixture of raw materials enters the clinker production (or pyroprocessing) stage. During this stage, the mixture is passed through a kiln (and possibly a preheated system) and exposed to

increasingly intense heat, up to 1400℃. This

process drives off all moisture, dissociates carbon

dioxide from calcium carbonate, and transforms the raw materials into new compounds. The output from this process, called clinker, must be cooled rapidly to prevent further chemical changes.

Clinker grinding

Cooled clinker is ground in tube or roller mills and blended by simultaneous grinding and mixing with additives (e.g., gypsum, anhydrite, pozzolana, fly-ash or blast furnace slag’s) to produce the cement. Drying of the additives may be needed at this stage. Cement is an inorganic, non-metallic substance with hydraulic binding properties, and is used as a bonding agent in building materials. It is a fine powder, usually gray in color, which consists of a mixture of the hydraulic cement minerals to which one or more forms of calcium sulfate have been added. Mixed with water it forms a paste, which hardens due to formation of cement mineral hydrates. Cement is the binding agent in concrete, which is a combination of cement, mineral aggregates and water. Concrete is a key building material for a variety of applications.

EXERGY ANALYSIS OF CEMENT PALNT

Exergy is the maximum work potential of a system, stream of matter, or a heat interaction as the datum state in relation to the reference environment. Furthermore, exergy could be defined as a measure of the minimum work required to produce goods, evaluation of energy conversion, and for production systems utilization. Also exergy can be known as available energy, availability, exergy, technical work capacity, usable energy and work potential.

3.1 Exergy related to the steady matter stream (flow exergy):

The streams in cement plant can be divided into two parts: Gas streams combining with combustion products, CO2 arisen from calcinations, false air and environment air for clinker cooling, and solid streams include raw material, dust and clinker.

Physical exergy, known also as thermo- mechanical exergy, is the work obtainable by taking the substance through reversible process

exergy. There are exergy efficiency of the cement plant is defined as follows:

𝑒�𝑒𝑟�𝑦𝑜𝑢�𝑝𝑢�

from its initial state (T, P) to the state of the

environment (T0, P0).

Exergy efficiency =

𝑒�𝑒𝑟�𝑦𝑖𝑛�𝑢�

[5]

The specific physical exergy is written as:

𝑒�𝑝ℎ = (ℎ − ℎ𝑜) − �𝑜(𝑠− 𝑠𝑜) [1]

For a perfect gas with a constant 𝐶𝑝:

The exergy destroyed or the irreversibility of a system, I sys is given as:

Isys = ex input - ex output = To S gen [6]

T

T

exph = cp(T − To) − To �cpln

o

P

− Rln � [2]

Po

Where S gen is the entropy generation

SYSTEM DEFINITION AND DATA

or solid and liquids when assuming a constant

specific 𝐶𝑝:

T

T

exph = cp �T − To − To ln � − v(p − po) [3]

o

Where v is the specific volume and �𝑜is the

atmospheric temp.

Chemical exergy is equal to the maximum amount of work obtained when the substance under consideration is brought from the environmental state (T0, Po) to the dead state (T0, P0, μ0i) by processes involving heat transfer and exchange of substances only with the environment. The specific chemical exergy exch at P0 can be calculated by bringing the pure component in chemical equilibrium with the environment. For pure reference components, which also exist in the environment, the chemical exergy consist of the exergy, which can be obtained by diffusing the components to their reference concentration P. The specific molar chemical exergy of a reference component i present in the environment at partial pressure Pi is:

𝑒�𝑐ℎ = Σ𝑥�(𝑒�𝑐ℎ𝑜�+ 𝑅�𝑜ln(𝑥�)) [4]

Where xi represents the molar fraction of

component i and 𝑒�𝑐ℎ𝑜𝑖is the standard chemical

SOURCE

The cement plant considered is Birla cement plant Satna Madhya Pradesh, India. The plant runs on dry process with five stage suspension preheater.

Operation data of the process | |

Productivity | 4100 T/d |

Specific fuel consumption | 0.106 kg coal kg*/kg cli. |

Specific heat consumption | 4323.5kJ/kg cli |

- % fuel in calciners | 39% |

- Raw meal / clinker factor | 1.92 |

-precalcination deg. in calciner | 90% |

Preheater exit gas temp. | 260 -280 0C |

- Preheater exit dust | 0.91kg/kgcli. |

O2 % in preheater exit gas | 5% |

By pass kiln gas temp. | 10000C |

- By pass kiln gas dust | 0.109kg/kgcli. |

O2 % in by pass kiln gas | 2.7% |

Clinker outlet temp. from kiln | 14000C |

Injected water in the cooler (to assist cooling operation) | 10 m3 / hr 0.057 kg/kg cli |

Temp. of hot air from cooler | 800 0C |

Temp. of clinker from cooler | 100 0C |

- % fuel in kiln | 69% |

The production capacity is 4100 ton per day. The specific energy consumption for the plant is 3.99GJ per ton of clinker and 87 kWh of electricity

per ton of cement.

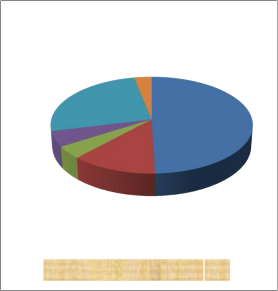

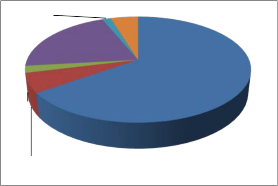

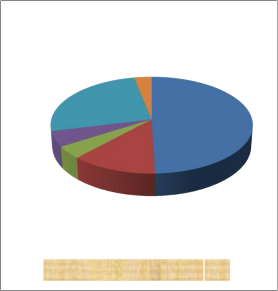

MgO, CO2,

0.97%

FeO, 1.40%

SiO2, 13.74%

3.11%

CaO, 43.31%

Al2O3, 3.95%

Fig. 3 Chemical compositions of raw materials

Figure no. 1 plant layout

RESULT AND DISCUSSION

Mass and exergy balance around the process

Preheater

Table no 01 show the mass and exergy balance

Input items | Mass kg | Temp ◦C | Cp kJ/kg cl | Exergy kJ/kg cl |

Raw meal | 1.92 | 30 | 0.83 | 0 |

Fuel coal | 0.073 | 30 | 0.83 | 3170 |

Tertiary air | 0.85 | 800 | 1.08 | 355.13 |

Fresh air | 0.559 | 30 | 1.004 | 0 |

Water vapour | 0.032 | 800 | 2 | 24.75 |

Total | 3.465 | | | 3549.38 |

Output items | | | | |

Hot meal | 1.17 | 800 | 1.002 | 453.53 |

Flue gases | 2.11 | 280 | 1.09 | 155.78 |

Flue dust | 0.81 | 280 | 1 | 54.84 |

Reaction | | | | 8.4 |

Evaporative water | | 100 | | 59.1 |

Wall loss | | | | 1334.5 |

Total | 3.46 | | | 2066.15 |

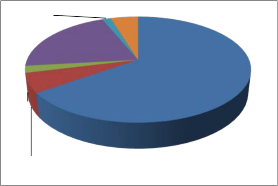

Hydrogen, 3%

Sulphur, 5%

Oxygen, 4%

Ash, 25%

Moisture, 12%

Carbon, 48%

Calculate the Preheater and Precalciner exergy efficiency = 58.2%

Fig. 2. Composition of coal

Exergy destruction for Preheater Precalciner

= input exergy- output exergy

= 1483.6 kJ/kg cl

From exergy balance preheater it is found that:

The largest exergy output items from preheater is the chemical exergy of the reactions followed by exergy of the hot meal then the exergy of exit flue gases and dust.

Rotary cooler

Table no 03 Mass and exergy balance

Input items | Mass Kg | Temp ◦C | Cp kJ/kg cl | Exergy kJ/kg cl |

Hot clinker | 1 | 1400 | 1.09 | 928.98 |

Injected water | 1.24 | 30 | 1 | 0 |

Primary air | 0.054 | 30 | 4.18 | 0 |

Total | 2.29 | | | 928.98 |

Output items | | | | |

Clinker | 1 | | 0.82 | 5.7586 |

Hot air | 1.294 | | 1.08 | 772.008 |

Total | 2.294 | | | 777.75 |

Rotary kiln:

Table no 2 shows the mass and exergy balance

Input items | Mass Kg | Temp. ◦C | Cp kJ/kg cl | Exergy kJ/kg cl |

Hot meal | 1.17 | 800 | 1.002 | 453.534 |

Fuel | 0.033 | 30 | 1.085 | 1433.19 |

Hot gases from cooler | 0.016 | 800 | 2 | 7.175 |

Secondary air | 0.41 | 800 | 1.08 | 171.30 |

Primary air | 0.166 | 30 | 1.004 | 0 |

Total | 1.795 | | | 2065.199 |

Output items | | | | |

Clinker | 1 | 1400 | 1.09 | 975.581 |

By pass dust | 0.109 | 1000 | 1.07 | 65.72 |

Flue gases | 0.704 | 1000 | 1.09 | 438.17 |

Wall loss | | | | 128.4 |

Clinker formation | | | | -0.6 |

Dust formation | | | | -0.06 |

total | | | | 1607.211 |

Calculate the kiln exergy efficiency

= 77.82%

Exergy destruction for kiln

= input exergy- output exergy

= 457.988kJ/kg cl

As the compare exergy balance rotary kiln and preheater, rotary kiln exergy lost is less than in the preheater.

Rotary cooler exergy efficiency

= 83.72%

Exergy destruction from cooler

= 151.23 kJ/kg cl

As clear from mass and exergy balance around the cooler, maximum exergy lost hot air. Compare exergy balance Preheater, rotary kiln and rotary cooler maximum exergy lost preheater. Compare the exergy destruction Preheater Rotary Kiln and Rotary cooler

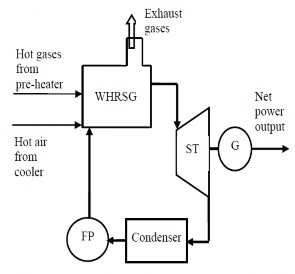

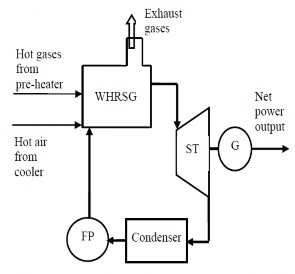

WASTE HEAT RECOVERY SYSTEM

There are opportunities that exist within the plant to capture the heat that would otherwise be wasted to the environment and utilize this heat to generate electricity. The most accessible and, in turn, the most cost effective waste heat losses available are the clinker cooler discharge and the preheater exit gas. The exit gases from the

preheater on average, 280℃ and exit cooler gas temperature on average 280℃. Both the streams

would be directed through a waste heat recovery

steam generator, and the available energy is transferred to water via the WHRG. The available waste energy is such that steam would be generated. The electricity generated would offset apportion of the purchased electricity, thereby reducing the electricity demand. [6]

We assume an overall efficiency of 80% for the steam generator. As the gas passes through the Waste Heat recovery generator, energy will be transferred and the gas temp will be drop. A pressure of 10 bars at the turbine inlet, the minimum stream temperature at the waste heat recover generation exit would be higher than the corresponding saturation temperature, which are

180℃. Exergy in waste heat recovery and turbine

work, according to the temperature of stream, the

enthalpy calculated to be 2778.1kJ/kg and 2643.7kJ/kg. Therefore, the turbine work would be:

Ex in =262kJ and Ex out = 200kJ Turbine work per unit mass = h1-h2

=134.5kJ/kg

Total turbine work = 477.47 kJ/s

Then cement production 4100 ton per day and the electricity generate

= 22657.71kW

Required electricity per day =356700kW Electricity save per day = 22657.71kW

And Energy saved per annum

= (electricity generated) x( hours of usage)

= 477.47x 8760

= 4.18x106kWh/y

Figure no. 5 waste heat recovery process

CONCLUSION

The aim of this study is to determine and analyze exergy utilization, exergy balance and their irreversibility in Birla cement plant. Mass and exergy analysis of general process and recovery process were carried out using the actual plant operational data. The major heat loss sources have been determined as preheater and rotary cooler.

Exergy analysis is a powerful tool, which has been successfully and effectively used in the design and performance evaluation of energy related systems.

The exergy analysis for each co- generation system is examined and a parameter optimization for each cogeneration system is achieved by means of genetic algorithm to reach the maximum exergy efficiency .The optimum performances for different cogeneration systems are compared under same condition.

To reduce the two main losses as discussed, a conventional WHRSG system is proposed. Calculations showed that 22.65MW/day electricity demand reduced.

REFERENCES

[1] Wendell de Queiroz Lamas, Jose Carlos Fortes Palau, Jose Rubens de Camargo. Waste materials co-processing in cement industry: Ecological efficiency of waste reuse. Renewable and Sustainable Energy Reviews19 (2013) 200-207

[2] SteffenWeil, Stefan Hamel, Wolfgang Krumm. Hydrogen energy from coupled waste gasification and cement production-a thermo chemical concept studies. International Journal of Hydrogen Energy 31 (2006) 1674 -1689

[3] J. U. Ahamed, N. A. Madlool, R. Saidur, H.

H. Masjuki, M. I. Shahinuddin, and A. Kamayar, “Assessment of energy and exergy efficiencies of a great clinker cooling system through the optimization of its operational parameters,” Energy, article in press, 2012.

[4] M.G. Rasul, W. Widianto, B. Mohanty.

Assessment of the thermal performance and energy conservation opportunities of a cement industry in Indonesia. Applied Thermal Engineering 25 (2005) 2950–2965

[5] Jiangfeng Wang, Yiping Dai *, Lin Gao.

Exergy analyses and parametric optimizations for different cogeneration power plants in cement industry. Applied Energy 86 (2009)

941–948

[6] Mauricio Naranjo, Darrell T. Brownlow and Adolfo Garza. CO2 Capture and Sequestration in the Cement Industry. Energy Procedia 4 (2011) 2716–2723

[7] Shaleen Khurana, Rangan Banerjee. Energy balance and cogeneration for a cement plant. Applied Thermal Engineering 22 (2002) 485–

494

[8] Wendell de Queiroz Lamas, Jose Carlos Fortes Palau, Jose Rubens de Camargo. Waste materials co-processing in cement industry: Ecological efficiency of waste reuse. Renewable and Sustainable Energy Reviews19 (2013) 200-207

[9] Unal Camdali Ali Erisen. Energy and exergy analyses in a rotary burner with pre- calcinations in cement production. Energy Conversion and Management 45 (2004)

3017–3031

[10] G. Oggioni, R. Riccardi, R. Toninelli. Eco- efficiency of the world cement industry: A data envelopment analysis. Energy Policy 39 (2011) 2842–2854

[11] G. Kabir, A.I. Abubakar, U.A. El-Nafaty.

Energy audit and conservation opportunities for pyroprocessing unit of a typical dry process cement plant. Energy 35 (2010)

1237–1243

[12] Cesar Valderrama, Ricard Granados, Jose Luis Cortina. Implementation of best available techniques in cement manufacturing a life-cycle assessment study. Journal of Cleaner Production 25 (2012) 60e67

[13] Rachel Woodward, Noel Duffy. Cement and concrete flow analysis in a rapidly expanding economy Ireland as a case study. Resources, Conservation and Recycling 55 (2011) 448-

455

[14] Hrvoje Mikulcic, Milan Vujanovic, Neven Duic. Reducing the CO2 emissions in Croatian cement industry, Applied Energy

[15] N. Hamidi, M. Omidvari, M. Meftahi. The

effect of integrated management system on safety and productivity indices Case study; Iranian cement industries. Safety Science 50 (2012) 1180–1189

[16] Tahsin Engin, Vedat Ari. Energy auditing and recovery for dry type cement rotary kiln systems––A case study. Energy Conversion and Management 46 (2005) 551–56

DETAILS ABOUT AUTHORS

[Author 1]

Mr.Shrikant kol is a student of final year Master of Engineering (Heat Power Engineering) Engineering studying at department of Mechanical Engineering JEC, Jabalpur Madhya Pradesh India.

[Author 2]

Dr. Alok Chaube Head of Department Mechanical, Jabalpur Engineering. College Jabalpur / R.G.P.V. Bhopal, Madhya Pradesh India.

Email Address: alokchaube@rediffmail.com, Mobile No. 09425386512

![]()

![]()

![]()