International Journal of Scientific & Engineering Research, Volume 5, Issue 12, December-2014 903

ISSN 2229-5518

Ergonomic Evaluation of Knapsack Sprayer used in Agricultural Application

Pravin K. Bhuse1, Ravindra T. Vyavahare2

Abstract— In India most of the agricultural operations are performed manually by agricultural workers using hand tools and equipments. The economic growth and technological improvements have lead to greater demand and development of machines and devices used in industrial settings. W ith these dramatic changes there has also been greater interaction between man and machines. It is important to design these tools using ergonomic principles for increasing efficiency of the operation, safety and comfort of user. This paper presents ergonomic assessment of knapsack sprayer which is commonly used by farmers for spraying insecticides and pesticides. Present study analyzes various postures of farm worker during the operation of knapsack sprayer. Analysis uses modules of CATIA like Human Builder, Human Activity Analysis and Rapid Upper Limb Assessment (RULA) analysis. Improvements in the design of knapsack sprayer were made

to make sprayer ergonomically suitable for 5th to 95th percentile population.

Index Terms— Agricultural equipments, Anthropometry, Ergonomics, Human Activity Analysis, RULA, Maharashtra, Knapsack sprayer,

—————————— ——————————

In a large number of agriculture applications, hand equip- ments are important equipments [1]. In many occupations, some of the major reasons of work-related injuries and disease are linked to the use of hand equipments [2]. It has shown that tool design may play an important role in development of work related problems in the upper limbs. Poor design of hand equipments may result in cumulative trauma disorders [3]. Occupational accidents can be linked directly to the use of specific hand equipments.

Ergonomically well designed hand equipments may reduce

the discomforts. It also provides comfortable work for the us-

ers and gives high product quality to the consumers. As the

use of hand equipments may play an important role in the development of disorders and accidents, it is obvious that im- provements in the design of hand equipments are essential for promoting professional users health, particularly where there is intensive exposure. Newly adopted design software tech- niques can use for ergonomic evaluation.

Ergonomic evaluation will consist of an initial assessment,

which includes looking at the overall posture of your head,

neck, back, upper body, forearms, wrists, hands, legs and feet.

It includes things like repetitious movement, forces, contact

stress, static loading and environmental factors. Ergonomic

dimensions correspond best to the orientation of the designed hardware which is registered in different positions and pos- tures that simulate the real working postures and positions in the conventional form. Hence, to achieve better efficiency,

————————————————

• 1Department of Mechanical Engineering, SKN Sinhgad College of Engg., Pandharpur, Maharashtra, India

E-mail: pravinbhuse7@gmail.com

• 2Department of Mechanical Engineering, SKN Sinhgad College of Engg., Pandharpur, Maharashtra, India

E-mail: rtv_101@yahoo.com

limitations.

This study uses 33 anthropometric parameters of male ag- ricultural workers from four districts of Western Maha- rashtra [4]. Table 1 presents standard deviation and mean.

Table 1: Anthropometric Data Analysis Sheet

human comfort and safety, it is necessary to design the equipment keeping in view the operator’s capabilities and

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 12, December-2014 904

ISSN 2229-5518

Fig. 1. Digital manikin designed in Human Builder

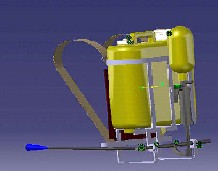

Fig. 2. Existing sprayer model modelled in CATIA

Fig. 3. Lance model of existing sprayer modelled in CATIA

In CATIA V5R18, Anthropometric data is fed to CATIA in sws format using Human Builder tool, which creates digital mani- kin of particular anthropometry (Fig. 1). Human Builder gives many options like gender selection, percentile selection, edit- ing human anthropometry. In this study two percentile values

5th and 95th percentile are considered.

Most used model of sprayer was taken into consideration. All parts of sprayer like tank, stand, handle, straps and handle were modelled in CATIA (Fig. 2 and 3)

Angle of stroke of handle is calculated as well as lance move- ments were also taken into consideration. Model of sprayer was adjusted to digital manikin as per posture. In this analysis right handed person was considered. As per calculated angles simulation was created. From the simulation, three postures for left side of body (upper extreme, middle, lower extreme) were taken into consideration and RULA score was calculated (Table.2 and 3). For right handed person, sprayer handle and lance were in left and right hand respectively.

Fig. 4 (a) Upper Posture Fig. 4 (b) Middle posture

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 12, December-2014 905

ISSN 2229-5518

Wrist and arm | 4 | 4 |

Neck | 1 | 1 |

Trunk | 1 | 1 |

Leg | 1 | 1 |

posture B | 1 | 1 |

Neck, trunk and leg | 1 | 1 |

Final score | 3 | 3 |

Fig. 4(c) Lower Posture

Part of body | 95th | 5th | ||||

Part of body | U | M | L | U | M | L |

Upper arm | 3 | 4 | 4 | 3 | 3 | 3 |

Forearm | 2 | 3 | 3 | 3 | 3 | 3 |

Wrist | 3 | 3 | 3 | 2 | 2 | 2 |

Wrist twist | 1 | 1 | 1 | 2 | 2 | 2 |

Posture A | 4 | 5 | 5 | 4 | 4 | 4 |

Muscle | 1 | 1 | 1 | 1 | 1 | 1 |

Wrist and arm | 5 | 6 | 6 | 5 | 5 | 5 |

Neck | 1 | 1 | 1 | 1 | 1 | 1 |

Trunk | 1 | 1 | 1 | 1 | 1 | 1 |

Leg | 1 | 1 | 1 | 1 | 1 | 1 |

posture B | 1 | 1 | 1 | 1 | 1 | 1 |

Neck, trunk and leg | 2 | 2 | 2 | 2 | 2 | 2 |

Final score | 4 | 4 | 4 | 4 | 4 | 4 |

(U-upper posture, M-middle posture, L- lower posture)

In this analysis upper arm abduction, shoulder elevation, arm

rotation and wrist deviation observed beyond the critical val- ues. From above table it is clear that for all postures of left side, final score is 4. In For right side of body, whole simula- tion shows same RULA (Rapid Upper Limb Assessment) score which is 3(Table 3).

For design modification, first various postures were studied in human activity analysis. From that study, simulation of best postures was determined. Ergonomically best suited design of lance and handle was developed according to simulation in CATIA (Fig. 5).

Fig. 5. Modification in lance and handle in CATIA

After modification in CATIA, it was noticed that there was

requirement of adjustable length handle for 5th and 95th per-

centile manikin from 493 mm to 592 mm.

Part of body | 95th | 5th |

Upper arm | 3 | 3 |

Forearm | 3 | 3 |

Wrist | 3 | 3 |

Wrist twist | 1 | 1 |

Posture A | 4 | 4 |

Muscle | 0 | 0 |

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 12, December-2014 906

ISSN 2229-5518

Wrist | 2 | 2 |

Wrist twist | 1 | 1 |

Posture A | 2 | 2 |

Muscle | 0 | 0 |

Wrist and arm | 2 | 2 |

Neck | 1 | 1 |

Trunk | 1 | 1 |

Leg | 1 | 1 |

posture B | 1 | 1 |

Neck, trunk and leg | 1 | 1 |

Final score | 2 | 2 |

Fig. 6. Digital Manikin with modified sprayer

First suitable handle length (592 mm) was taken for 95th per-

centile digital manikin in simulation (Fig. 7). RULA score was calculated for all posture. For 5th percentile, length was varied to 493mm (Table 4).

According to CATIA modification, lance and handle was de- veloped in proper dimension (Fig 5 and 6). Five male opera- tors who had good experience at the controls and operating sprayer were selected. Overall discomfort rating (ODR) was used which was developed by Corlett and Bishop for the as- sessment of trial. Trial was conducted for both models. The subjects operated the sprayer for half an hour. To determine the discomfort level, overall discomfort rating method (ODR) was used.

In ODR, some questions were asked to worker related to mod-

ifications. Farmer’s ratings were found improved for adjusta- ble handle length, adjustable angle of grip, modified lance and nozzle.

Subject no | Subject ODR | |

Subject no | Existing Sprayer | Modified sprayer |

1 | 6 | 4 |

2 | 7 | 5 |

3 | 7 | 4 |

4 | 5 | 3 |

5 | 7 | 3 |

Final | 6.4 | 3.8 |

(U-upper posture, M-middle posture, L- lower posture)

From table it is observed that final score for all posture is 3.

For right side of body final score are 2.

ODR analysis gave final score 6.4 and 3.8 for existing sprayer

and modified sprayer respectively. Final score is average of all

5 workers score.

Fig. 7. Modified handle

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 12, December-2014 907

ISSN 2229-5518

Fig. 8. Modified lance

Fig.9. Farm worker with modified sprayer

From above study, it is observed that final RULA score is re- duced for the modified sprayer. ODR analysis also shows that modified product performs better on ergonomic aspect.

Thus the postures of the human body can be analyzed by us-

ing RULA analysis in order to analyse existing product or the

design of new product. This is because the posture of human

body reflect the design of the product ergonomically. If the

product is ergonomically sound, the person working will work in the best posture with no risk of injury from the work.

• This study indicates that an ergonomic design of a hand tool is important.

• Ergonomic evaluation can be a step towards im- provement of the product reducing musculascalatan disorders.

• It is possible to make ergonomically sound hand tools using digital human modeling and RULA analysis.

• The design of a hand tool reflects the posture of the users. Hence an ergonomic well design hand tool will improve the user postures.

1. Chao A, Kumar A, Nagarajrao K and You H, “An Ergonomic evaluation of

Cleco Pliers”, HFES 2000 Congress, 441-442, 2000.

2. Dewangan K., Owary C. and Datta R., “Anthropometric data of female farm

workers from north eastern India and design of hand tools of the hilly region”, International Journal of Industrial Ergonomics, 38, 90–100, 2008.

3. Paquet V. and Feathers D., “An anthropometric study of manual and powered

wheelchair users”, International Journal of Industrial Ergonomics 33, 191–

204, 2004.

4. Bhuse P. and Vyavahare R., “Anthropometric Measurements and Grip

Strength of Western Maharashtra Agricultural Workers”, International Jour- nal of Latest Trends in Engineering and Technology, 4(2), 126-132, 2014.

5. Agrawal K. N., Singh R. K. and Satapathy K. K., “Anthropometric consider-

ations for farm tools/machinery design for tribal workers of North Eastern In- dia”, Agricultural Engineering International: the CIGR Ejournal, Manuscript MES 1406 Vol. XII, 2010.

6. Baral P., Lobo S., Menezes R., Kanchan T and Krishan K., Bhattacharya S., Hiremath S., “An anthropometric study of facial height among four endoga- mous communities in the Sunsari district of Nepal”, Singapore Med J, 51(3),

209-212, 2010.

7. Chandra A., Chandana P. and Deswal S., “Analysis of hand anthropometric dimensions of male industrial workers of Haryana state”, International Journal

of Engineering (IJE), 5(3), 242-256, 2011.

8. Goel K., Behera D., Behera B. K., Mohanty S. K. and Nanda S. K., “Devel- opment and Ergonomic Evaluation of Manually Operated Weeder for Dry

Land Crops”, Agricultural Engineering International, 9(5), 1-8, 2008.

9. Hasio H., Whitestone J., Bradtmiller B., Whisler B., Zwiener J., Lafferty C., Kau T. and Gross M, “Anthropometric criteria for the design of tractor cabs

and protection frames”, Ergonomics, 48(4), 323-353, 2005.

10. Khidiya M and Bhardwaj A, “Design, development and ergonomics evalua- tion of a hand operated spade (phawra)”, HFESA Journal, Ergonomics Aus-

tralia Vol 24, 200-209, 2010.

11. Khogare T. and Borkar s., “Anthropometric data of agricultural workers for suggesting dimensions of manually operated weeder”, Asian journal of home

science, 6(1), 57-60, 2011.

12. Kumar S., “Arm lifts strength in workplace”, Applied Ergonomics, 22 (5),

317-328, 1991.

13. Kumara A., Mohan D., Patel R. and Varghese M., “Development of grain threshers based on ergonomic design criteria”, Applied Ergonomics, 33,

503–508, 2002.

14. Lin C., “Ergonomic Assessment of Excavator Seat”, International Journal of

Applied Science and Engineering 9(2), 99-109, 2011.

15. Mehta R., Tiwari P., Rokade S., Pandey M., Pharade S., Gite L., and Yadav

S. B., “Leg strength of Indian operators in the operations of tractor pedals”, In- ternational Journal of Industrial Ergonomics, 37(4), 303-311, 2007.

16. Mukhopadhyay P. and Srivastava S., “Ergonomics risk factors in some craft

sectors of Jaipur”, HFESA Journal, Ergonomics Australia Vol 24, 1991.

17. Nag P., Agricultural Ergonomics, 263–264, 1992.

18. Sanjog J., Karmakar S., Agarwal H., Dattu C., and Patil K., “Designing and

Ergonomic Evaluation of a Shoe-Rack in CAD Environment”, International

Journal of Computer Applications, 49(20), 0975 – 0982, 2012.

19. Yadav R. and Pund S., “Development and Ergonomic Evaluation of Manual

Weeder”, Agricultural Engineering International: CIGR Ejournal. Manuscript

PM 07 022. 9(3), 2007.

20. Yadav R., Pund S., Patel N and Gite L, “Analytical study of strength parame-

ters of Indian farm workers and its Implication in equipment design”, Agricul- tural Engineering International Journal, 9, 1-8, 2010.

IJSER © 2014 http://www.ijser.org