The vehicle mechanical load is characterized by many torqueses, which are considered resistive. The different

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 1322

ISSN 2229-5518

Akshay aggarwal

each wheel so that all wheels are supplied with the torque they need. The proposed control structure is based on the PID

control for each wheel motor. PID Control system is then evaluated in the Matlab/Simulink environment. Electronic

differential have the advantages of replacing loosely, heavy and inefficient mechanical transmission and mechanical

differential with a more efficient, light and small electric motors directly coupled to the wheels using a single gear reduction or an in-wheel motor.

—————————— ——————————

The heavy body including the structure and materials used in Electric Vehicle has always been a field of interest to designers. Their continuous research work to reduce the weight of the body has interested many people worldwide. The main attraction has always been reduction of body mass, including structure and form optimization or by adopting aluminum materials. Vehicles have seen an improvement on both motor design and control technology. Modern configurations

include motorized wheels, where motors are fitted in the wheels of EVs and thus improve air quality, reducing

the reliance on fossil fuels of power vehicles.

Here we ponder upon the use of Electronic Differential

(ED), replacing the conventional gearbox and the usual

configuration of EVs with only one traction-motor driving two wheels. It reduces the overall mass of an EV by replacing the conventional mechanical differential. Now the speed reference computation in the double- driven EV can be controlled by ED through the torque/rotation-speed curve of an electric motor which is almost perfectly adapted to the resistance-torque/speed curve of an electric vehicle. In case of curvilinear

trajectory or a lane change each wheel is controlled

through an ED in order to satisfy the motion requirements.

The vehicle mechanical load is characterized by many torqueses, which are considered resistive. The different

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 1323

ISSN 2229-5518

torques include: – The vehicle inertial torque defined by

the following relationship:

Fres = froll + faero + fslope

Froll = µ.mg

Faero = 1/2pCxSv2

Fslope =Mg.sinα

The main purpose of the electronic differential (ED) is to substitute the mechanical differential in multi-drive systems, providing the required torque for each driving wheel and allowing different wheel speeds.![]()

𝑑𝑤. 𝑡𝑎𝑛𝛿

∆𝑤 = 𝑤𝑟𝐿 − 𝑤𝑟𝑅 = 𝑤𝑉

𝐿𝑤

𝛿 > 0 ⇒ 𝑇𝑢𝑟𝑛 𝑅𝑖𝑔ℎ𝑡

𝛿 = 0 ⇒ 𝑆𝑡𝑟𝑎𝑖𝑔ℎ𝑡 𝑎ℎ𝑒𝑎𝑑

𝛿 < 0 ⇒ 𝑇𝑢𝑟𝑛 𝑙𝑒𝑓𝑡

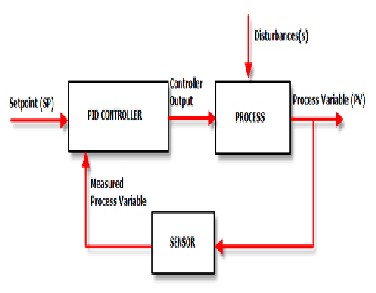

A proportional-integral-derivative controller (PID controller) is a family of controllers. They are the solution of choice when a controller is needed to close the loop and gives the designer a larger number of options and those options mean that there are more possibilities for changing the dynamics of the system in a way that helps the designer. A PID controller calculates an "error" value as the difference between a measured process variable and a desired set point. The controller attempts to minimize the error by adjusting the process control inputs.it takes the in wheel encoder values as feedback and will check it again and again in closed loop to reduce the error.![]()

𝑣𝐿 = 𝑤𝑉 �𝑅 +![]()

𝑑𝑤

�

2

𝑣𝑅 = 𝑤𝑉 �𝑅 −![]()

𝑑𝑤

�

2

𝑅 =![]()

𝐿𝑤

𝑡𝑎𝑛𝛿

PID controllers can be viewed as three terms - a proportional term which provides an overall control

𝑤𝑟𝐿 =

𝑤𝑟𝑅 =![]()

𝐿𝑤 + 𝑑𝑤 𝑡𝑎𝑛𝛿

𝐿𝑤![]()

𝐿𝑤 − 𝑑𝑤 𝑡𝑎𝑛𝛿

𝐿𝑤

𝑤𝑉

𝑤𝑉

action proportional to the error signal through the all

pass gain factor, and integral term, reducing steady state

errors through low frequency compensation by an

integrator and a derivative term, improving transient

response through high-frequency compensation by a

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 1324

ISSN 2229-5518

differentiator - added together. PID controllers are also known as three-term controllers and three-mode controllers.

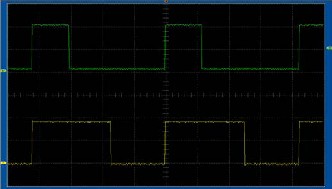

Two DC hub motors are used in this case. The Electronic

control unit carries out the following basic tasks:

1. Reads the calibrated steering angle potentiometer

voltage and based on this it then calculates the steering

angle and also determines whether the vehicle is moving straight, turning left or right.

2 .Reads the throttle potentiometer voltage so that the desired vehicle speed is known.

3. Based on the above information, the ratio of the two

speeds VL/VR is calculated using the appropriate equation such as Equation shown earlier

4. A separate Pulse Width Modulated (PWM) signal is then applied to each of the two motors in accordance with the required speed ratio.

The above sequence is repeated at an extremely fast rate so that the ECU continues to make adjustments on a continuous basis

The CAN bus (controller area network) is a vehicle bus standard. It communicates with the microcontrollers and devices within a vehicle without a host computer. CAN bus is a message-based protocol, designed specifically

for automotive applications. CAN is a multi-master

broadcast serial bus standard for connecting electronic

control units (ECUs).

Here we are using embedded Atmel controllers family

with embedded can. CAN controller will help us to communicate within the vehicle up to a speed of 1 mbps without any host computer, to get the data from sensors at very high speed in serial communication. The can controller is designed in matlab.

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 1325

ISSN 2229-5518

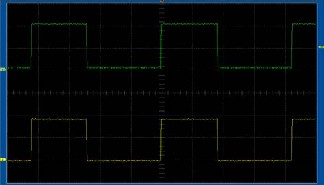

Initially when the throttle input is 1.7 volt.

When steering wheel is turned left

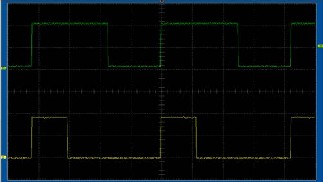

When the steering wheel turned right

In this paper, a PID controller has been used for an electronic differential to control two-independent-wheel drive electric vehicle. The electronic differential has been discussed over mechanical differential, proving it to be a better device with better features implemented in it. The results of the electronic differential system operated satisfactorily and that a two-wheel-individual drive electric vehicle can operate smoothly on both a straight or curved path using a PID closed loop control system.

1. Kada HARTANI, Mohamed BOURAHLA ,Yahia MILOUD, Mohamed SEKOUR ”Electronic Differential with Direct Torque Fuzzy Control for Vehicle Propulsion System” Vol.17, No.1, 2009©TUBITAK doi:10.3906/elk-0801-

2. P. Presage, R. Krishnan. “Modelling, Simulation, and Analysis of Permanent Magnets Motor Drives, Part I: The Permanent Magnets Synchronous Motor Drive,”IEEE Transactions on Industry Applications Vol.25, no.2, 265-273, 1989.

3.K.H. Nag, G. Chang, Y. L: PID Control System Analysis, Design and Technology, IEEE Transaction on Control System Technology, Vol. 13, No. 4, July 2005, pp. 559 – 576

4. Milliken, F.W.; Milliken, D.L.: ‘Rave Car Vehicle

Dynamics’, SAE International, 1995.

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 1326

ISSN 2229-5518

5. R.E. Colyer et al., “Comparison of steering

geometries for multiwheeled vehicles by

modelling and simulation,” in Proceedings of

IEEE CDC'98, vol. 3, pp. 3131-3133, December

1998.

6. A. Ece Hartavi et al., “Signal interfacing for hybrid electric vehicular electronics and an implementation study,” in Proceedings of the IEEE ICVES’08, Columbus, OH (USA), pp. 151-

156, September 2008.

IJSER © 2013 http://www.ijser.org