International Journal of Scientific & Engineering Research, Volume 5, Issue 6, June-2014 887

ISSN 2229-5518

Abstract— Broken rice such as KSK-133 is processed due to low quality and economic reasons. The effects of temperature, pH and steeping time on rice starch extraction from low quality rice KSK-133 investigated. Starch was extracted from rice by alkaline extraction technique. The main objective is to obtain high starch content from KSK-133. The independent variables are temperature, pH and steeping time. Rice starch was extracted at five different temperatures (22, 25, 30, 35 and 40oC). As well as rice starch was also extracted at five different pHs (7, 8, 8.5, 9.0 and 9.5). In a steeping process dis- tilled water used with 0.1M caustic soda for required pHs, kept the steeping hours (18, 22 hrs.) in every trial for each pH and temperature. Maximum rice starch has been recovered that is (85-95.4) % for five different temperatures in both steeping hrs. at 9.5pH. At the higher temperatures and pH, starch damage was higher. At low temperature and pH, the percentage of starch recovery was low although the starch damaged was less. By increasing the steeping time, the starch recovery was increased. By taking all factors into consideration, 9.0pH at 30oC was selected as a best rice starch extraction condition for 18 hours steeping time. In case of 22 hours steeping time, 8.5pH at 35oC was selected best rice starch extraction condition.

Index Terms— Extraction of Starch, Steeping Time, Rice, Temperature and pH

—————————— ——————————

Rice is one of the leading food crops in the world, and worldwide annual production of milled rice is about 380 mil- lion metric tons. Rice is the staple diet and 50% of the world population, mostly in Asian countries it provides 35-59% of energy consumed. One of the solutions to increase the eco- nomic value of low quality rice is to convert it into the rice starch. The rice starch is known as a food additive to give slower-digesting effect. Athletes like marathon runners build their endurance by eating the food containing the rice starch to keep a steady flow during the food digestion in the stomach. The rice starch is also added to the baby formula to thicken it for helping the baby with a fuller feel and a longer digestion process. The rice starch is a unique starch among available commercial starches because of its small granule size and its hypoallergenic residual protein [1] (Schoch, 1967). However, the rice starch at present time is less favorable than other starches due its higher production cost. In food industry, it is utilized in different type of products such as starch hydroly- sates, glucose syrups fructose, maltodextrin derivatives or cy- clodextrins by chemically and enzymatically processed.

————————————————

![]()

• Bushra Isfaq is currently working as Research Officer at Food Technology

Section, Post Harvest Research Centre in Ayub Agricultural Resaerch In- stitute, Faisalabad, Pakistan, PH-+92-03338984372. Email:

• Muhammad Iqbal is currently working as Research Officer at Oil Seeds

Research Institute in Ayub Agricultural Resaerch Institute, Faisalabad, Pakistan, PH-+92-03338723050. Email: miqbalahmad85@gmail.com

Starch is a polymer of glucose and two types of glu- cose polymers are present in it like amylose and amylopectin [2, 3] (Li and Yeh, 2001 and Singh et al. 2003). These polymers have different structures and properties. The molecular weight of amylose is approximately 105 [4] (Juliano, 2003). Amylose is formed from 500 to 20000 glucose monomer. The molecular weight of starch polymers varies from plant to plant. Amylo- pectin molecular weight varies from 50 x 106 to 500 x 106, and amylose ranges from 1600 to 106. Common starches typically contain 25-35% amylose and 65-75% amylopectin, the ratio between amylose to amylopectin determines the characteristic of the starch. The more amylopectin in the starch, the sticker the starch will be. Rice starch contains 17% amylase and 83% amylopectin.

The shape and size of starch granules depend on the

source and the ambient condition of the growing area. Starch shapes have the forms of globular, ellipse, oval, lenticular and amorph. The sizes of starch granules are about 3 to 30μm for cereals about 10 to 100μm for tubers.

When granular starch is mixed with water, the starch

will be gelatinized. In the gelatinizing process, the starch molecules swell irreversibly. Water can penetrate into a starch molecule depending on the temperature. The increase of the temperature leads to the increase of the kinetic energy to be greater than the bond energy within the starch molecules. At the temperature of 20 – 30ºC, starch granules start absorbing the water to produce large starch granules. When the temperature reaches 40 to 50ºC, the water content in the starch will be excessive and the water transfer occurs reversibly. The starch granules are dense and insoluble in cold water. In order to dissolve the starch a granule, heat has to be applied.

Starch can be hydrolyzed into smaller molecule using

two methods. They are acid hydrolysis and enzyme hydroly-

sis. Hydrolysis enzyme can be processed in a non-extreme condition (pH and temperature).

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 6, June-2014 888

ISSN 2229-5518

Starch promotes the physiochemical changes during the food process. This event is determined by the starch-water interacttion, fat content, time, temperature, mechanical force, and pH. Starch has stable characteristics in liquid and other solvent [5] (Bindar, 2013). This characteristic is very suitable for preventing crystallization in the food product especially ice cream and others frozen products. Based on this characteristic, starch can form a good texture in many food products.

Rice usually contains 80-90% starch. It becomes one of

many potential sources of starch. Unfortunately, the infor- mation about the production process of rice starch from low- quality rice is limited. This research is then motivated by this reason especially to utilize the KSK-133 low grade Pakistani broken rice as the raw material to produce the rice starch.

There are several methods for producing rice-starch. They are alkaline-steeping method [6] (Cristina et al. 2008), high-intensity ultrasound and surfactant [7] (Wang and Wang,

2004), Guraya method [8] (Guraya and James, 2002), protease digestion [9, 10] (Zheng and Bhatty, 1998; Juliano, 1991) and alkaline-protease methods [11] (Lumdubwong and Seib, 2000). These methods show different characteristic. Also shows dif- ferent extraction efficiencies and functional properties. The alkaline steeping-method [12] (Yang et al. 1984) is the simplest method for starch production. This method is applied easily in a simple apparatus system. The advantage of this method is high purity of produced starch. At Ideal extraction conditions, extracted components have little or negligible structural changes while in case of rice starch depolymerization or change (damage) to its crystalline phase is undesirable. The detail mechanism of rice protein extraction into alkaline solu- tion has not yet been clearly defined. The mechanism is prob- ably based on the protein solubilization in the alkaline solu- tion without chemical changes. The extraction process contin- ues and stops when the equilibrium is reached. This assump- tion is based on the protein extraction process in the animal tissue [13] (Alpert and Schmerr, 2000). The soluble protein can be isolated effectively.

The present study is carried out to enhance the processing conditions for the extraction of starch. There is dire need in our country to focus on the other crops for the extraction of starch rather than maize which will be helpful to meet the demands of industries and economical.

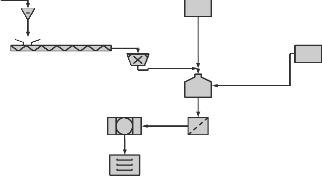

tion cup, filter paper, pH meter and thermometer. Firstly took the rice sample, and then grinded the rice with the help of grinder. Then steeping solution prepared in a steep. Here took the grinded rice flour sample with distilled water. Then set the pH by using the 0.1M caustic soda solutions. During washing kept the flour to water ratio 1:3. During extraction it was 1:10. From Protection of bacteria and its growth used 0.01% sodium metabisulphite weight to volume ratio. The steep solution was continually circulated. For this purpose, steep’s pump was operated at 2800 rpm for 18 and 22 hrs individually.

For the protein recovery, the peak lipid film was re-

moved from the surface. Unbonded protein was separated

with the help of water. After every two hours the pH and tem- perature of the steep solution was checked and set to the test- ing conditions such as temperature and pH.pH was set with the help of 0.01M caustic solutions.

Primary filtration was done after every two hours. For

primary filtration, 325 mesh Screen was used and this step was called primary filtration. When poured the steep solution on the screen, the tiny particles passed from screen. Then over size particles again sent back to the steep for further recovery of starch. But test conditions were kept same.

The extracted starch was collected and given resi- dence time for 90min in a beaker. The separated residue was collected and recycled in a steep. The recovered starch was again washed with water in the ratio of 1:3 respectively. At this time all the remaining residue was separated for protein re- covery. The separated starch was isolated onto a filter paper. Then this filter paper was fixed on a vacuum flask for vacuum filtration for removal of water. This step was called vacuum filtration. All the partially wet recovered starch was collected on the filter paper. Then it was kept in atmosphere for air- dried at room temperature for 48 hrs.

Then dried starch weight was measured. This weight

was compared with the initial weight of starch which was pre- sent in the rice and calculated the starch recovery (%).

This trial performed for each temperature and pH for

both steeping times 18 and 22 Hrs.

Raw material

0.1M NaOH

was procured from Rice Research Institute Kala Shah Kako

Lahore Pakistan.

Rice Flour

Grinding

T=22~40°C

pH=7~9.5

Steeping Time=18&22 Hrs

Steeping

Distilled Water

Vacuum Filtration

Drying

Primary Filtration

primary filtration, (5) washing with water, (6) Vacuum filtra-

tion (7) drying the starch cake. The production apparatus are grinder, steep, 325 mesh screen, vacuum flask, beaker, filtra-

Process Diagram

![]()

Figure-1: Process Flow Sheet

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 6, June-2014 889

ISSN 2229-5518

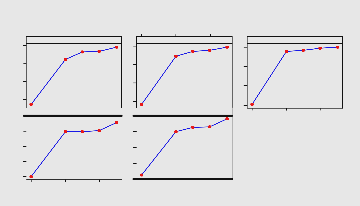

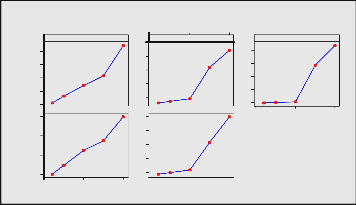

The effect of temperature and pH to starch content at various steeping time duration are shown by Figures. The quality of produced starch is indicated by higher starch con- tent.

Table-1: Steeping Time Was 18 Hrs, In Case of pH & Starch Recovery

(%)

Table-2: Steeping Time Was 22 Hrs, In Case of pH & Starch Recov ery (%)

Temp. (oC) | 22 | 25 | 30 | 35 | 40 |

pH | Starch Recovery (%) | ||||

7 | 76.3 | 77.27 | 78.9 | 80.3 | 84.9 |

8 | 77.35 | 77.51 | 77.8 | 81.3 | 83.2 |

8.5 | 79.95 | 80 | 80.1 | 85.7 | 88.8 |

9 | 80 | 81.83 | 84.975 | 87.03 | 92 |

9.5 | 84.75 | 85.03 | 85.5 | 90.45 | 95 |

Steeping Time Was 18 Hrs. In Case of pH & Starch Recovery %age

7 8 9

T emperature 22C

84

82

80

78

76

T emperature 25C T emperature 30C

86 86

84 84

82 82

80 80

78

78

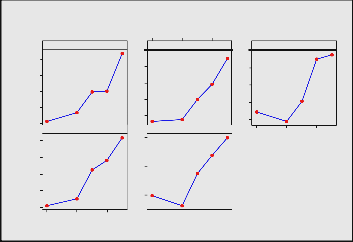

Fig-3:pH & Starch Recovery % at Different Temperatures (S.T=22hrs)

The fig.3 showed the increasing trend at all tempera-

90.0

87.5

85.0

82.5

80.0

T emperature 35C T emperature 40C

95

90

85

7 8 9

tures and pH. The maximum starch recovery has been achieved 95.4% at 9.5pH. This case is also similar to the above case, temperature was kept constant and pH changed. Recov- ery increased with increased in pH and temperature. The min-

7 8 9

pH

Fig-2: pH & Starch Recovery % at Different Temperatures (S.T=18hrs)

Fig.2 depicted that temperature was kept constant and pH changed, kept the steeping time 18 hours. Recovery increased with increased in pH and temperature. From this figure it is cleared that pH and temperature are directly pro- portional with each other. Minimum starch recovery has been achieved 76.3% at 7.0pH and maximum recovery has been achieved at 9.5pH which was 95.0%.So, it is concluded from present study that higher the pH, the higher was the % starch recovered.

imum starch recovery has been achieved 73.6% at 7.0pH and

maximum recovery has been achieved at 9.5pH which was

95.4%. The longer the steeping time duration, the higher the

starch content that is produced. This applies to the NaOH con- centration at 0.1M. High pH could leads to undesirable protein modification i.e. molecular cross linkage and rearrangements resulting in the formation of toxic compound. On the other side at the high temperature starch gelatinization is started.

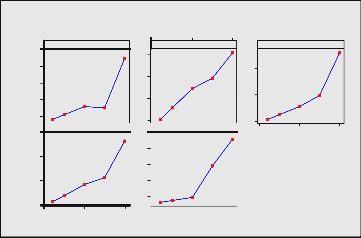

Third case is similar to first case but the only differ- ence is analyzed the effect of different temperatures from 22 to

40oC on starch recovery %age at constant pH and kept the

steeping time was 18hrs.

In second case only steeping time was changed

which was 22hrs steeping time and analyzed the same effect of different pHs from 7 to 9.5 on starch recovery %age at constant temperature.

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 6, June-2014 890

ISSN 2229-5518

Table-3: Steeping Time Was 18 Hrs, In Case of Temp. & Starch Re- covery (%)

Table-4: Steeping Time Was 22 Hrs, In Case of Temp. & Starch Recov- ery (%)

pH | 7 | 8 | 8.5 | 9 | 9.5 |

Temp. (oC) | Starch Recovery (%) | ||||

22 | 76.3 | 77.35 | 79.95 | 80 | 84.75 |

25 | 77.27 | 77.51 | 80 | 81.83 | 85.03 |

30 | 78.9 | 77.8 | 80.1 | 84.975 | 85.5 |

35 | 80.3 | 81.3 | 85.7 | 87.03 | 90.45 |

40 | 84.9 | 83.2 | 88.8 | 92 | 95 |

Steeping Time Was 18 Hrs. In Case of Temp. & Starch Recovery %age.

Steeping Time Was 22 Hrs. In Case of Temp. & Starch Recovery %age

20 30 40

20 30 40

pH 7

pH 8 pH 8.5

pH 7

84

82

80

78

76

84.0

82.5

81.0

79.5

78.0

pH 8 pH 8.5 82 92

88 80 92

86 90

78

84

90

82 76 88

80 74

pH 9 pH 9.5

92 95.0

92.5

88

90.0

84

87.5

80 85.0

20 30 40

pH 9

94

92

90

86

96.0

94.5

93.0

91.5

pH 9.5

88

20 30 40

20 30

40

Temperature(C)

88

20 30

90.0

40

Fig-4: Temperature& Starch Recovery % at Different pH (S.T=18hrs)

Starch contents in the 0.1 M NaOH extracts at various

extraction temperatures are shown in Fig.4 By increasing tem- perature from 22 to 40°C, a proportional increase in the ex- tracted starch content was observed. The maximum starch recovery had been achieved at 40oC. Recovery increased with increased in pH and temperature. The minimum starch recov- ery had been achieved at 22oC.

In starch the bonds exist between amylopectin in the

crystalline regions and amylose in the amorphous re-

gions.Temperature directs the swelling process along the amorphous regions and since the crystalline regions do not expand, stress increases at the interface between the crystalline and amorphous regions. Thus, at a certain point in the swell- ing process the crystalline regions are rapidly and irrevers- ibly broken and gelatinization is initiated. At excess water con- tent, onset of the gelatinization usually occurs above 40OC.

Forth case is also similar to second case but the only

difference is analyzed the effect of different temperatures from

22 to 40oC on starch recovery %age at constant pH and kept

the steeping time was 22hrs.

Temperature(C)

Fig-5: Temperature & Starch Recovery % at Different pH (S.T=22hrs)

Fig.5 represent that the maximum starch recovery had been achieved at 40oC. It was found that the extraction tem- perature did not affect the residual protein content when the temperature was higher than 25°C although the difference between 20°C and 25°C was found significant. By raising the temperature, the adverse effect might be related to the changes in the starch structure induced by heat and alkali. Starch granules are readily swollen and gelatinized by alkali and heat. It was expected that the granule-bound proteins were more difficult to remove from the swollen granules because of susceptibility to the alkaline solutions or other hydrogen bond breaking agents so, starch loss may occur during protein ex- traction with these agents. Minimizing starch loss is desirable not only to enhance the starch content but also to lessen the organic waste occurring during the starch isolation. The posi- tive effect of temperature on the starch solubility appeared statistically significant in all extraction steps. Heating is not recommendable because it does not progress protein extrac- tion but increases starch loss.

The longer the steeping time duration, the higher the

starch content that is produced. This applies to the NaOH con- centration at 0.1M. Without the protease enzyme, the starch content is always higher for higher steeping time duration.

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 6, June-2014 891

ISSN 2229-5518

The protein content is the second response variable to determine the quality of the rice starch. All the trials have less protein content. The protein content must be kept as low as possible to meet the specification of high quality rice starch. High content of protein could spoil the sticky and gristly char- acteristic of the rice starch.

used for gelatinizing process. These are viscosity and gel strengthens. This process is based on the temperature, steep- ing time and pH. In this work, the gelatinizing analysis is based on a visual observation due to the difficulty in measur- ing the gelatinizing viscosity. When the gelatinizing process occurs, the starch forms a gel condition due to high viscosity. A good quality of starch is identified by a homogeneous gel. When the gelatinizing condition is achieved, there is no ap- pearance on any tiny granule. For KSK-133 rice flour, the color

is white with some yellow shadow and tiny granules were

found in some part of the gel. At 40oC the starch’s color ap- pearance is dominantly white and transparent at 22 hours steeping time.

the variables such as temperature, steeping time and pH. The

optimization objective is to have the starch content as high as possible with good quality.

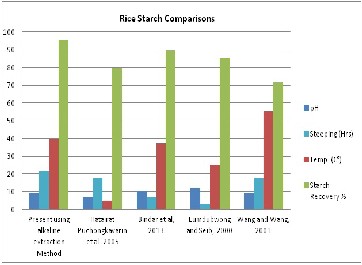

The quality of produced starch is indicated by higher starch content. The starch content increases with temperature and pH. According to the data obtained above, the optimum condition to produce a high quality rice starch from the raw material of low low quality Pakistani broken rice with the al- kaline method at 40oC and at 9.5pH, kept the steeping time 22 hours and extracted starch contents was 95.4%.

literatures about the rice starch production for different meth- ods. Each of them gives different results. These differences are caused by some factors, such as rice flour content, rice quality, pre-treatment, production method, separation method and others.

Table-5: Rice Starch Comparisons

The produced starch in this work contains 95.0 to

95.4% of starch content. This result is higher by comparing to others. This phenomenon may be caused by the differences of material and with no pretreatment. The present work uses the Pakistani broken rice that contains higher protein and impuri- ties while the other researchers used selected and pre-treated rice.

1. It is concluded that alkaline method was successfully im- plemented to produce the better quality rice starch from broken rice KSK-133.

2. Maximum starch recovery has been achieved from 85 to

95% for all temperatures at 9.5pH for steeping times 18 &

22 hrs.

3. In 22 hrs steeping time, the starch recoveries lower than 18

hrs steeping time, at all temperatures and at 7.0pH.

4. At the higher temperatures and pH, starch damage was higher.

5. At low temperature and pH, the percentage of starch re- covery was low although the starch damaged was less.

6. Starch recovery was increased by increasing the steeping

time.

7. Maximum recovery of starch from KSK-133 rice has been

achieved up to 95.4%.

8. Best extraction conditions in case of 18 hrs steeping time

at 30oC and 9.0pH has been achieved.

9. Best extraction conditions in case of 22 hrs steeping time at 35oC and 8.5pH has been achieved.

10. The starch extractability by raising the temperature was not recommendable because %recovery increase was mi- nor, and loss became significant.

11. The starch digestibility may be affected by structural fea- tures, interactions with other components of the endo- sperm and with processing conditions.

12. Further advancements are needed to produce high quality

rice starch that meets the international standard.

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 6, June-2014 892

ISSN 2229-5518

The valuable inputs from my colleagues and friends during the compilation of this review are highly appreciated. References

[1] T.J. Schoch, “Properties and uses of rice starc”, In Whister, R. L. and Paschall, E. F. (Eds.), Starch Chemistry and Technology, pp. 79–86, 1967. [2] J.Y. Li and A.I. Yeh, “Relationships between thermal rheological characteristics and swelling power for various starches”, J. Food Engineer- ing, volume. 50, pp. 141-148, 2001.

[3] N. Singh, J. Singh, L. Kaur, S.N. Singh and G.B. Singh, “Morpho- logical, thermal and rheological properties of starches from different botani- cal sources”, Food Chem, volume. 81, pp. 219-231,2003.

[4] B.O. Juliano, Rice in Cabalerro, B. (Ed). Encyclopedia of Food Science and Nutrition, pp. 4995-5001, 2003.

[5] Y. Bindar, A. Efan and S. Rahmi “Sodium hydroxide (NaOH) con- centration and steeping time duration effects on starch production from dry milled low quality rice IR 64 grade 3 flour using alkaline-protease enzyme digestion method”, International Food Research Journal,volume.

20, pp. 1353-1358, 2013.

[6] M. R. Cristina and M. Cristina, “Gluten Free Cereal Product and

Beverages: Rice”, Food Science and Technology, Chapter#. 4, pp. 81-102,

2008.

[7] L.Wang and Y.J.Wang, “Application of high intensity ultrasound and surfactants in rice starch isolation”, Cereal Chemistry, volume. 8, pp.

140-144, 2004.

[8] H.S. Guraya and C. James, “Deagglomeration of rice starch-protein aggregates by high-pressure homogenization”, Starch/Stärke, volume. 54, pp. 108–116, 2002.

[9] G.H. Zheng and R.S. Bhatty, ”Enzyme-assisted wet separation of starch from other seed components of hull-less barley”, Cereal Chemistry, volume. 75, pp. 247–250, 1998.

[10] B.O. Juliano, “Rice starch: Production, properties and wheat flours”, Journal of Cereal Science, volume. 13, pp. 145-152, 1991.

[11] N. Lumdubwong and P.A, Seib, Rice starch isolation by alkaline protease digestion of wet-milled rice flour”, Journal of Cereal Science, volume. 31, pp. 63–74, 2000.

[12] C. Yang, H.M. Lai and C. Y. Lii, “The modified alkaline steeping method for the isolation of rice starch”, Food Science, volume. 11, pp. 158–

162, 1984.

[13] A. J. Alpert and M.J. Schmerr, “Method and kit for Extracting Prion Protein, World Intellectual Property Organization, Patent# PCT/US2000/000457, 2000.

[14] H. Puchongkavarin, V.S. Saiyavit and W.Bergthaller, “compara-

tive study of pilot scale rice starch production by an alkaline and an enzy- matic process” Starch/Stärke, volume. 57, pp. 134–144, 2005.

[15] L. Wang and Y.J. Wang, “Comparison of protease digestion at neutral pH with alkaline steeping method for rice starch isolation”, Cereal Chemistry, volume. 78, pp. 690–692, 2001.

IJSER © 2014 http://www.ijser.org