International Journal of Scientific & Engineering Research, Volume 5, Issue 5, May-2014

ISSN 2229-5518

825

Mst. Murshida Khatun

Daffodil International University, Dhaka, Bangladesh

Email: murshida@daffodilvarsity.edu.bd, murshidatex05@gmail.com

Index Terms- time study, motion study, productivity and allowance.

A work measurement technique for recording the times and rates of working for the elements within specific conditions, and for analyzing the data so as to determine the time necessary

for carrying out a job at a defined level of performance. Time study evolved from the work of Taylor and was the original work measurement technique [6]. Motion study is a technique of analyzing the body motions employed in doing a task in order to eliminate or reduce ineffective movements and facilitates effective movements. By using motion study and the principles of motion economy the task is redesigned to be more effective and less time consuming [1]. Productivity can be defined as the ratio of output in a period of time to the input in the same period time. Productivity can thus be measured as:

Output (In period of time) Productivity

Input (In the same period)

In simple terms productivity is the quantitative relationship between what we produce

(output) and the resources (inputs) which we used [4].

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 5, May-2014

ISSN 2229-5518

826

TURAG GARMENTS & HOSIERY MILLS LTD.

IE & PLANNING DPT.

Total

Manpower

(bottom)

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 5, May-2014

ISSN 2229-5518

827

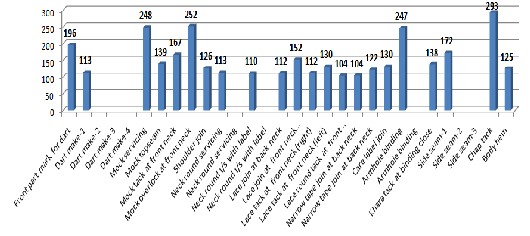

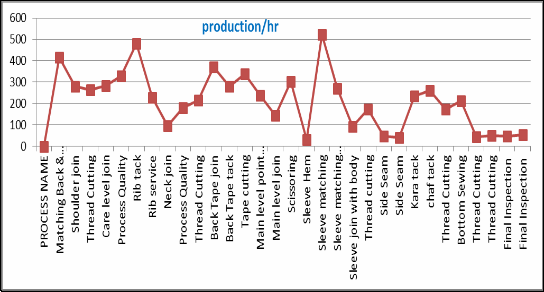

From the graph it is clear that for different parts production different time is needed. Most time is needed for sleeve hem joining and lowest time is needed for thread cutting and in side seam.

Standard minute value is the standard time, to complete any given task by using best possible methods at standard level of performance. To estimate SMV we have to analyze the garment

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 5, May-2014

ISSN 2229-5518

828

carefully and check different factors that affect the SMV. SMV of a product varies according to the work content or simply according to number of operations, length of seams, fabric types, stitching accuracy needed, sewing technology to be used etc

Standard minutes (SMV) of few basic products have been listed down with its SMV range according to work content variation. In actual cases garment SMV may go outside of the limit

depending the above factors.

Sl.no | products | SMV(Average) | SMV(Range) |

1 | Neck T-shirt | 8 | 6 to 12 |

2 | Polo shirt | 15 | 10 to 20 |

3 | Pormal full sleeve shirt | 21 | 17 to 25 |

4 | Pormal Trouser | 35 | 25 to 40 |

5 | Sweat shirt(Hooded) | 45 | 27 to 50 |

6 | jacket(suit) | 95 | 75 to 135 |

From the above table it is seen that various product has various standard minute value. SMV

range is higher for jacket and lower for neck T-shirt.

Before it is possible to complete and issue that standard time for a job, it is necessary to add to the basic time certain allowances.

The reason for adding these allowances is that the work study engineer has only been considering the productive work of the operator and has not taken into account the periods of rest that are required by the operator to enable the operator to recover from the energy expended, nor the time that he/she needs to allow attention to personal needs.

To get the standard time, a proper allowance must be added consisting the working conditions. While deciding the quantum (generally in terms of percentage) of allowance to be added to the normal time, following types of allowance are considered:

1. Machine allowances

2. Relaxation allowance

3. Interference allowance

4. Process allowance

5. Special allowance

• Thread cone or tube change

• Thread and needle breakage

• Adjusting tension

• Small problems in machine

The following chart shows the allowance value for different kind of machines.

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 5, May-2014

ISSN 2229-5518

829

Table 3: Machine allowances

For different machine allowance is varied according to machine requirements.

People are not machines and they need to go the toilet, scratch, blow their nose, etc.

Relaxation and fatigue allowances are provided to give the operator/ worker the opportunity to recover from the effort of doing his/her work, and to allow for attention to personal needs. The relaxation and fatigue allowance is given to every operation. Recommended allowances for personal and fatigue allowances in the sewing trade are set at 11% for sitting jobs and

13% for standing.

When one worker is attending more than one machine, then interference is the time for which

one or more machine units remain idle while the operator is occupied with the work on other machine units. The allowance provided to compensate this idleness due to interference is known as interference allowance.

This is an allowance provided to compensate for enforced idleness during a process. This includes loss of time due to:

(i) no work

(ii) Power failure

(iii) Faulty material

(iv) Faulty tools or equipments

A contingency allowance should not be greater than 5% and should only be given in cases

where the work study officer is absolutely satisfied that they are justified. The contingency allowances should be expressed as a percentage of the basic time.

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 5, May-2014

ISSN 2229-5518

830

These allowances are decided as a policy matter of management. These are allowed for

activities which are normally not a part of the operation cycle bur are essential for satisfactory performance of work. These include for the following items:

(i) Start up (ii) Cleaning (iii) Shut down (iv) Set up

(v) Dismantling allowance

(vi) Change over

(vii) Reject allowance

(viii) Excess work allowance

(ix) Learning allowance

(x) Training allowance

(xi) Implementation allowance

(xii) Small batch allowance

(xiii) Tool changing and regrinding

The Goals of Motion Study

(i)Improvement

(ii) Planning / Scheduling (Cost) (iii)Safety

Operators use their body for different operations, and spend their maximum time. The motion time is long but sewing time is short. So, body movement is classified by 5 divisions. They are as below:

1. Knuckle: only finger is used for this movement

2. Wrist: using hand and finger

3. Elbow: For arms, hand and finger.

4. Shoulder: Upper arm, forearm hand and finger.

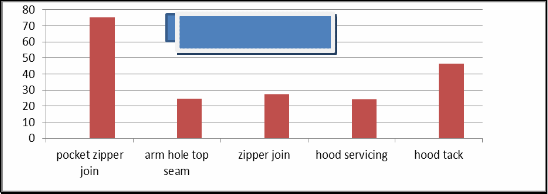

sl.no | operation | cycle time(sec) | avg. | ||||

sl.no | operation | 1 | 2 | 3 | 4 | 5 | avg. |

1 | pocket zipper join | 67.91 | 68.11 | 81.50 | 65.13 | 93.13 | 75.13 |

2 | arm hole top seam | 20.73 | 27.17 | 24.93 | 26.18 | 23.13 | 24.42 |

3 | zipper join | 29.23 | 24.34 | 23.12 | 32.23 | 25.13 | 27.45 |

4 | hood servicing | 23.24 | 22.34 | 25.23 | 28.27 | 22.18 | 24.10 |

5 | hood tack | 44.52 | 46.34 | 48.17 | 46.23 | 43.12 | 46.56 |

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 5, May-2014

ISSN 2229-5518

831

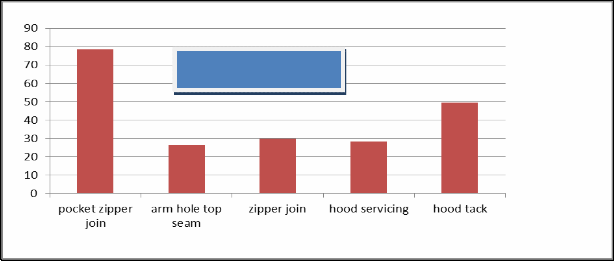

Operation Vs Time

sl.no | operation name | cycle time/sec | Aveg. | ||||

sl.no | operation name | 1 | 2 | 3 | 4 | 5 | Aveg. |

1 | pocket zipper join | 68.75 | 70.23 | 83.50 | 67.45 | 97.73 | 78.54 |

2 | arm hole top seam | 22.34 | 31.17 | 26.86 | 25.71 | 26.13 | 26.33 |

3 | zipper join | 31.12 | 26.72 | 25.17 | 34.17 | 27.33 | 29.73 |

4 | hood servicing | 25.33 | 24.52 | 27.23 | 30.23 | 24.12 | 28.34 |

5 | hood tack | 46.23 | 48.23 | 50.23 | 46.65 | 44.75 | 49.35 |

Operation Vs Time

The above the figure represents the relation between operation and time. It is seen that highest time is needed for pocket zipper joining and lowest time is needed for arm hole top

seam.

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 5, May-2014

ISSN 2229-5518

832

From the above discussion, it is clear that a standard can be maintained in the garment sector to get the maximum production by using the time properly. Different time is needed to sew the different parts of a garment. As a result time variation is must. Since garments are made with the help of different operator, time limitation must be given to achieve the target production. To set a standard target for different product time and motion study is mandatory.

By making the time and motion study target production can be achieved. As a result shipment of a particular product can be made in exact time and there would be no delay to get the payment to the seller.

[1] www.google.com, Wikipedia, of Industrial Engineering (retrieved: JULY 5, 2013 ) [2] www.google.com INDUSTRIAL ENGINEERING AND ENGINEERING

MANAGEMENT IN AUSTRALIA By Professor John W H Price PhD, FIEAust Mechanical

Engineering Department, Monash University, Australia.

[3] www.google.com , industrial-engineering-lecture-02 ppt,

[4] Zeleny,M.: The Innovation Factory: On the Relationship Between Management Systems, Knowledge Management and Production of Innovations. Innovations 2005, Zilina 2005

[5] Guidelines for Industrial Engineering, KSA Technopak.

[6] Method of analyzing the actual status 4-Time Study Chapter two (page E-1, E-10) and

Chapter three Production Design (page F-1, 2, 3, 6, 8, 9, 12, 13)

Seminar on Sewing Production Control, Textbook on the Management Development Course, ASSOCIATION FOR OVERSEAS TECHNICALE SCHOLARSHIP (AOTS), Sewing Research Institute, JUKI Corporation.

[7] http://www.lcmibd.com/industrialengineering.htm

[8] http://wiki.answers.com/Q/Industrial_engineering_work_study_in_garments

[9] http://www.onlineclothingstudy.com/2012/09/-how-to-calculate-efficiency-of.html http://wiki.answers.com/Q/Industrial_engineering_work_study_in_garments

[1] Production planning, control & Industrial management.

(By Dr. KC. Jain) [2] Industrial Engineering in Apparel Production

(By V Ramesh Babu)

[3] Industrial Engineering and Management

(By C.Natha Muhi Reddy)

[4]Industrial Engineering and Engineering Management

(By professor john W H)

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 5, May-2014

ISSN 2229-5518

833

IJSER © 2014 http:1/www.ijser.org