The fundamental architecture of the WSN sensor node consists

International Journal of Scientific & Engineering Research, Volume 6, Issue 4, April-2015 558

ISSN 2229-5518

Development of wireless sensor network system for LPG gas leakage detection system

T.H.Mujawar*1, V.D.Bachuwar*2, M.S. Kasbe*3, A.D. Shaligram** and L.P. Deshmukh*4.

Abstract— Leakage of a gas in any sector may cause many health issues and hence in the work places it is to be cautioned against such disaster hap- penings by implementing a safety system that can make an early alert to the users. This paper describes the development of wi reless sensor network for LPG gas leakage detection. The proposed design includes: an Arduino Nano microcontroller, gas sensor and a XBee. The sensor node will detect a minute concentration of the gas according to the voltage output of a sensor and also collects the gas leakage data thereby locating the specific area of the sensor node. XBee sends the data from gas sensor to the monitoring system that is displayed on LabVIEW GUI. A GSM module was as a communi- cation tool between the microcontroller unit and mobile phone unit. The system could be installed at any remote place and could be controlled by any mobile phone supporting the SMS service. The reliability and productivity of the system are the key concerns and influence the design and development choices for the system in terms of the hardware and software designs.

Index Terms— Arduino, Gas leakage detection, GSM shield,Gas leakage monitoring,RSSI, LabVIEW, XBee.

—————————— ——————————

Natural gases such as liquefied petroleum gas (LPG) are wide- ly used in industries. It is certainly possible that the gases may leak and the system needs to be real time monitored. This pa- per presents design and development of a wireless gas leakage monitoring system by using the Arduino and XBee.

The system is configured in star type topology with devices

and sensors in it and then controls all the devices through a gateway node with XBee network, and takes safety measures to protect against serious risk. The proposed system uses XBee as a wireless device, sensors and Arduino controller that not only increases the system performance and but provides safe- ty measures also.

In actual, the work was carried out using Arduino nano board,

MQ-2/MQ-6 gas sensor, XBee and a GSM module. The sensor has excellent sensitivity combined with a quick response time at low cost. Under gas leaked condition message to the author- ized person or family member using Arduino GSM shield is sent automatically.

Traditionally, gas leakage detection is monitored by a wired sensor network, wherein power requirements and mainte- nance cost are significantly high “[1]”.To overcome the limita- tions of traditional system wireless sensor network is the best choice. The high power requirement of wired sensor network can be made simpler using WSN technology that uses differ- ent protocol standards for short range wireless communica- tion like Bluetooth, WI-Fi and Zigbee. Nowadays, Zigbee is widely used in gas leakage monitoring applications for real

time monitoring of the threat area.

The monitoring of the proposed design is done through Lab- VIEW “[2]”, [3]”. Also, GUI created using LabVIEW tool is more interactive, facile and effective compared to the reported methods.

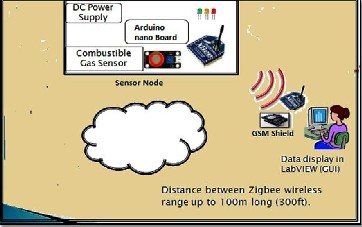

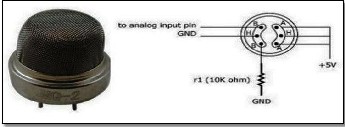

based on a small-scale and low cost device those achieve Pro-

cessing, storing, sensing and communicating. The basic block diagram of the proposed system is shown in figure 1.

Fig. 1. Block diagram of a wireless gas sensing s system

The fundamental architecture of the WSN sensor node consists

IJSER © 2015

International Journal of Scientific & Engineering Research, Volume 6, Issue 4, April-2015 559

ISSN 2229-5518

of a sensor unit, an analog signal conditioning unit, a compu- tation unit and a wireless communication unit. The WSN nodes were designed using these architectural tools.

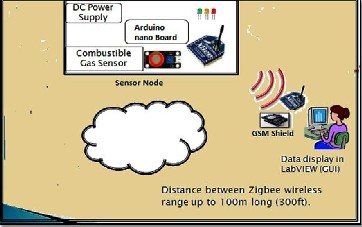

Figure 2 shows a node prototype which is an Arduino board

that serves as a sensor node.

Fig.2 wireless sensor node

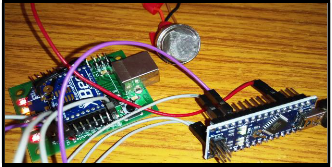

The sensitive material used in MQ-2 gas sensor is tin oxide (SnO2), which has lower conductivity in a clean air medium. When the target LPG leak is detected, the sensor ’s conductivi- ty rises and increases proportionately as the extent of gas leakage increases. The detection range of MQ-2 gas sensor is

300-5000 ppm”[4]” and has fast response time and is a low powered device (5V). This sensor has different resistance value in different concentration.

Fig.3.MQ-2gas sensor

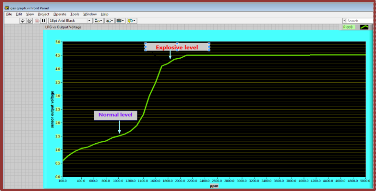

The Calibration of MQ-2 gas sensor was done in a gas cham- ber using a standard medical syringe. The gas concentration in ppm was varied and corresponding output voltages were not- ed. This is shown in fig 5.![]()

Fig.4. Sensor calibration unit

The voltage ranges for LPG gas concentration corresponding to various levels were measured and these are given in the

following Table 1.

Gas concentration in ppm | voltage range in volts |

≤400PPM | ≤1.5V (normal level) |

400PPM – 800PPM (lower exposure limit) | ≥1.5V TO _ ≤4.2V (low level) |

≥800PPM (upper exposure limit) | ≥4.2V (explosive level) |

TABLE 1. THRESHOLD LEVEL OF GAS SENSOR

Fig.5.Graph on sensor output voltage Vs ppm

The fig. 5. Implies that if the gas concentration is increased above the normal threshold level (400ppm), the system acti- vates and gives alert to the user.

An Arduino UNO was used as a microcontroller for gateway node and an Arduino nano as a microcontroller for sensor nodes. These devices are considered as an open source elec- tronic platform based on flexible hardware and software. Windows, Macintosh and Linux operating system supported the Arduino software based on C programming language and can be expanded through C++ libraries” [5]”.

One of the microcontroller board used was an Arduino UNO

based on the ATMEL microcontroller (ATmega328). It has 14 digital input/output pins (of which 6 can be used as PWM outputs), 6 analog inputs, a 16 MHz crystal oscillator, a USB connection, a power jack, an ICSP header, and a reset button

[11]. It contains everything needed to support the microcon-

IJSER © 2015

International Journal of Scientific & Engineering Research, Volume 6, Issue 4, April-2015 560

ISSN 2229-5518

troller; simply connect it to a computer with a USB cable or power it with an AC-to-DC adapter or battery to get started. Arduino nano is small, complete and breadboard-friendly board based on ATMEGA 328 and works with Mini-B USB cable instead of standard one. It has 14 digital input or output pins (of which 6 can be used as PWM outputs), 6 analog in- puts and a power jack, an ICSP header, and a reset button [5-6] having number of facilities for communication with the com- puter.

ZigBee is a set of specifications created specifically for control and sensor networks. Built on IEEE 802.15.4, the standard for low data rate wireless personal area networks (WPANs). It is a low latency, low data rate, low cost, and low energy consump- tion device. IEEE standard 802.15.4, which defines the physical layer (PHY) and media access control (MAC) for low-rate WPANs, restricts the data rate to 250 kbps in the global 2.4- GHz Industrial, Scientific, Medical (ISM) band, while also specifies low power consumption and cost. The Zigbee is a program using X-CTU software.

The Arduino GSM shield allows an Arduino board to connect to the internet, make/receive voice calls and send/receive SMS messages. The shield uses a radio modem M10 by Quectel and it is possible to communicate with the board using AT com- mands. The shield establishes for software serial communica- tion with the M10. Pin 2 is connected to the M10’s TX pin and pin 3 to its RX pin. The modem's PWRKEY pin is connected to Arduino pin 7.

The M10 is a Quad-band GSM/GPRS modem that works at frequencies typically, at GSM 850MHz, GSM 900MHz, DCS

1800MHz and PCS 1900MHz. It supports TCP/UDP and HTTP protocols through a GPRS connection. GPRS data downlink and uplink transfer maximum speed is 85.6 kbps. The modem can pull up to 2A of current at peak usage, which can occur during data transmission. This current is provided through

the capacitor on the board's surface.

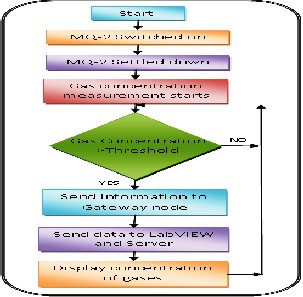

The sensor node sends the output data from gas sensor to the gateway node with the help of XBee transceiver. The Lab- VIEW tool is provided for interfacing the hardware and soft- ware parts. Then based on the threshold value set, the sensor will keep on sensing the gas concentration, which is moni-

tored it on LabVIEW as shown in Fig. 6. Fig.6 is a flowchart for a wireless gas leakage monitoring system.

Fig 6. Flowchart for wireless gas leakage monitoring system.

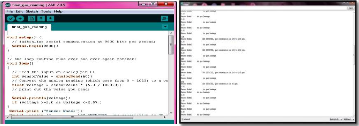

In this wireless gas leak detection system, the sensor is con- nected to an analog port of the Arduino nano board (sensor nodes)” [7]”, which measures various gas concentration at ppm level and sends them to the Arduino UNO board (Gate- way Node).The status of sensor nodes where the leakage exists is shown in serial monitor window in a gateway node as be- low (fig.7)

.

Fig. 7.Arduino programming for MQ-2

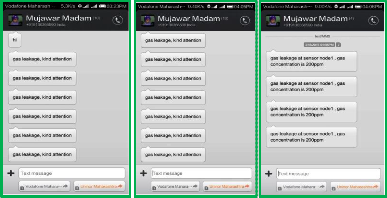

The present system was placed inside a room where a gas cyl- inder was placed and leak detection was noted. The gas leak- age response can be obtained and send to the mobile users saved in Arduino GSM shield and also displayed on the moni- toring system.

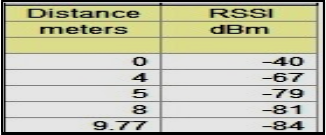

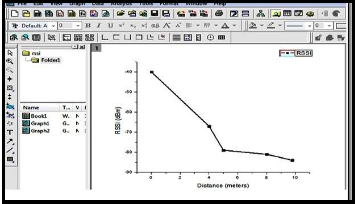

The signal strength indication of XBee series 2 was tested us- ing USB to UART convertor connected to it and tested on con-

dition such that they are between the indoor of the room. Ta-

IJSER © 2015

International Journal of Scientific & Engineering Research, Volume 6, Issue 4, April-2015 561

ISSN 2229-5518

ble 2 shows the actual value obtained from the X-CTU soft- ware on testing the signal strength indicator for XBee module. TABLE 2. READING OF RSSI AND INDOOR DISTANCE FOR

XBEE MODULE

The fig.8 shows a plot of RSSI values in dBm versus distance in meters. The longest detect range for XBee is up to 9.77m, and captured RSSI value is -84 dBm. As the distance is in- creased, signal strength of XBee is decreased.Fig.9 indicates RSSI indication of XBee module in X-CTU.

Fig. 8. A plot of RSSI (dBm) vs Distance (meters)

Fig. 9. RSSI indicator of XBee module in X-CTU

In order to perform the correct operation of the proposed sys- tem, we selected a fixed phone number in our system and ap- plied different operations (monitoring). The user is from the different locations than the gas leakage place “[8]”. Fig.10 shows the pictures taken from user mobile phone after the fixed phone number in GSM shield sends SMS when gas leak-

age happens.

The mobile phones do not require to have any special applica- tions or hardware to be used in this system, and any mobile phone supporting the SMS service could be used in the sys- tem. At normal situation, just one mobile phone number de- pended to send/receive command-messages in the system (i.e. homeowner’s phone number). But, to add additional numbers, it can be done very easily by changing the related source code.

Fig.10.SMS indication on user mobile phone

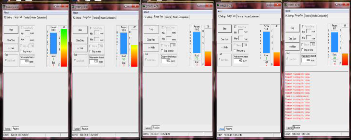

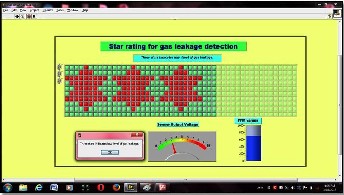

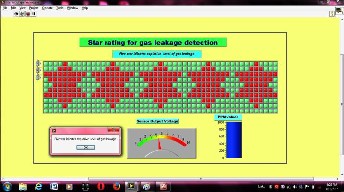

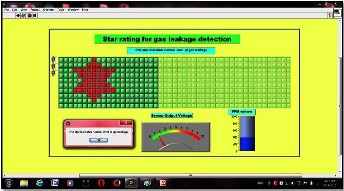

The LabVIEW graphical user interface (GUI) was used to mon- itor the leakage level of gas concentration. It offers unrivaled integration with thousands of hardware devices and provides hundreds of built-in libraries for 14 advanced analysis and data visualization – all for creating virtual instrumentation [6]. The LPG detection using LabVIEW is demonstrated using star rating. Figure 11, 12 and 13 indicate three levels of gas leakage, i.e normal, low and explosive level. If the gas concentration is less than 400 ppm and sensor output voltage is less than or equal to 1.5V, then LabVIEW front panel will display one star which indicates normal level of gas leakage.

If the gas concentration is in the 400 to 800 ppm range and sensor output voltage is between 1.5V to 4.2V, then LabVIEW front panel will display three stars which indicate low level of gas leakage. If the gas concentration is greater than 800 ppm and sensor output voltage is also greater than 4.2V, then Lab- VIEW front panel will display five stars, which indicates ex- plosive level of gas leakage. Based on the GUI, there are volt- meter and gas tank provided, to ease user’s to observe the lev- el of gas leak. Fig. 11, Fig.12, Fig.13 shows the gas leakage monitoring system in normal level, low level and explosive level respectively.

IJSER © 2015

International Journal of Scientific & Engineering Research, Volume 6, Issue 4, April-2015 562

ISSN 2229-5518

Fig. 11.Gas leakage monitoring system in normal level condition

Fig. 12.Gas leakage monitoring system in low level condition

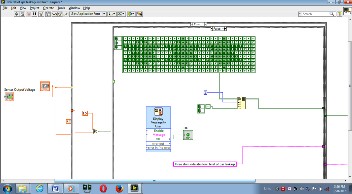

Fig. 13.Gas leakage monitoring system in explosive level condition The programming of these is done by using block diagram in LabVIEW software.Fig. shows programming of GUI using

LabVIEW software.

Fig. 14. shows programming of GUI using LabVIEW software.

The proposed system describes a new visual LabVIEW ap- proach in the area of gas leakage detection at a low gas con- centration. The leakage is detected with the help of MQ-2 gas sensor. As a conclusion, reading of the output voltage from the gas sensor shows the value of concentration and level of explosiveness in LabVIEW using five star rating. The designed system monitors the gas leakage detection via Arduino micro- controller depending on the GSM network. The most im- portant is that the mobile phone does not requires any special application or hardware to be used in this system, and any mobile phone supporting the SMS service could be used in the system. The system also gives an advantage to the user to easi- ly get the information about the gas leakage area by monitor- ing the system using PC/Laptop via Zigbee wireless.

[1] J.Ding, J.Wang, N.Yuan, and Q.Pan, “The Monitoring System of Leak- age Accidents in Crude Oil Pipeline based on Zigbee Technology”, IEEE Changzhou University, 2011.

[2] T.H.Mujawar,V.D.Bachuwar,S.S.Suryavanshi,” Air Pollution Monitor- ing System in Solapur City using Wireless Sensor Network”, Proceedings published by International Journal of Computer Applications® (IJCA), CCSN-2013 (1):11-15, December 2013.

[3] J. Bangali, A. Shaligram, “Energy efficient Smart home based on Wire- less Sensor Network using LabVIEW”, American Journal of Engineering Research (AJER), Vol.2, Issue.12, pp. 409-413, 2013

[4] HANWEI SENSORS, MQ-2 Datasheets www.hwsensor.com.

[5] D. Wheat., “Arduino Internals”, BOOK, Paul Manning, New York,

2011.

[ 6] M. Banzi, “Getting Started with Arduino”, BOOK, O’Reilly Media,

USA, 2nd Edition, 2011.

[7]Selvapriya C, Sathya Prabha, Abdulrahim , Aarthi K C, “LPG Leakage Monitoring and Multilevel Alerting System”, international journal of en- gineering sciences & research Technology (IJSERT), [Selvapriya, 2(11): November, 2013]

[8] A.Shrivastava, R.Prabhaker, R.Kumar and R.Verma, “GSM Based Gas Leakage Detecton System”,International Journal of Emerging Trends in Electrical and Electronics (IJETEE-ISSN: 2320-9569), Vol.3, Issue. 2, May,

2013.

[9] Wireless Sensor Network Research Group, http://www.sensornetworks.org

* Department of Electronics (Commun.Sci.), School of Physi- cal Sciences, Solapur University, Solapur 413 255, M.S, India.

** Department of Electronic Science, University of Pune, Pune-

411 007, M.S., India.

1

m.tabbsum@gmail.com,4 laldeshmukh@gmail.com

IJSER © 2015

International Journal of Scientific & Engineering Research, Volume 6, Issue 4, April-2015 563

ISSN 2229-5518

IJSER © 2015