International Journal of Scientific & Engineering Research, Volume 3, Issue 6, June-2012 1

ISSN 2229-5518

An Optimized Decision for Opportunistic Main- tenance or Event-Driven Maintenance of

Industrial System

Aashish khaira, Amit Kumar Jain

Abstract- Opportunistic maintenance or event driven maintenance gives the maintenance staff an opportunity to replace or repair those items, which are found to be defective or need replacement in the immediate future, during the maintenance of a machine or co mponent. This research paper presents an intelligent decision making method of how to decide whether a particular com ponent requires opportunistic maintenance or not, and if so how cost effective this opportunity-based maintenance will be when compared to a probable future grounding. In this paper we are discussing opportunistic maintenance as an alternate strategy for m aintenance along with steps for implementing it then finally looking at the challenges posed for doing opportunity maintenance.

Index Terms— Maintenance, Opportunistic Maintenance, Industrial system, Cost, Optimised Maintenance, Decision making.

—————————— ——————————

1. INTRODUCTION

aintenance has been defined as the combination of technical and associated administrative actions in tended to retain an item or system in, or restore it to, a state in which it can perform its required

function (ISO 14224: 2004) [1]. A proper maintenance needs technical skills, techniques, methods to properly utilize the assets like factories, power plants, vehicles, equipments and machines. The key objective of maintenance is to ensure system function (availability, efficiency and product quali- ty), system life (asset management), and system safety with low energy consumption. Poorly maintained machines or equipments may lead to random breakdowns causing unavai- lability for production or service. This generally results into lower utilization and hence the lower productivity. Therefore, maintenance is directly linked to the competitiveness and profitability of an organization.

Maintenance Engineers are always on the lookout for ways of reducing system down time and increasing availability, with- out compromising on required level of system reliability. The ultimate objective of any maintenance regime is to maintain the system functionality to the maximum extent possible with optimum tradeoffs between the down times and cost of main- tenance, avoiding any hazardous failures.

————————————————

Aashish Khaira, Pursuing M-Tech (Maintenance Engineering & Ma n- agement), Department of Mechanical Engineering M.A.N.I.T. Bhopal India. ashish_2285@yahoo.co.in

Amit Kumar Jain, Pursuing M-Tech (Maintenance Engineering & Management), Department of Mechanical Engineering M.A.N.I.T.

Bhopal India. amitkumarjain05@gmail.com

Two questions naturally emerge: when to perform a predic- tive maintenance action; how a maintenance expert can take advantage of a given predictive maintenance action that will have to be performed. These questions concern maintenance decision making and lead to the notion of opportune mainten- ance actions.Today most conventional maintenance strategies are purely reactive, corrective (fixing or replacing equipment after it fails) or time -scheduled. These strategies are not well adapted to the control of the global performances of a manu- facturing system [2]. Therefore it isnow necessary to move from traditional maintenance strategies towards condition - based maintenance performed only when a certain level of equipment deterioration occurs, or predictive maintenance which anticipates the appearance of a failure. This notion of anticipation becomes of true importance whenever a progno- sis process is available. Indeed the notion of anticipation al- lows the investigation of non-planned maintenance actions, which is part of what is called opportunistic maintenance. Opportunistic maintenance aims at answering the following questions: When to perform a particular maintenance action? What components should benefit from a preventive mainten- ance action? Which components should first benefit from a preventive maintenance intervention? Opportunistic main- tenance can be defined as a systematic method of collecting, investigating, preplanning, and publishing a set of proposed maintenance tasks and acting on them when there is an un- scheduled failure or repair "opportunity" [3].

Opportunistic maintenance works out to be the perfect reme- dy, which utilizes the opportunity of system shutdown or module dismantle to perform any maintenance required in the immediate future and saves a substantial amount of sys- tem down-time.

IJSER © 2012

http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 3, Issue 6, June-2012 2

ISSN 2229-5518

2. OBJECTIVES

Modern engineering systems, like process and energy systems, transport systems, offshore structures, bridges, pipelines are designed to ensure successful operation throughout the antic- ipated service life, in compliance with given safety require- ments related to the risk posed to the personnel, the public and the environment. Unfortunately, the threat of deteriorat- ing processes is always present, so that it is necessary to install proper maintenance measures to control the development of deterioration and ensure the performance of the system throughout its service life. This requires decisions on what to inspect and maintain, how to inspect and maintain, and when to inspect and maintain. These decisions are to be taken so as to achieve the maximum benefit from the control of the de- gradation process while minimizing the impact on the opera- tion of the system and other economical and safety conse- quences. In this paper an attempt is made to help in decision making for switch on opportunistic maintenance which will help to lower the maintenance cost by considering the failure of one component as an opportunity to replace yet non-failed components in order to prevent future failures.

3. OPPORTUNISTIC MAINTENANCE STRATEGY

Opportunistic maintenance allows the lowest cost and most effective maintenance programme by determining the correct activity at the correct time. In comparison, preventive main- tenance assumes that operating time is the key factor in de- termining the probable condition of equipment. If there is not a close relationship between operating time and the need for maintenance, these preventive maintenance activities are often not needed and maintenance resources are wasted. Sometimes the equipment is in worse condition after maintenance is per- formed and will fail sooner than if nothing were done.

This maintenance strategy is considered important when deal- ing with complex systems that contain expensive items with hard lives with condition-based maintenance (CBM) strate- gies. In this strategy, preventive maintenance activities are combined with corrective ones as soon as a certain technical and economical conditions are satisfied. Opportunity-based maintenance strategy involves several nonlinear variables which affect the total cost of maintenance that should be opti- mized to result in a cost-effective decision on maintenance actions. At the time of failure of one component, a decision is to be made on which additional components to replace in or- der to minimize the expected maintenance cost over planning period. Opportunistic maintenance can be thought of as a modification of the run-to-fail maintenance management phi- losophy.

Opportunistic maintenance allows the lowest cost and most effective maintenance programme by determining the correct activity at the correct time. In comparison, preventive main- tenance assumes that operating time is the key factor in de- termining the probable condition of equipment. If there is not

a close relationship between operating time and the need for maintenance, these preventive maintenance activities are often not needed and maintenance resources are wasted. Sometimes the equipment is in worse condition after maintenance is per- formed and will fail sooner than if nothing were done.

Generally, there are two main purposes for applying opportu- nistic maintenance:

1. To extend equipment lifetime or at least the mean time to the next failure whose repair may be costly? It is expected that this maintenance policy can reduce the frequency of service interruption and the many undesirable consequences of such interruption, and

2. To take advantage of the resources, efforts and time already dedicated to the maintenance of other parts in the system in order to cut cost.

Opportunistic maintenance consists of opportunistic replace- ment policies and opportunistic build policies. Replacement policies specify which parts to remove when an opportunity arises. Build policies specify which parts should be taken from the spares inventory to replace the parts removed according to the opportunistic replacement policies. Both policies should be used to reduce future maintenance requirements [4].

4. CATEGORIES OF OPPORTUNISTIC MAIN- TENANCE

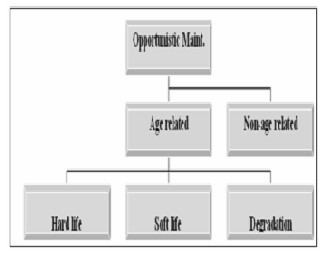

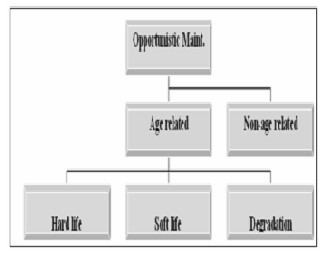

The opportunistic maintenance may be divided into two cate- gories: 1. Age related, and 2. Non-age related. Fig. 1 shows the main categories of opportunistic maintenance.

• Non–age related opportunistic maintenance: the mainten- ance of those items, which failed before, but went undetected until the module’s strip. These are the items, which are inac- cessible unless the modules containing them are completely dismantled and whose failures do not cause system failure.

• Age–related opportunistic maintenance [5]: This category contains three sub-categories as follows:

1) Hard life: is defined as the age of the component, at or by which the component has to be replaced.

2) Soft life: is the age of the component after which it will be rejected the next time one of the modules contain- ing it is recovered.

3) Degradation: failure mechanisms are monitored through condition monitoring devices and compo- nents are repaired or replaced once the condition dete- riorates to a critical level.

IJSER © 2012

http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 3, Issue 6, June-2012 3

ISSN 2229-5518

Fig. 1 Categories of Opportunistic Maintenance

Strategy

5. STEPS FOR EFFICIENT OPPORTUNISTIC MAINTENANCE.

In opportunity-based maintenance of a certain component, three important variables need to be collected and analyzed as follows:

1) The remaining life of component or sub-module under consideration.

2) The cost of down time that will occur if one decides to wait until the component has exhausted its useful life.

3) The cost of risk involved or the probability of failure.

For an opportunity maintenance to occur there must have been failure / unscheduled stoppage of a machine which has resulted in partial or full stoppage of a process area. How fast and accurate your planner can pull the list of maintenance work lists for the opportunity? This is very crucial step in maximizing the utilization of this.

Following are the list of activities envisaged for such an op- portunity [6]:

1) Identify the duration of the breakdown; alternatively plan for the opportunity time.

2) Pull list of maintenance work(s) meeting the oppor- tunity time.

3) Prioritize the work lists.

4) Determine the no of hours required; find out the

available capacity.

5) Material availability check; plan for material issue from stores.

6) Decide if required to go for external service in case the demand capacity is more.

7) This may involve pre scheduling some work orders

planned in within near future time (1-2 weeks)

8) Execute and complete the work / report the work or- ders completed.

6. SCHEDULING PRINCIPLE FOR OPPORTU- NISTIC MAINTENANCE

The core objective of the opportunity maintenance is to com- plete as much maintenance work as possible within the oppor- tunity, however the principal theory behind opportunity maintenance would be to execute only such works which are falling in the opportunity maintenance which would other- wise require scheduled stoppage of the specific area. One would need to be experienced enough to decide on how much of future maintenance work can be bring forward in time?

Considering example of breakdown of a machine which is expected to take 5 days to restore it back like in boiler part failure. This has resulted in the stoppage of the production area. The primary focus would be on to restore the machine as quickly as possible and restore the machine back to its original condition. However there is work orders which are falling within those 5 days + 2weeks window of time which needs to be executed and subsequently these will also stop the process. Other work orders which does not necessitate production stoppages and falling in this can also be clubbed maximize the utilization of opportunity maintenance.

7. OPTIMIZED DECISION MAKING MODULE FOR OPPORTUNISTIC MAINTENANCE.

Decision making can be regarded as the mental processes (cognitive process) resulting in the selection of a course of ac- tion among several alternative scenarios. Every decision mak- ing process produces a final choice. The output can be an ac- tion or an opinion of choice [7].

Decision making techniques:

Some of the decision making techniques used generally in-

cludes:

1) Pros and Cons: Listing the advantages and disadvan- tages of each option, Contrast the costs and benefits of all alternatives. Also called rational decision making.

2) Simple Prioritization: Choosing the alternative with

the highest probability-weighted utility for each al- ternative.

3) Satisficing : Examine alternatives only until an ac- ceptable one is found.

4) Acquiesce to a person in authority or an "expert", just following orders

5) Opportunity cost: calculating the opportunity cost of each options and decide the decision.

For efficient Decision making for opportunistic maintenance one must follow these:

1) Objectives must first be established like reduction in

downtime, increasing availability of machines etc.

2) Objectives must be classified and placed in order of importance.

3) Alternative actions for utilization of this strategy must be developed.

IJSER © 2012

http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 3, Issue 6, June-2012 4

ISSN 2229-5518

4) The alternative must be evaluated against all the ob- jectives.

5) The alternative that is able to achieve all the objectives is the tentative decision.

6) The tentative decision is evaluated for more possible consequences.

7) The decisive actions are taken, and additional actions are taken to prevent any adverse consequences from becoming problems.

8) There are steps that are generally followed that result in a decision model that can be used to determine an

optimal opportunistic maintenance plan [8].

9) In a situation featuring conflict, role-playing is helpful for predicting decisions to be made by involved main- tenance personnel [9].

8. FRAME WORK FOR AN OPTIMIZED DECI- SION FOR OPPORTUNISTIC MAINTENANCE OR EVENT-DRIVEN MAINTENANCE OF INDUSTRI- AL SYSTEM

Decision Point 3: The Right Process. Choose the right process for solving problem. It would depend on the decision situa- tion. Making a high quality decision doesn’t have to be time consuming. The only rule is that the mechanics of how you’ll work the decision to conclusion need to be appropriate to the size, significance, and complexity of the decision. How long is too long? When the cost of working the decision any further outweighs the benefits of making a choice.

Work

Decision Point 4: A complete set of alternatives. The more options you generate, the greater your chance of finding an excellent one. You should only stop generating more options when the cost and delay of further search are likely to exceed the benefit.

What is the right number of alternatives? That depends on how you’ve framed the problem. Two terms are helpful in this regard. ―Collectively exhaustive‖ means that the alternatives you’re considering fill the frame: a rational observer would conclude that you’ve thought of everything that matters. ―Mu- tually exclusive‖ means that the alternatives are unique and

different from each other: they’re not just restatements of the

same choice.

Decision Point 5: Values against which to make tradeoffs. Values define your preferences among alternatives. They are your criteria. Values can be expressed by

―attributes.‖Attributes are characteristics of the outcomes that we find desirable or undesirable. They typically occur over time and may have some degree of uncertainty associated with them. For each decision, particularly those involving oth- ers, one should need to make ones definition of value visible, clear, and distinct.

Declare

Fig. 2

Decision Point 6: Information that describes the value of each alternative. Good decision-making requires not only knowing the facts, but understanding the limits of knowledge. The most valuable insights are often found in exploring uncertainties and ―disconfirming‖ information. The effective decision does not, as so many texts on decision-making proclaim, flow from a consensus on the facts. The understanding that underlies the right decisions grows out of the clash and conflict of divergent opinions and out of the serious consideration of competing alternatives.

Decision Point 1: Frame the problem. What are you deciding and why? What shouldn’t you be deciding and why? What’s not in the box is as important as what is. Without a good defi- nition of the problem or opportunity to be worked, there is no possibility that you'll reliably reach a high quality decision. Frames are mental structures we create to simplify and organ- ize industrial system. They help us reduce complexity.

Decision Point 2: The Right Personnel. Choose a person who is having deep & thorough knowledge in the specific field. So that quick & accurate solution of the problem can be found.

9. CHALLENGES FOR OPPORTUNITY MAINTEANCE

Following are challenges envisaged for opportunity mainten- ance [10]:

1) No clear idea on how long the machines under breakdown will be restored - Many times it takes con- siderable time to identify the root cause of the issue hence no accurate duration of machine down time can be predicated. This will impact others getting the benefit of Opportunity window.

IJSER © 2012

http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 3, Issue 6, June-2012 5

ISSN 2229-5518

2) Unavailability of Resource - since the focus will be on breakdown rather than planned maintenance in such situations.

3) Non availability of spares.

4) Non Availability of external service / delay in getting

internal approvals for external service.

5) Sometimes the machine which was under breakdown might be restored earlier than anticipated creating pressure situation on planned maintenance works.

CONCLUSION

"Opportunistic maintenance" is a method of organizing and managing the response to maintenance problems to optimize overall productivity. The key idea behind opportunistic main- tenance is simply to make all preparations for disruptive maintenance in advance and as thoroughly as possible, but to initiate the actual work only when an opportunity arises. In this environment, opportunistic maintenance has proven to be an effective maintenance tool, but it requires enormous coor- dination and accurate planning and more important it requires Management support to make use of opportunity windows. Maintenance Engineers should focus on creating the dynamics that support organizational decision quality on putting in place a decision framework and process that supports organi- zational decision quality rather than raking through the de- tailed minutia of specific decisions. A high quality decision process highlights the frame, potential alternatives, and key assumptions the drive value. This allows Maintenance Engi- neers to spend their time declaring the right decisions, provid- ing a set of common criteria, and testing the key assumptions of each decision.

Predictive maintenance raises new challenges and allows a maintenance expert to investigate and make use of opportuni- ties that could not be exploited before. The notion of oppor- tune maintenance actions was introduced, rigorously defined and discussed, in order to reflect that it now becomes possible, to maintenance purpose, to consider opportunities that are generally ignored. The efforts clearly show that the systematic approach towards the maintenance of equipments and facilities is gaining more and more importance in Achiev- ing the competitive advantage. From the review we can state that multi-criteria approach in selecting or decision making helps decision maker in better decision making and get- ting better insight into the problem situation.

aged us to maintain the level of enthusiasm for completing this paper. We would also like to express our gratitude to all staff members of Mechanical Engineering Department, MA- NIT, Bhopal, for their cooperation in our work. We are also indebted to those who have helped us directly or indirectly to accomplishment of this task.

REFERENCES

[1] Ninth AIMS International Conference on Management , Balasaheb S

Gandhare, Milind Akarte, “Maintenance Strategy Selection”.

[2] 13th IFAC Symposium on Information Control Problems in Manufacturing, INCOM'2009,Moscou : Russian Federation (2009)"Édouard Thomas, Éric Levrat, Benoit Iung, Pierre Co- cheteux, “Opportune maintenance and predictive maintenance decision support “

[3] Savic, G. Walters, J. Knezevic, "Optimal, opportunistic mainten- ance policy using genetic algorithms analysis". Journal of Quali- ty in Maintenance Engineering, Vol. 1, No. 3, 1995, 25-34.

[4] O. Mohamed-Salah, A-K. Daoud, G. Ali, "A simulation model for opportunistic maintenance strategies". 7th IEEE Internatio n- al Conference on Energy Technologies and Factory Automation, Vol. 1, 1999, Barcelona, Spain, 703 – 708.

[5] J. Crocker, U. Kumar, "Age related maintenance versus reliabili-

ty centered maintenance: a case study on aero-engines". Journal of Reliability Engineering and Systems Safety, Vol. 67, No. 2,

2000, 113-118.

[6] Opportunity Maintenance- A point of view

By GopalKrishna,http://www.infosysblogs.com/ sap/2011/

09/opportunity_maintenance-_a_poi.html

[7] James Reason (1990). Human Error. Ashgate. ISBN 1840141042.

[8] Monahan, G. (2000). Management Decision Making. Cambridge: Cambridge University Press. pp. 33–40. ISBN 0521781183.

[9] J. Scott Armstrong (2001). "Role Playing: A Method to Forecast

Decisions"

[10] Opportunity Maintenance- A point of view

By GopalKrishna,http://www.infosysblogs.com/ sap/2011/

09/opportunity_maintenance-_a_poi.html

By the use of Optimized Decision for Opportunistic Mainten- ance in an Industrial System the Cost of Maintenance can be reduced at a huge rate and down time of industrial system can be reduced at a greater extent.

ACKNOWLEDGMENT

We take pleasure in expressing our gratitude towards MAU- LANA AZAD NATIONAL INSTITUTE OF TECHNOLOGY, BHOPAL, and the institute responsible for our intellectual and academic growth. We also gratefully acknowledge the inspir- ing efforts of our Family & Friends, who constantly encour-

IJSER © 2012

http://www.ijser.org