International Journal of Scientific & Engineering Research, Volume 5, Issue 2, February-2014 304

ISSN 2229-5518

Adsorption of Heavy Metal Ions from

Electroplating Wastewater Using Watermelon Peel Activated Carbon: Kinetics and Isotherm Studies

Gin, W.A., Jimoh, A.*, Abdulkareem, A.S., Giwa, A.

Department of Chemical Engineering, School of Engineering and Engineering Technology, Federal University of Technology, Minna, P.M.B. 65, Minna, Niger State, Nigeria

*Corresponding author; E-mail: fatai2011@futminna.edu.ng

Abstract— This work has been carried out to study the kinetics and the isotherms of adsorptions of some heavy metals (zinc, copper, and iron) ions from electroplating wastewater using watermelon peel activated carbon (WPAC) which is a cost-effective adsorbent. In order to achieve these, factors, such as agitation time, adsorbent dosage, pH, and agitation speed, which have effects on the removal of these heavy metals were investigated. The pseudo-first-order and pseudo-second-order kinetic models were used to fit the kinetic data of the adsorption process. Also, the experimental equilibrium data were applied to Langmuir, Freundlich, Dubinin-Radushkevich and Temkin isotherm models and their equilibrium parameters were as well estimated. From the results obtained, using regression coefficient as a yardstick, it was discovered that the pseudo-first-order model was able to fit the generated adsorption data from the heavy metals considered in this work better than the pseudo-second-order model. In addition, most of the isotherm models considered were found to describe the equilibrium data of the process very well because the square of correlation coefficients of most of them were very high.

Index Terms— Heavy metals, watermelon peel activated carbon, adsorption, kinetic, isotherm.

—————————— ——————————

1 INTRODUCTION

he discharge of heavy metals into the environment has become a matter of concern over the last few decades. Numerous industries (e.g., electroplating, metal finishing operations, electronic-circuit production, steel and nonferrous processes, and fine-chemical and pharmaceutical production) discharge a variety of toxic heavy metals into the environ-

ments (Harry, 1999).

Several workers have published many reports on the poten- tial use of agricultural by–products as good substrates for the removal of metal ions from aqueous solutions and wastewaters. This process attempts to put into use the princi-

ple of using waste to treat waste and become even more effi- cient because these agricultural by–products are readily avail- able and often pose waste disposal problems. Hence, they are available at little or no cost since they are waste products. Al- so, this makes the process of treating wastewaters with agri- cultural by–product adsorbents more economical than using conventional adsorbents like activated carbon. In addition, there is no need for complicated regeneration process when using agricultural by–products for wastewater treatment (Abia and Igwe, 2005).

A literature search reveals that no work has reported the kinetic and isotherm study of the use of activated watermelon peel carbon as adsorbent for heavy metal removal from indus- trial wastewater. So, an attempt was made to study the feasi- bility of activated watermelon peel carbon developed from one of our previous studies, for the adsorption of copper, lead, zinc and iron from electroplating wastewater. The effects of pH, agitation speed, contact time, concentration of metal ion,

and concentration of sorbent on the adsorption kinetics were studied. The batch sorption kinetics was studied for the pseu- do-first-order and pseudo second order reactions. In addition, the abilities of four (the Langmuir, Freundlich, Temkin and Dubinin-Radushkevich) isotherm models in modeling the equilibrium data generated from the process were established.

2 MATERIAL AND METHODS

2.1 Effluent Collection

The raw effluent from an electroplating facility from a scientific development institute in Niger State, Nigeria was collected in a sterile 4 L plastic container from its point of discharge to the environment. For preservation, 5 mL of 2.0

M nitric acid was added per litre of the sample. The sample was refrigerated at approximately 4 °C to avoid heavy met- al precipitation and to allow the samples to be kept for fur- ther use.

2.2 Heavy Metal Analysis

The effluent was analyzed for the presence of heavy metals (zinc, iron, copper and lead) by digesting 100ml of the effluent using 10 mL triple acid mixture (5:1:1 - HNO3 :HClO4 :H2 SO4 ) in a 250 mL conical flask placed in a fume cupboard. The samples were properly covered with aluminium foil to avoid spillage and heated on a hot plate until the solution was reduced to 10 mL. Thereafter, it was

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 2, February-2014 305

ISSN 2229-5518

allowed to cool and make up to a mark by topping with distilled water before it was filtered into a 50 mL standard flask, labelled and made ready for further analysis. The concentrations of the heavy metals in the wastewater were determined using Atomic Absorption Spectrometer (Per- kin, 210 vgp).

2.3 Activated Carbon Material

Watermelon peels were obtained from different fruit selling sources in Minna, Nigeria and sun-dried for 2-5 days before being crushed with a mortar and pestle to re- duce their sizes. 15 g of the resulting powdered sample was weighed into six different clean and pre-weighed crucibles, which were then introduced into the hot zone of a muffle furnace (OH85TR Gallenkamp). The peels were carbonized at 300 oC and held at this temperature for 60 min, based on a preliminary investigation carried out on the carboniza- tion of the peels. The content was then removed from the muffle furnace after the set period and cooled in an open air for one hour. This process was repeated until a substan- tial amount of carbonized sample was obtained. Activation of the carbonaceous material produced using 1.0 M zinc chloride was carried out in accordance with the description

ing 20 mL each of the electroplating wastewater to various amounts of the adsorbent (1.0 - 2.0 g) in different plastic bottles covered and agitated on a mechanical shaker. The equilibrium time and the pH were kept constant during this test.

To determine the effect of pH on the adsorption of

metals, the pH of the wastewater was adjusted and main-

tained to the required value (2.0, 3.0, 4.0, 5.0, 6.0 and 7.0)

with a 1.0 M H2 SO4 solution and mixed with the optimum weight of the adsorbent and agitated at a preset equilibri- um time.

In studying the effect of agitation speed, the opti- mal adsorbent dosage of the adsorbent was used to adsorb the heavy metals at different agitation speeds by adding the optimal dosage of the adsorbent to 20 mL of each of the electroplating wastewater in different plastic bottles and agitated for 1 h. The agitation speed was adjusted from 150 rpm to 300 rpm. The content of each bottle was filtered and analyzed.

The adsorption capacity (qe ) was determined using the mass balance expression (Equation 1) obtained from the work of Horsfall et al. (2006).

reported by Yalc et al. (2000). The activated material pro-

duced was subjected to characterization in order to test for properties like fixed carbon, bulk density, ash, volatile and

q = V (C o − C e )

e M

(1)

moisture content. The fixed carbon content was determined using the procedure described in ASTM (2001) while the

volatile matter, ash content, and fixed carbon were con- ducted using the procedure laid down by the Association

Also, the adsorption capacity (q t ) at time t was de- termined using the Equation (2) that was found in the work of Demirbas et al. (2004).

of Analytical Chemistry, AOAC (1994).

V (C

− C )

2.4 Adsorption and Kinetics Studies

qt = o t

M

(2)

Effects of some selected reaction parameters on the rates of adsorption of metal ions from the waste sample using the developed activated watermelon peel were inves- tigated. The parameters considered include agitation time, adsorbent dosage, pH and agitation speed. To study the effect of agitation time on metal adsorption by watermelon peel activated carbon, 20 mL of the electroplating wastewater was transferred into sterile plastic bottles, cov- ered and labelled accordingly. 1.0 g of the adsorbent was weighed into a labelled bottle and agitated for different contact durations (15, 30, 45, 60 and 75 min). After each agi- tated time, the content of the bottle was filtered. The equi- librium concentration of each of the metals in the filtrate was determined. This modified procedure is in accordance with the reported work of Elaigwu et al. (2009).

The effect of adsorbent dosage, that is, the amount of carbon on the adsorption of metals was studied by add-

Where Co is the initial metal ions concentration, Ce is the concentration of metal ions in solution (mol/L) at equilibri- um, Ct is the concentration of metal ions in solution (mol/L) at time t in solution, V is volume of initial metal ions solution used (L) and M is mass of adsorbent used (g).

Furthermore, kinetics of adsorption was studied by

analyzing the adsorptive uptake of heavy metals from

wastewater at different time intervals. The pseudo-first- order and pseudo-second-order model equations were fit- ted to model the kinetics of heavy metal adsorption onto the produced activated carbon. The linearity of each model, when plotted, was used to find out how suitable each mod- el was for the adsorption.

As such, in this work, using the data generated

from the experiments carried out, and considering the line-

arized forms of pseudo-first-order and pseudo-second-

order reaction models given in Equations (3) and (4), re-

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 2, February-2014 306

ISSN 2229-5518

spectively, the model parameters were estimated.

3.1 Heavy Metal Analysis

Industrial discharge is recognized as one of the ma-

log(q e

− qt

) = log q e

− k1 t

2.303

(3)

jor sources of toxic chemicals in the environment. In the present study, the metal ions contained in an electroplating effluent have been removed using watermelon peel activat-

t = 1 + t

2

(4)

ed carbon. Heavy metal analysis of the effluent sample

showed the presence of Cu, Fe, Pb and Zn at various con-

qt k 2 q e q e

centrations even beyond the permissible limits set by regu- latory authorities (see Table 1).

q = q m K L C e

(5)

e 1 + K

L C e

Table 1. Chemical properties of the electroplating effluent

1

q e = k f C n

(6)

q e =

RT

ln KT +

b

RT

ln C e

b

(7)

ln q e = ln q D − BD ε 2

(8)

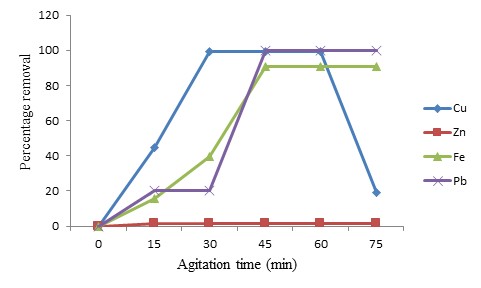

3.2 Effect of Agitation Time on Adsorption of Heavy

Metals

Later, with the aid of the generated data from the adsorption studies of this work, the parameters contained in Langmuir, Freundlich, Temkin and Dubinin- Radushkevich adsorption isotherms were estimated using Equations (5), (6), (7) and (8), respectively.

3 RESULTS AND DISCUSSIONS

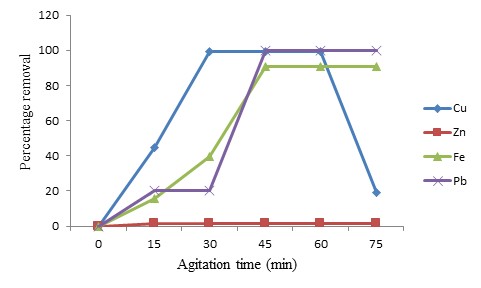

Shown in Figure 1 are the results obtained from the experiment that was performed by adding 1g of WPAC to

20 mL of electroplating waste water at constant tempera- ture. In the experiment, the agitation speed was maintained at 100 rpm when the pH of the wastewater was 2.

Figure 1: Rate of removal of heavy metals with agitation time using watermelon peel (WPAC)

The result presented in Figure 1 indicated that the

rate of adsorption increased significantly for some of the

metal ions present in the electroplating wastewater be-

tween 15 – 60 min of contact time. This results were found

to be important because equilibrium time is one of the im-

portant parameters for an economical wastewater treat-

ment system. This trend was also found to be consistent with the observation made by Innocent et al. (2009). The

rapid initial rate increased followed by a slow rate at a later period was attributed to the availability of excess adsorp-

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 2, February-2014 307

ISSN 2229-5518

tion sites on the adsorbents. The initial high adsorption rate was found to be due to ion exchange followed by a slow chemical reaction of the metal ions with active functional groups on the sample.

It was also observed from Figure 1 that most of the

metal ions were optimally adsorbed within 45 min of con-

tact between the WPAC and heavy metals, and it was even

discovered that there were 99.1%, 1.4%, 90.6% and 100%

removal for Cu, Zn, Fe and Pb respectively within that time. The order of the adsorption using the developed acti-

vated carbon was found to be zinc < copper < iron < lead.

3.3 The Effect of Adsorbent Dosage

The effect of adsorbent dosage on the uptake of the four heavy metals onto the adsorbent was studied at the optimized agitation time and the results obtained are as presented in Figure 2 shown below.

Figure 2: Rate of removal of heavy metals with WPAC adsorbent dosage

As can be seen from Figure 2, it was revealed that heavy metal removal increases with increase in adsorbent dosage. For the adsorbent, the removal was found to re- main unchanged after 2.0 g per 20 mL of the dosage for all the metal ions. The further increase in adsorption for Zn and Fe with adsorbent dosage was found to be as a result of the availability of greater area and more adsorption sites. At adsorbent dosage (m) < 1.8 g, the adsorbent surface was found to become saturated with the ions and the residual ion in the electroplating water was discovered to be large. With increase in adsorption dosage, the metal ions in- creased due to increased metal ion uptake by increased amount of adsorbent. At adsorbent dosage greater than 1.8 g, the increased ion removal became very low as surface metal ion and electroplating wastewater ions were in equi- librium with each other. At about 2.0 g, the removal effi- ciency was discovered to become almost constant. Maxi- mum removals of metals were found to be 99.5 % for Cu,

37.4 % for Zn, 94.6 % for Fe and 100 % for Pb.

3.4 Effect of pH on Adsorption of Heavy Metals

The pH of a solution affects the surface charge of the adsorbent as well as the degree of the ionization and speciation of the pollutants. A change in pH normally af- fects the adsorptive process through dissociation of the functional groups on the adsorbent surface active sites. The effect of pH was studied in this work at room temperature by adjusting the pH of the wastewater considered to the required value (2.0, 3.0, 4.0, 5.0, 6.0 and 7.0) with a 1.0 M H2 SO4 solution before it was then mixed with the optimum weight of the adsorbent and agitated at a preset equilibri- um time. The results obtained from the studies carried out on the effects of pH on the quantity of heavy metal removal using WPAC are as presented in Figure 3. From the figure, it was observed that the maximum uptake percentage of heavy metal removals, for all the heavy metals considered, was observed when the pH of the solution was 7. It was also discovered that lead did not show any dependence on the pH of the solution.

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 2, February-2014 308

ISSN 2229-5518

Figure 3: Changes in heavy metal removal with pH using WPAC

3.5 Effect of Agitation Speed on Adsorption of Heavy

Metals

The effect of agitation speed was also studied at room temperature by adding the optimal dosage of the WPAC developed to 20 mL of electroplating wastewater in different plastic bottles, agitating for 1 h and adjusting the

agitation speed from 100 rpm to 300 rpm. The values of the heavy metal percentage removals obtained when the agita- tion speed was varied from 100 to 300 rpm are as given in Figure 4.

Figure 4: Variation of Heavy Metal Removal with Agitation Speed Using WPAC

According to the figure, the increase in the shaking speed from 100 - 300 rpm of the wastewater was found to only slightly increase the percentage removal of metal ions (iron, copper, and lead) considered up to 300 rpm with the exception of zinc in which the percentage removal was somehow significant. Specifically, maximum performances of 99.1% removal of Cu, 1.4% of Zn, 90.6% Fe and 100% of Pb at 45 min agitation time, 1.8 g adsorbent dosage, and pH of 6 were obtained at 200 rpm agitation speed.

3.6 Adsorption Kinetics

Adsorption is a mass transfer process that involves transfer of adsorbate from liquid phase into solid phase, and it is divided into 3 steps: (i) boundary layer mass trans- fer across the liquid film surrounding the particle, (ii) in- ternal diffusion/mass transport within the particle bounda- ry as pore and/or solid diffusion, (iii) adsorption within the particle and/or on the external surface. In this study, the data obtained on the dependence of adsorption capacity with time were used for kinetic analysis. The adsorption

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 2, February-2014 309

ISSN 2229-5518

was carried out using adsorbent dosage = 1.8 g/20 ml, agita- tion time = 60 min, pH = 6, and agitation speed = 250 rpm.

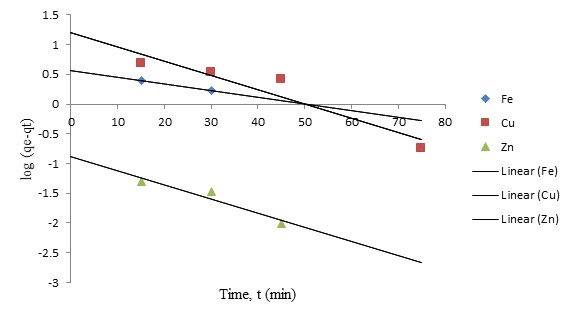

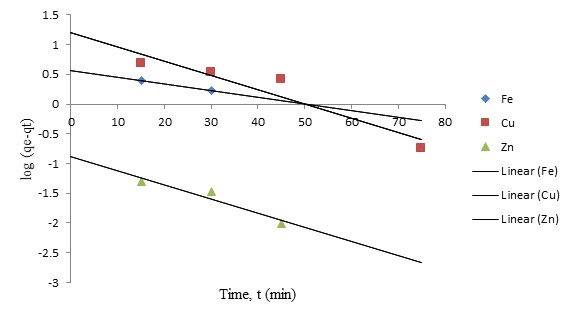

The results of the fitted data on the adsorption of heavy metals using 1.8 g of WPAC per 20 mL of electro-

plating wastewater at 45 min agitation time and pH of 6 are as presented in Figures 5 and 6.

Figure 5: Pseudo-first-order reaction model for adsorption of heavy metals on WPAC

Figure 6: Pseudo-second-order reaction model for adsorption of heavy metals WPAC

It was clear from Figures 5 and 6 that the obtained

data fitted relatively well for all the metals with pseudo-

first-order reaction and pseudo-second-order reaction

models. The estimated coefficients of the empirical kinetic

models are as given in Table 2.

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 2, February-2014 310

ISSN 2229-5518

Table 2. Coefficient of empirical kinetic models for WPAC

Adsorbent | Metal | | Pseudo-first-order reaction model | | Pseudo-second-order reaction model |

| | k1 | R1 2 | qe, (mg/g) | k2 gmg-1in-1 | qe, (mg/g) | R2 2 |

WPAC | Fe2+ | 0.0256 | 0.999 | 3.664 | 0.0002 | 14.492 | 0.100 |

WPAC | Cu2+ | 0.0552 | 0.890 | 16.218 | 0.0050 | 11.494 | 0.907 |

WPAC | Zn2+ | 0.0529 | 0.919 | 0.129 | 10.0000 | 1.000 | 0.999 |

It was discovered from the results shown in Fig-

ures 5 and 6 obtained from the fittings carried out using

Equations (3) and (4) for the pseudo-first-order and the

pseudo-second-order reaction models, respectively, that the two models were able to give good straight lines for the metals (copper, zinc and iron) except for iron in which the pseudo-second order model could not fit into its data well.

The results given in Table 2 have shown that the

linear regression coefficient values R1 2 of the pseudo-first- order reaction model which were estimated to be 0.999,

0.890 and 0.919 for Fe2+, Cu2+ and Zn2+ respectively were found to be better than those of the pseudo-second-order reaction model that were found to be 0.100, 0.907 and 0.999

for Fe2+, Cu2+ and Zn2+, respectively. These facts have re- vealed that the adsorption of heavy metals by activated

carbon from watermelon peel can be better described by

pseudo-first-order reaction model, which assumes that a

non-dissociating molecular adsorption of heavy metals

were occurring on WPAC, and that the adsorption phe- nomenon of this work is diffusion controlled.

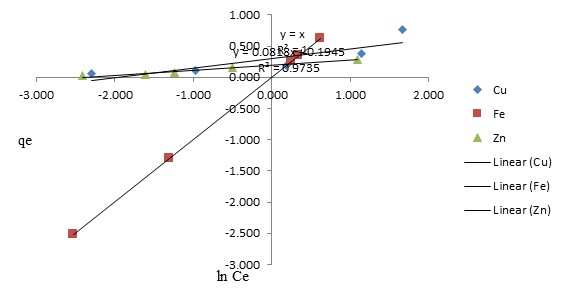

3.7 Adsorption Isotherms

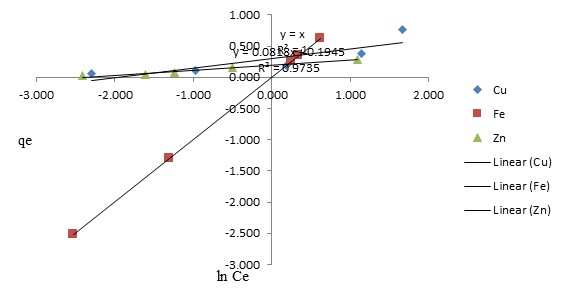

In this work, equilibrium analysis has been carried out on the data dependence of adsorption capacity to initial copper, zinc and iron concentration. The results obtained from the adsorption of copper, zinc and iron using 20 mL electroplating wastewater and 1.8 g activated watermelon activated carbon at 45 min agitation time and pH of 6 are as given in Figures 7-10.

Figure 7: Langmuir adsorption isotherm for adsorption of heavy metals on activated carbon from WPAC

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 2, February-2014 311

ISSN 2229-5518

Figure 8: Temkin adsorption isotherm for adsorption of heavy metals on activated carbon from WPAC

Figure 9: Freundlich adsorption isotherm for adsorption of heavy metals on activated carbon from WPAC

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 2, February-2014 312

ISSN 2229-5518

Figure 10: Dubinin-Radushkevich adsorption isotherm for adsorption of heavy metals on activated carbon from WPAC

Shown in Figures 7, 8, 9 and 10 are the results of

the fitting of Langmuir, Freundlich, Temkin and Dubinin-

Radushkevich respectively to copper, zinc and iron uptake

data onto WPAC. The results showed that the four iso- therm models were able to describe the partitioning be-

tween the solid and the liquid by evaluating the maximum

adsorption efficiency of the adsorbents well. The models

adsorption parameters and the correlation coefficients es-

timated are as given in Table 3.

Table 3. Isotherm model constants and correlation coefficients for heavy metals adsorption onto WPAC

Isotherm Models Constants Unit

Value

Cu2+ Fe2+ Zn2+

Langmuir Freundlich Temkin

Dubinin-Radushkevich

qm mgg-1 1.1135 8.1300 0.4618

KL Lmg-1 0.2480 -61.5 0.5957

R2 - 0.568 0.749 0.891

kf mgg-1 0.2041 0.1156 0.1618 n - 1.548 1.362 1.293

R2 - 0.970 0.735 0.919

KT Lmg-1 1.980519 1 10.96888

B - 16088.13 2477.572 30587.31

R2 - 0.741 1 0.973

E KJmol-1 34.06014 52.41424 31.28056

qD mgg-1 0.541723 0.554327 0.468134

B mol2KJ-2 0.000431 0.000182 0.000511

R2 - 0.871 0.829 0.978

The adsorption isotherm model parameters esti-

mated using the expressions given in Equations (5), (6), (7)

and (8) for Langmuir, Freundlich, Temkin and Dubinin-

Radushkevich adsorption models respectively are given in

Table 3.

The value of the Langmiur constant, q m computed

and found to be 1.1135, 8.1300 and 0.4618 mgg-1 for Cu2+ ,

Fe2+, Zn2+ respectively indicated that the best adsorption

was found to occur at low concentration of the heavy metal compared to Freundlich constant Kf (0.2041, 0.1156 and

0.1618 mgg-1) and Dubinin-Radushkevich constant, qD

(0.541723, 0.554327 and 0.468134 mgg-1). Also, judging the

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 2, February-2014 313

ISSN 2229-5518

applicability of the isotherm model by the square of the correlation coefficients (R2), it was observed that the gener- ated data fitted the models relatively well because their square of correlation coefficients were found to be greater than 0.7 except that of Langmuir isotherm for copper re- moval that was found to be 0.568 .

4 CONCLUSIONS

From the results obtained from this work that ap- plied two kinetic and four isotherm models to investigate the adsorption of copper, zinc, and iron from electroplating wastewater onto cassava peel activated carbon, it has been revealed that, using the square of regression coefficient as the yardstick, the pseudo-first-order model was discovered to fit the generated adsorption data from the heavy metals investigated better than the pseudo-second-order model. In addition, most of the isotherm models studied were found to perform very well in representing the generated adsorp- tion data for the heavy metal removals because the square of correlation coefficients of most of them were found to be greater than 0.7.

NOMENCLATURES

AOAC Association of Analytical Chemistry

ASTM American Society for Testing and Materials

b Langmuir constant (energy of adsorption) (L/mg)

Ce Concentration of metal ions in solution (mol/L) at

equilibrium,

Co Initial metal ion concentration (mol/L)

Ct Concentration of metal ions in solution at time t

(mol/L)

FAO Food and Agriculture Organization

FEPA Federal Environmental Protection Agency

k1 Adsorption rate constant of pseudo-first-order ki- netic model (min-1)

k2 Adsorption rate constant of pseudo-second-order kinetic model (g mg-1 min-1)

Kf Freundlich constant related to adsorption capacity

KL Constant related to the affinity of the binding sites

and energy of adsorption (L/mg)

KT Temkin equilibrium binding constants correspond-

ing to the maximum binding energy (L/mg) M Mass of adsorbent used (g)

n Freundlich constant related to adsorption intensity q Amount of heavy metal ions adsorbed at time t,

mgg-1

qD Adsorption capacity (mg/g)

qe Amount of heavy metals adsorbed at equilibrium

time mgg-1

qm Langmuir constant (adsorption capacity) (mg/g)

R Universal gas constant (Jmol-1K) T Absolute temperature (K)

t Time, min

USEPA United States Environmental Protection Agency V Volume of initial metal ions solution used (L) WPAC Watermelon peel activated carbon

ε Polanyi potential

REFERENCES

[1] Abia, A.A. and Igwe, J.C. 2005. Sorption kinetics and intraparticulate diffusivities of Cd, Pb, and Zn ions on maize cob. Journal of Biotechnology, 4(6), 509-512.

[2] Association of Official Analytical Chemists (AOAC).

1994. Official methods of analysis, 14th Ed. Association

of Official Analytic Chemists, Washington DC.

[3] ASTM (2001). Activated carbon standards. American

Society for Testing and Materials. Online. Fritz Publi- cation. Http: //www.Fritz.Com.

[4] Demirbas, A. 2004. Adsorption of lead and cadmium ions in aqueous solutions onto modified lignin from alkali glycerol delignication. Journal of Hazardous Ma- terials, 109, 221-226.

[5] Elaigwu, S. E., Usman, L. A., Awolola, G.V., Adebayo, and Ajayi R.M. (2009). Adsorption of Pb (II) from aqueous solution by activated carbon pre- pared from cow dung. Advances in Natural and Ap- plied Sciences, 3(3), 442-446

[6] FAO (Food and Agriculture Organization). 2006. Sta- tistical database of Food and Agricultural Organiza- tion of the United Nations. Available at http://faostat.fao.org/ (acessed august 2007; verified August 2, 2008). FAO, Rome.

[7] FEPA (Federal Environmental Protection Agency).

(2001). National Guidelines and Standards for Water

in Nigeria, Lagos, Nigeria. Federal Environmental

Protection Agency.

[8] Eccles, H. 1999. Treatment of metal-contaminated

wastes: why select a biological process? Trends in Bi-

otechnology, 17(12), 462-465.

[9] Horsfall Jnr. M., Spiff, A.I. and Abia, A.A. 2004. Stud- ies on the influence of mercaptoacetic acid (MAA) modification of cassava (Manihot sculenta Cranz) waste biomass on the adsorption of Cu2+ and Cd2+ from aqueous solution. Bulletin of the Korean Chem- ical Society, 25(7), 969-976.

[10] Innocent, O., Emmanuel, A. and Thomas, A. 2009.

Biosorption of heavy metal ions from aqueous solu- tions using a biomaterial. Leonardo Journal of Sciences,

14, 58-65.

IJSER © 2014 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 5, Issue 2, February-2014

ISSN 2229-5518

[11] USEPA (United States Environmental Protection Agency). (1979). Human Health Effects of Molyb denum in Drinking Water. EPA, 65-77.

[12] Yale, N. and Sevinc, V. (2000). Studies of the surface area and porosity of activated carbons prepared from

rice husks. Carbon, 38, 1943-1945.

314

IJSER lb) 2014

http://www.ijserorq