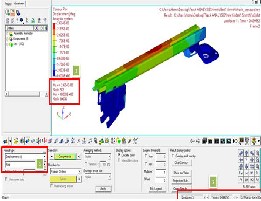

Constraints all degrees of freedoms

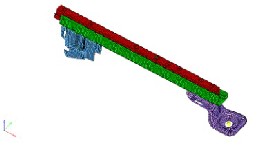

Fig. 3 constaints all degrees of freedoms Seat Track Assembly

(σt1)2+ (σt2)2 – 2 x σt1 x σt2 = [σut/ F.S] 2

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 783

ISSN 2229-5518

ANALYSIS AND OPTIMIZATION OF AUTO- MOBOILE SEAT TRACK

Akbar Basha.S, Surendra.P, Manu Ravuri, Guru Mahesh.G

Abstract—one of the objectives of automotive industries is to design quicker and more efficient vehicles, emphasizing on travelling greater distances in short interval of time. For this comfort with safety of passengers is very important, thus the design of the seating system is very important. The seat tracks provide the base to the vehicle seats and are required to perform important functions. They have physical connection to the vehicle and transfer power to the undercarriage. At the same time, they have to provide individual length adjustments possible.The Seating in an automobile is a compromise between comfort and space constraint. The compactness of the seats warrants meticulous design and is a complicated problem. Seat track assembly is the most critical criteria in the design of Seat structures in automotive industries. Amongst many parts, the seat tracks (upper and lower tracks) carry most of the load on seat structure considering human load. The aim of this project is to optimize the design of an automotive seat track subjecting to static analysis. The adopted design has thickness of seat track as 1.5mm; scope of the present work involves Finite Element Modelling of Seat track assembly using HYPERMESH. Pre-processing steps such as updating of element type, material properties, application of loads and Boundary condition is performed using HYPERMESH. The element type considered for the analysis is SHELL .Then input file (.key) compatible to LS-DYNA platform is created using HYPERMESH and same file is imported into LS-DYNA Platform. Processing is carried using LS-DYNA. The results in the form of stress and displacement are extracted using HYPER VIEW.

Index Terms— Seating System, Seat Track, Factor Of Safety, Static Analysis, Von Mises Stress

—————————— ——————————

he main objective of a good automotive seating system is not only to provide comfort but also to provide style and more importantly the safety feature. Pavan Gupta et al [1] studied

that Anti-submarine Performance of an Automotive Seating Sys- tem - A DOE study. But the system yet is sufficiently light weight to facilitate vehicle fuel economy and to minimize colli- sion stresses. D. M. Severy et al were [2] developed Collision Performance LM Safety Car. Seating system design and materials must be affordable and durable to give acceptable service life. F W Babbs et al [3] studied that the packaging of car Occupants – A British Approach to seat designs.

In addition to provisions for comfort and position ad- justments, a seating system should have adequate structure for housing safety and convenience accessories. A. W. Siegel et al [4] were developed Bus Collision Causation and Injury Patterns. The design of seat recliner is very important because during an accident or a crash, occupants tend to be thrown back against their seat backrest due to inertial forces and if the recliner is not built to withstand such an impact, it results in failure. Toshiki Nonka et al [5] studied that the Development of Ultra-High Strength Cold-Rolled Steel Sheets for Automotive Use. Sarah Smith et al [6] were developed that the Improved seat and head restraint evaluations.

————————————————

• Co-Author Manu Ravuri is currentlyworking as Asst.Professor in Dept.of

Recliner failures result in Seat-backrest twisting and collapse and which can lead to severe neck, back and spinal injuries. G. Nad- karni et al [7] also studied that Advanced High Strength Steel Strategies in Future Vehicle Structures.

Improvement in seat assembly performance is one of the most important criteria in the design of Seat structures in au- tomotive industries. Amongst many parts, the seat tracks (up- per and lower tracks) carry most of the load in seat structure considering human load. During the past years, new materials and techniques have improved the comfort while simultane- ously reducing their weight and cost. In line with the in- creased comfort and style, significant safety related improve- ment in seating system design has been given the priority.

The design is the construction of the geometric model by using CATIA software. The model may be recalled and refined by the designer at any point in the design process and it may be virtually used as an input for all other CAD/CAM functions.

In brief, the basis of the finite element method is the represen- tation of a body or a structure by an assemblage of subdivi- sions called finite elements, Figure. These elements are consid- ered interconnected at joints which are called nodal points. Simple functions are chosen to approximate the distribution or variation of the actual displacements over each finite element; such assumed functions are called displacement functions or displacement models. The unknown magnitudes or ampli- tudes of the displacement functions are the displacements (or the derivatives of the displacements) at the nodal points. Hence, the final solution will yield the approximate displace-

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 784

ISSN 2229-5518

ments at discrete locations in the body, the nodal points.

According to this theory, the failure or yielding occurs at a point in a member when the distortion strain energy ( also called shear strain energy ) per unit volume in a bi-axial stress system reaches the limiting distortion energy (i.e. distortion energy at yield point) per unit volume. Mathematically, the maximum distortion energy theory for yielding is expressed as

Constraints all degrees of freedoms

Fig. 3 constaints all degrees of freedoms Seat Track Assembly

(σt1)2+ (σt2)2 – 2 x σt1 x σt2 = [σut/ F.S] 2

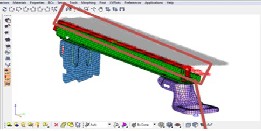

The finite element model of the seat track assembly was de- veloped using Hyper Mesh 10.0. The iges seat track model was imported to the Hyper Mesh Module. The global mesh size was set to 4mm. The faces of the component are meshed first with surface mesh option. Trias are avoided in the both upper and lower tracks, contact areas. Rotating quads and adjacent trias are avoided since the mesh gets stiffer at those locations. The following fig.1 shows the meshing model of seat track assembly.

Fig. 1 Meshing model of Seat Track Assembly

The load acting on the Seat track assembly should be considered as human weight and seat weight. i.e.

Human load = 80 kgs

Seat weight = 15 kgs

As per the Automotive Industry Standards Committee (AISC), the dynamic factor can be considered as 1.25 because of rotational effect of the parts of recliner and the ultimate load factor can be considered as 1.5

Therefore total load acting on the recliner is equal to

= (80+15) ×9.81 ×1.25 × 1.5

= 1747 N

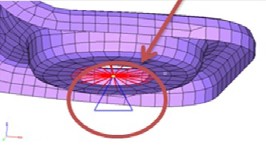

The total load of 1747 N is applied on the upper track

of the seat track assembly this load is uniform distributed by

476 nodes.

Load on each node = 1747/476 = 3.67N.

The following fig.4 shows the Load applied on seat track as-

sembly.

The following fig.2&3 shows constaints all degrees of free- doms of seat track assembly.

Constraints all degrees of freedoms

Fig. 4 Load applied

Load on each node

The MIM-316L composition (Fe-19Cr-9Ni-2Mo) is used because of its combined strength and corrosion resistance.

Fig. 2 constaints all degrees of freedoms Seat Track Assembly

Yield Strength : 230 N/mm2

Young’s modulus : 210 N/mm2

Poisson’s ratio : 0.3

Density : 7800 kg/m3

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 785

ISSN 2229-5518

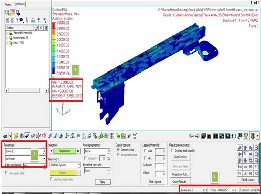

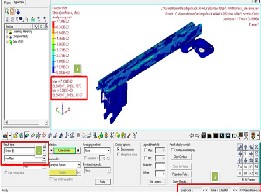

Static analysis of the seat track is carried out by using LS- DYNA software. The stress and deformation plots are shown in the following figures. The factor safety is calculated based on Von Mises Theory of Failure. The existing seat track is of thickness 1.5mm, the Von Mises stress and Displacements are recorded at different time intervals of applied load.

The following fig.5&6 shows existing seat track assembly Von

Mises stress and Displacement.

Fig. 5 Von Mises stress for seat track 1.5 mm thickness

Fig. 6 Displacaemaent of seat track 1.5 mm thickness

Table .1

Strength of the material to the maximum Von Mises Stress as per Von Mises Stress Theory of Failure.

Factor of safety for the Seat track 1.5mm thickness

= Yield Strength/Von Mises Stress

= 230/33.04

= 6.96

As factor of safety for automobile is considered in between

3-3.5 and the factor of safety for the Seat track is 6.96 the opti- mization is to be carried out.

Optimization is the fact of obtaining the best result under giv- en circumstances. In design, construction, and maintenance of any engineering system, engineers have to take many techno- logical and managerial decisions at several stages. The ulti- mate goal of all such decisions is either to minimize the effort required or to maximize the desired benefit.

As the expected factor of safety for the automobile is con- sidered as 3-3.5, therefore we need for optimization of the seat track. The optimization is done in reducing the thickness of seat track in steps i.e., 1.4mm, 1.2mm and 1mm.

Finally the required results are obtained for the seat track

1mm thickness; hence the Von Mises stress and Displacements

are recorded at different time intervals of applied load for

1mm seat track.

The following fig.7&8 shows optimised seat track assembly

Von Mises stress and Displacement.

Fig. 7 Von Mises stress for seat track 1 mm thickness

Table .1 shows the Von Mises stress and Displacement of seat

track 1.5mm thickness at different time interval.

The factor safety is calculated based on Max.Von Mises

stress 33.04 N/mm2 obtained for 0.499952sec.

The factor of safety is defined as the ratio of Yield

IJSER © 2013 http://www.ijser.org

Fig. 8 Displacaemaent of seat track 1 mm thickness

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 786

ISSN 2229-5518

Table .2

Table .2 shows the Von Mises stress and Displacement of seat

track 1mm thickness at different time interval.

The factor safety is calculated based on Max.Von Mises stress

71.34 N/mm2 obtained for 0.499952sec.

= Yield Strength/Von Mises Stress

= 230/71.34

= 3.22

As factor of safety for automobile is considered in between 3-

3.5 and the factor of safety for the Seat track for thickness 1mm

is 3.22, the seat track is in safe factor of safety zone.

Summary of Existing Seat Track

Table .3

optimization the weight of the proposed recliner assembly has come to a weight of 1.31 kg. The percentage of reduction in weight is 24.58 %

As factor of safety for automobile is considered in between 3-

3.5 and the factor of safety for the Seat track for thickness 1mm is 3.22, which is the desired value, the design is optimum.

REFERENCES

[1] Gupta, Vijay Anand R, Dhanvanti Shinde, Jayant D Joshi, Sreenivasa Rao Nunna and K.S. Ramanath, “Anti-submarine Performance of an Automotive Seating System - A DOE study”, EISAA Infosys Technologies Ltd, (2007).

[2] D. M. Severy, H. M Brink and J. D. Baird, “Collision Performance LM Safety

Car”, SAE No 670458, SAE Mid Year Meeting Chicago Illinois, (1967).

[3] F W Babbs and B C Hilton. “The packaging of car Occupants – A British Ap- proach to seat design”, Chapter 32, Seventh STAPP car crash conference, (1967).

[4] A. W. Siegel, A. M. Nahum and D. E. Runge, “Bus Collision Causation and Injury Patterns”, SAE No 710860, Proceedings of Fifteenth STAPP Car crash Conference Society of Automotive Engineers Inc, (1971).

[5] Toshiki Nonka, Koichi Goto, Hirokazu Taniguchi and Kazumasa Yamazaki “Development of Ultra-High Strength Cold-Rolled Steel Sheets for Automo- tive Use”, Nippon Steel Technical Report No. 88 (2003).

[6] Sarah Smith, David S. Zuby and Adrian K. Lund, “Improved seat and head restraint evaluations”, Marcy Edwards Insurance Institute for Highway Safe- ty United States.

[7] G. Nadkarni, N. Lazaridis and C. Horvath, “Advanced High Strength Steel

Strategies in Future Vehicle Structures”, International Automotive Body Con-

gress, Sept. 19-21, Ann Arbor MI, 2005.

Table.3 shows existing seat track assembly results.

Summary of Proposed Seat Track

Table .4

Compo- nent Name | Output Parameter | Value | Factor of Safety |

Seat track 1.5mm Thickness | Von Mises Stress | 71.34 N/mm2 | 3.22 |

Seat track 1.5mm Thickness | Weight of Seat Track | 1.31 kg | 3.22 |

Table.4 shows proposed seat track assembly results.

Optimization of seat track is done in terms of reduction in its weight by reducing the thickness of seat track, the weight of the existing seat track is found to be 1. 737 kg and after design

IJSER © 2013 http://www.ijser.org