International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 1126

ISSN 2229-5518

An excellent road network is an asset to any developing country and India in particular, as it is one of the largest countries in the world and a perfect road network would complement its development. Flexible pavements are the most commonly used form of pavements and have four component layers namely Sub-grade, Sub-base and base and surface courses, which are made up of materials like natural soils, sand, morrum etc., are proved to be costly in terms of construction as well as maintenance. The performance of plastic fines and their sticky characteristics in natural soils hampered the performance of the pavement. To reduce the impact of failures alternative materials are to be studied. In this an attempt is made by using Crushed Stone Aggregate and Crusher Dust as road component materials. Gradation mixes were prepared to meet the specifications of MORTH and subjected for various geo-technical characterizations such as gradation, compaction, strength etc. The strength characteristics of compacted crusher dust and Crushed Stone mixes have been evaluated through a series of CBR tests by varying the crusher dust and sand contents from 60% to 10%. In addition to that the suitability of compacted crusher dust as a road base and sub-base materials have been verified in accordance with MORTH specifications and identified that 20-30% in place of sand can satisfy the materials used as sub-base and base courses.

Crusher Dust, Crushed Stone Aggregate, CBR, Void Ratio.

The performance of a pavement reflects the proper functioning of the consecutive component layers of a given pavement. The design period, life of the pavement, durability and

maintenance cost can be explained by the selection of materials and their characterization. The

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 1127

ISSN 2229-5518

major component layers are Sub-base, Base courses and their functions are directly reflects the

function of Sub-grades. Earlier natural soils, sands, gravel material and Morrum can be frequently used as sub-base materials. The presence of plastic fines and their sticky characteristics hampered the performance of the pavements due to its imbibition of moistures and yields continuous plastic strains. To avoid these component layers, reduce thrust on sub- grade and to improve the drainage performance of the sub-base course and durability of the pavement as a whole alternative materials like crusher dust flyash pond ash etc, can be studied. In this an attempt is made for the utilization of mechanically stabilized crushed stone and crusher dust mixes as sub-base and base courses.

Rock flour can be advantageously used in construction of reinforced soil construction such as reinforced earth retaining walls, reinforced soil beds and reinforced flexible pavements as a fill material due to its stability, free draining nature and good frictional characteristics with synthetic reinforcement. Moorthy N.V.R. et al (2002) have studied the interaction of usage of rock flour with Geotextiles and reported the potential areas of application. Soosan et.al (2001) identified that crusher dust exhibits high shear strength and is beneficial for its use as a geotechnical material. Sridharan et.al. (2005) studied the effect of quarry Dust in highway construction that CBR and angle of shearing resistance values are steadily increased with increase the percentage of Quarry Dust. Praveen Kumar et.al(2006) conducted CBR and tri-axial tests on fly ash, coarse sand, stone dust and river bed materials for their use in the sub base materials of the flexible pavements. Shanker and Ali(1992) have studied engineering properties of rock flour and reported that the rock flour can be used as alternative material in place of sand in concrete based on grain size data. Rao, et al (1996) have reported that sand can be replaced fully with rock flour. Nagaraj T.S and Bhanu et al (2000) have studied the effect of rock dust and pebble as aggregate in cement and concrete. Wood S.A et.al reported that the quality of crushed stone dust depends on the type of parent materials. In this an attempt is made to study the effect of Crusher Dust and Crushed Stone Mixes in studying their Strength, Gradation and Compaction Characteristics.

Crusher Dust was obtained from local stone crushing plants near Anakapalli, Visakhapatnam district, Andhra Pradesh. The sample was subjected to various geotechnical

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 1128

ISSN 2229-5518

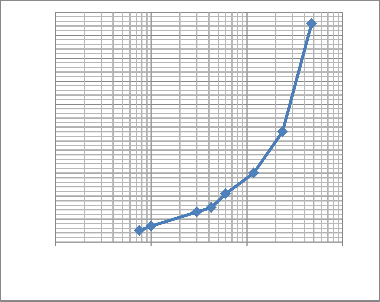

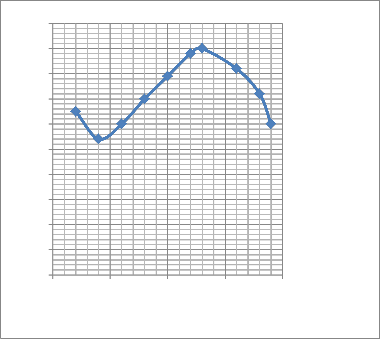

characterizations. The results are shown in table-1, and figure-1, 2. Crushed Stone Aggregate

was collected from nearby quarries of Visakhapatnam.

Property | Values |

Grain size distribution: | |

Gravel (%) | 5 |

Sand (%) | 90 |

Fines (%) | 5 |

a. Silt(%) | 5 |

b.Clay(%) | 0 |

Consistency: | |

Liquid Limit (%) | NP |

Plastic Limit (%) | NP |

I.S Classification | SP |

Specific gravity | 2.64 |

Compaction characteristics: | |

Optimum moisture content (OMC) (%) | 13 |

Maximum dry density (MDD) (g/cc) | 1.9 |

Shear parameters: | |

Angle of shearing resistance(deg) | 36 |

California bearing ratio (CBR) (%) (Soaked) | 6 |

Coefficient of Uniformity (Cu ) | 15.6 |

Coefficient of Curvature | 2.85 |

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 1129

ISSN 2229-5518

(Cc )

100

90

80

70

60

50

40

30

20

10

0

0.01 0.1 1 10

Particle Size D (mm)

Fig-1 Gradation curve of Crusher Dust

2

1.9

1.8

1.7

1.6

1.5

1.4

1.3

1.2

1.1

1

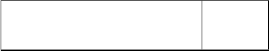

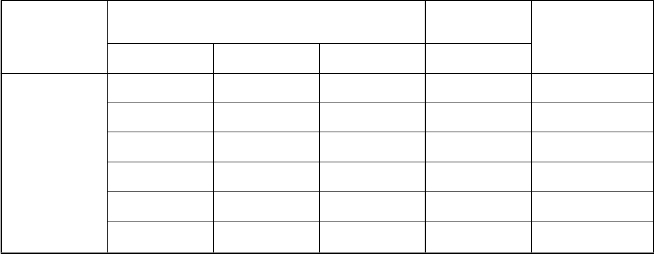

0 5 10 15 20 moisture content(%)

OMC-13% MDD-1.9g/cc

Table 1 Fig 2 Compaction Curve of Crusher Dust

From the physical characteristics it is observed that crusher dust is a grey color fine aggregate consisting of medium to fine sand size particles and of angular shape with rough

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 1130

ISSN 2229-5518

surface texture. From the consistency data it is non-plastic and incompressible. From the

compaction curve it can be seen that crusher dust attains higher densities with wider variation in moisture content and also increase in workability at higher moisture contents.

Crushed stone aggregate was obtained from nearby stone crusher plants of

Visakhapatnam. After brushing the aggregate it was washed and dried. A set of sieves such as

53mm, 26.5mm, 9.5mm etc. have identified for the gradation of stone aggregate and for the fine aggregate 4.75mm, 2.36mm, 0.425mm, 0.075mm sizes were identified. Various percentages of stone aggregate were added to the Crusher Dust as listed below and also the percentage of Crusher Dust.

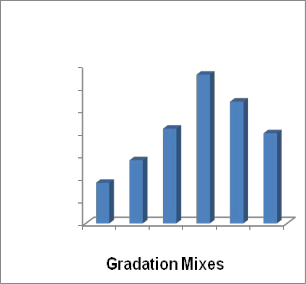

Stone aggregate mixed with Crusher Dust was graded to various gradation mixes in accordance with MORTH specifications and named as G1, G2, G3, G4, G5, and G6.

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 1131

ISSN 2229-5518

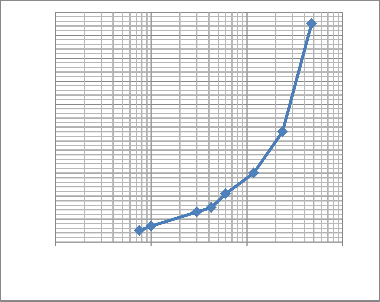

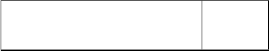

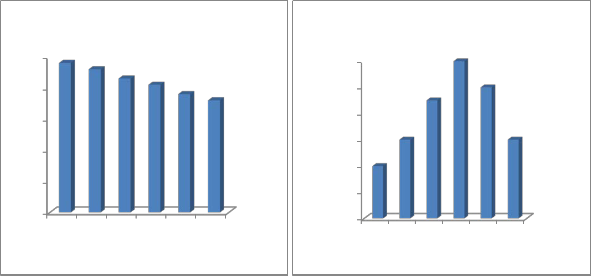

The gradations mixes were subjected to various geotechnical characterizations such as gradation,

compaction, strength (CBR), void ratio etc. The results are listed below table-3 and fig- 3,4,5,6.

CRUSHED STONE AGGREGATE + CRUSHER DUST Gradation (percentage finer) | ||||||

Gradation Sieve Sizes (mm) | G1 | G2 | G3 | G4 | G5 | G6 |

Gradation Sieve Sizes (mm) | (CSA40- CD60%) | (CSA50- CD50%) | (CSA60- CD40%) | (CSA70- CD30%) | (CSA80- CD20%) | (CSA90- CD10%) |

53 | 100 | 100 | 100 | 100 | 100 | 100 |

26.5 | 90 | 90 | 80 | 80 | 80 | 70 |

9.5 | 80 | 70 | 60 | 60 | 50 | 40 |

4.75 | 55 | 46 | 37 | 28 | 20 | 10 |

2.36 | 30 | 24 | 19 | 15 | 10 | 5 |

0.425 | 10 | 8 | 6 | 5 | 3 | 2 |

0.075 | 3 | 3 | 2 | 2 | 1 | 1 |

Compaction Characteristics | ||||||

OMC (%) | 5.8 | 5.4 | 4.8 | 4.5 | 4.0 | 3.6 |

MDD (g/cc) | 2.12 | 2.15 | 2.18 | 2.22 | 2.2 | 2.16 |

Strength | ||||||

CBR Soaked | 18 | 28 | 42 | 66 | 54 | 40 |

Void Ratio (e) | 0.28 | 0.27 | 0.26 | 0.22 | 0.27 | 0.3 |

Specific Gravity (Gc ) | 2.71 | 2.73 | 2.75 | 2.78 | 2.8 | 2.82 |

Voids(%) | 21.8 | 21.2 | 20.7 | 20.1 | 21.4 | 23.4 |

Table 3

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 1132

ISSN 2229-5518

To know the compaction characteristics of the designated gradation mixes G1, G2, G3, G4, G5 and G6 Modified proctor compaction test was performed as per IS 2720-Part 8:1983 and the results are shown in table- 3 and fig- 3&4. From the compaction test data, it is identified that maximum dry densities values are increasing with decrease in percentage of crusher dust with respect to Crushed Stone aggregate upto 30-20% and decreasing i.e. 2.12 g/cc to 2.22 g/cc and

2.22 g/cc to 2.16 g/cc respectively. Similarly it is also identified that OMC values are decreasing with decrease in percentage of crusher dust i.e., from 5.8 to 3.6%. Decrease in optimum moisture contents can be explained as at the higher percentages of crusher dust more water is needed to coat the crusher particles as it depends on nature, size and shape of crusher dust particles and at lower percentages less water is required due to less quantities of crusher dust particles available in the mixes. Attainment of lower and higher maximum dry densities can be explained in the following way. At higher percentages of crusher dust (50-60%) with respect to crushed stone aggregate more number of voids are opened up and all these not properly filled by crusher dust particles forming honey combed structures with higher void ratios, at lower percentages of crusher dust(<20%) opening up of voids are taking place and crusher dust particles are not sufficient to fill up these voids resulting in development of honey combed structures. Effective replacement attained at 20-30% of crusher dust is due to filling up of formed voids partly with smaller size coarse aggregate and remaining by crusher dust particles responsible for attainment of higher densities. For a range of 20-30% of crusher dust addition, the gradation mixes became

densely compacted with attainment of less void ratios and high densities.

OMC (%)

MDD (g/cc)

5

4

3

2

1

0

G1 G2 G3 G4 G5 G6

Gradation Mixes

2.22

2.2

2.18

2.16

2.14

2.12

2.1

G1 G2 G3 G4 G5 G6

Gradation Mixes

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 1133

ISSN 2229-5518

Fig-3 Fig-4

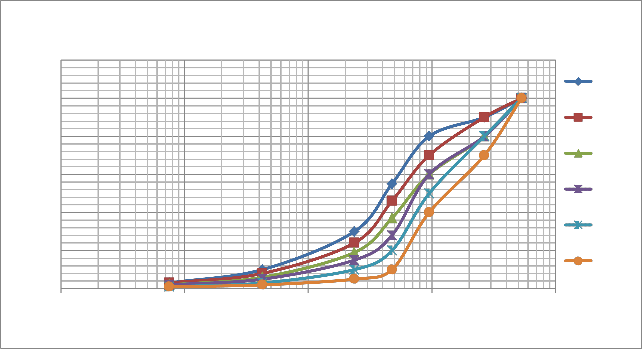

For the above gradation mixes G1, G2, G3, G4, G5 and G6 particle size distribution curves and their results were developed and these are shown in table-4 and fig-5.

120

100

80

60

40

20

Crushed stone aggregate+ Crusher Dust

G1

G2

G3

G4

G5

G6

0

0.01 0.1 1 10 100

Fig-5

Crushed Stone aggregate + Crusher dust | ||||||

Particle Size(mm) | G1 (CSA40- CD60%) | G2 (CSA50- CD50%) | G3 (CSA60- CD40%) | G4 (CSA70- CD30%) | G5 (CSA80- CD20%) | G6 (CSA90- CD10%) |

D10 | 0.43 | 0.59 | 0.94 | 1.5 | 2.3 | 4.7 |

D15 | 0.8 | 1 | 1.6 | 2.5 | 3.5 | 5.6 |

D30 | 2.36 | 2.9 | 4 | 5.1 | 6.6 | 8.2 |

D60 | 4.75 | 6.5 | 9.5 | 10 | 13 | 19 |

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 1134

ISSN 2229-5518

Cu | 11.04 | 11.01 | 10.1 | 6.67 | 5.65 | 4.04 |

Cc | 2.72 | 2.19 | 1.79 | 1.73 | 1.45 | 0.75 |

Table-4 Grain size parameters

From the test data it is observed that increase in the percentage of crusher dust decreases Cu and Cc values i.e. Cu values from 11.04 to 4.04 and C c values from 2.72 to 0.75 respectively. At higher percentage of crusher dust with respect to aggregate a wider variation in range of particles were observed these may lead to higher values of Cu and Cc whereas at lower percentage of crusher dust lesser variation in range of particles were observed and these may lead to lower values of Cu and Cc and make the mixes honey combing and less dense. In between

20 and 30 % of crusher dust the concerned gradation mixes try to maintain well graded

conditions with dense packing in addition to shape and size of crusher dust particles may also responsible for generation of these values.

Dried Crushed Stone aggregate and crusher dust has taken to the required proportions for the designated mixes G1 to G6 and compacted at their maximum dry densities in the CBR moulds and soaked for 4 days. After completion of the required soaking period the samples were tested in the CBR test apparatus at a strain rate of 1.25 mm/min as per IS 2720-Part 16: 1987. From the test results of CBR the following identifications were made. As the percentage of crusher dust decreases CBR values are increasing. Maximum values were obtained at 30% dosage i.e 66, a little decrease was observed from 30-20%. Considering the other parameters such as void ratio, percentage voids and maximum dry densities into account, it is identified that a dosage of 20-30% crusher dust make the gradation mixes dense and offer more shear strength

due to mobilization of friction resistance under compression.

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 1135

ISSN 2229-5518

CBR

70

60

50

40

30

20

10

0

G1 G2 G3 G4 G5 G6

Fig-6

Comparing gradation mixes G1 to G6, with the gradation mixes of MORTH sub-base courses it is identified that at higher percentages of crusher dust these mixes are nearing to Grade-II and Grade-III (Section 400-1) of close graded mixes and at lower percentages of crusher dust these are nearing to Grade-I. It can also seen that the majority of the gradation mixes satisfying the Grades of coarse graded granular sub-base materials (Section 400-2). Hence, the gradation mixes of crusher dust and Crusher stone aggregate with an addition of 20-30% with respect to Crusher stone Aggregate attaining CBR value greater than 50 can be recommended as Base course and Sub-base course materials and the mixes having CBR greater than 30 can be used as Sub-base material.

Sizes of crusher dust grains are mostly of medium to fine sand sizes uniform gradation of particles and of slightly lower specific gravities attained closer packing with respect to crusher stone aggregates resulting higher densities and CBR values can be used as Sub-base base courses in flexible payment constructions.

IJSER © 2013 http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 4, Issue 11, November-2013 1136

ISSN 2229-5518

1. IS 2720: Part 4: 1985 Methods of Test for Soils - Part 4: Grain Size Analysis.

2. IS 2720: Part 8: 1987 Methods of Test for Soils - Part 8: Determination of water Content and Dry Density Relation Using Heavy Compaction.

3. IS 2720: Part 16: 1987 Methods of Test for Soil – Part 16 : Laboratory Determination of

CBR.

4. MORTH specification For Road and Bridge Works, published by IRC 2001.

5. Moorthy, N.V.R et.al (2002) “potential of rock flour for use in reinforced soil construction”, journal of Southeast Asian Geotechnical society, Vol.88, pp.47-50.

6. Nagaraj T.S. 2000. Proportioning Concrete Mix with Rock Dust as Fine Aggregate. CE

and CR Journal. pp. 27-31.

7. Praveen Kumar, Satish Chandra and Vishal, R(2006) “comparative study of different

Sub-base material journal of materials” in civil engineering vol 18(4) 576-580.

8. Rao, G.T and Andal, T(1996), “ A Study on Behaviour of Concrete With Stone Sand Replacing River Sand”, National Conference on Alternate Construction Materials in Civil Engineering”, Hamirpur, pp. 196-201.

9. Soosan, T.G., Jose, B.T. and Abraham, B.M.(2001) Use of Crusher dust in embankment

and highway construction, Proceedings of Indian Geo-Technical Conference, December, Indore, pp.274-277.

10. Sridharan, A. And Soosan, T.,G. (2005),”utilization of crusher dust to improve the geotechnical properties of soil in highway construction”, Canadian Geotechnical Journal, Vol. 28, pp. 391-400.

11. Shankar, N.B and Ali, Md (1992), “Engineering Properties of Rock Flour”, National

Conference on Cement and Building Materials from Industrial Waste, pp.167-172.

12. Wood S.A and Mareck C.R(1993) Recovery and utilization of quarry by-products for construction of highway facilities, federal administration, Denver, Colorado.

IJSER © 2013 http://www.ijser.org