The research paper published by IJSER journal is about A REVIEW FOR CHARACTERIZATION OF SILICA FUME AND ITS EFFECT ON CONCRETE WITH POZZOLONIC PORTLAND CEMENT 1

ISSN 2229-5518

A REVIEW FOR CHARACTERIZATION OF SILICA FUME AND

ITS EFFECT ON CONCRETE WITH POZZOLONIC PORTLAND CEMENT

Ajay Verma1, Dr Rajeev Chandak2, R.k.Yadav3

1. M.E. scholar structural engineering Govt. Engineering College Jabalpur INDIA

2. Professor Civil engineering dept. Govt. Engineering College Jabalpur INDIA

3. Associate Professor Civil engineering dept. Govt. Engineering College Jabalpur INDIA

Corresponding email :aj8104@rediffmail.com

Concrete is a most widely used building material which is a mixture of Cement, Sand, Coarse aggregate and water. Nowadays high strength and high performance concrete are widely used in many civil engineering works. Mineral admixtures (fly ash, silica fume and slags) are usually added to concrete in larger amounts to enhance the properties of concrete. Silica fume is much fined separated silica obtained as a by-product in industry Micro silica or Silica fume is very fine non crystalline material. Silica fume is produced in electric arc furnace as a by product of the production of elemental silicons or alloys containing silicon . It is used as an admixture in the concrete mix and it has significant effects on the properties of the resulting material. To study effect of silica fume on strength is the main objective of this work. Yhis paper deals with the influence of strength with addition of silica fume as an admixture to the concrete in various proportion 5%,10%,15%, and 20%by weight of cement. Concrete containing microsilica showed considerable increase in strength.

Keywords: Silica fume, mineral admixture, compressive strength

IJSER © 2013 http://www.ijser.org

The research paper published by IJSER journal is about A REVIEW FOR CHARACTERIZATION OF SILICA FUME AND ITS EFFECT ON CONCRETE WITH POZZOLONIC PORTLAND CEMENT 2

ISSN 2229-5518

INTRODUCTION

Nowadays concrete is being used for wide variations of purpose is make it suitable for different conditions. Admixture are used to modified the properties of ordinary concrete so as to make it more suitable for any situations. Silica fume or microsilica is an important material that is used

as an artificial pozzolanic admixture. Silica fume contribute to the strength properties of concrete

by being very fine pozzolanic material and also creating dense packing and pore filler of cement paste.

silica fume is a by product resulting from reduction of High purity quartz with coal or coke and wood chips in an electric arc furnace during production of silicon metal or ferrosilicon alloys. Nowadays whole World is facing a major problem of environmental pollution. Nowadays engineers and scientists are trying to increase the strength of concrete by adding the some other cheap and waste material as a partial replacement of cement or as a admixture fly ash, micro silica, steel slag etc are the few examples of these types of materials.

MATERIALS AND EXPERIMENT METHOD Portland Pozzolana Cement (PPC)

The Portland Pozzolana Cement is a kind of Blended Cement which is produced by either intergrinding of OPC clinker along with gypsum and pozzolanic materials in certain proportions or grinding the OPC clinker, gypsum and Pozzolanic materials separately and thoroughly blending them in certain proportions.

Pozzolana is a natural or artificial material containing silica in a reactive form. It may be further discussed as siliceous or siliceous and aluminous material which in itself possesses little, or no cementitious properties but will in finely divided form and in the presence of moisture, chemically react with calcium hydroxide at ordinary temperature to form compounds possessing cementitious properties. It is essential that pozzolana be in a finely divided state as it is only then that silica can combine with calcium hydroxide (liberated by the hydrating Portland Cement) in the presence of water to form stable calcium silicates which have cementitious properties.

Silica fume

Silica fume, also known as microsilica, is an amorphous (non-crystalline) polymorph of silica dioxide. It is an ultrafine powder collected as a by-product of the silicon and ferro-silicon alloy production and consists of spherical particles with an average particle diameter of 150 nm. The

main field of application is as pozzolanic material for high performance concrete.

IJSER © 2013 http://www.ijser.org

The research paper published by IJSER journal is about A REVIEW FOR CHARACTERIZATION OF SILICA FUME AND ITS EFFECT ON CONCRETE WITH POZZOLONIC PORTLAND CEMENT 3

ISSN 2229-5518

Silica fume is an ultrafine airborne material with spherical particles less than 1 μm in diameter, the average being about 0.1 μm. This makes it approximately 100 times smaller than the average cement particle. The unit weight, or bulk density, of silica fume depends on the metal from

which it is produced. Its unit weight usually varies from 130 to 430 kg/mᶾ. The specific gravity of silica fume is generally in the range of 2.20 to 2.5. In order to measure the specific surface area of silica fume a specialized test called the “BET method” or nitrogen adsorption method must be used. Based on this test the specific surface of silica fume typically ranges from 15,000 to 30,000 mᶾ/kg.

EXPERIMENTAL DETAILS

The following materials were used for experiment

Portland pozzolana cement conforming to IS 1489-1991

Graded fine aggregates :Local clean river sand

Graded coarse aggregates: locally available well graded aggregates of normal size greater than

4.75mm and less than 10mm having a fineness modulus of 2.75

Test Procedure and results:-

150x150x150 mm concrete cubes were cast using 1:1.5:3 mix proportion with w/c ratio of 0.50

Specimen with Portland pozzolana cement with various silica fume level 0%, 5%, 10%, 15%

were cast, during moulding the cubes were mechanically vibrated after moulding the concrete blocks were demoulded and subjected to curing in water for 7days,14days 28days.

The specimen were tested for compressive strength using a compression testing machine of 200

KN capacity.

Results

IJSER © 2013 http://www.ijser.org

The research paper published by IJSER journal is about A REVIEW FOR CHARACTERIZATION OF SILICA FUME AND ITS EFFECT ON CONCRETE WITH POZZOLONIC PORTLAND CEMENT 4

ISSN 2229-5518

Table-1

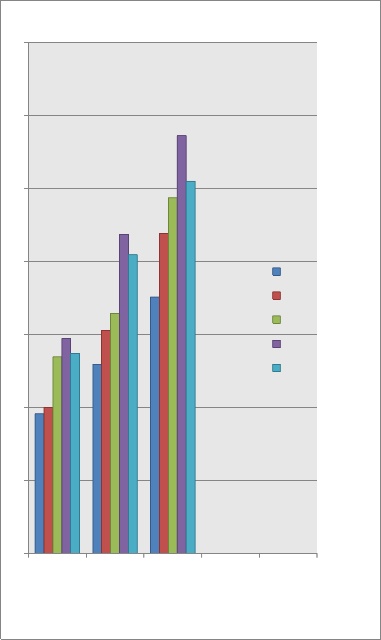

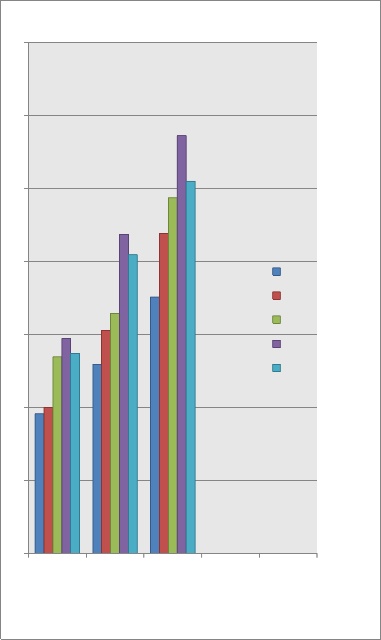

Mix Description | Plain | 5 SF | 10 SF | 15 SF | 20 SF |

% adding of silica fume | 0 % | 5 % | 10% | 15 % | 20 % |

7 Days | 23.2 | 28.4 | 32.1 | 33.2 | 32.1 |

14 Days | 28.7 | 30.5 | 34.4 | 37.4 | 36.3 |

28 Days | 34.7 | 43.8 | 45.7 | 48.3 | 45.5 |

IJSER © 2013 http://www.ijser.org

The research paper published by IJSER journal is about A REVIEW FOR CHARACTERIZATION OF SILICA FUME AND ITS EFFECT ON CONCRETE WITH POZZOLONIC PORTLAND CEMENT 5

ISSN 2229-5518

70

60

50

40

0% silica fume

5%silica fume

10% silica fume

30

15 silica fume

20%SILICA

20

10

0

7 day 14 day 28 day

Figure-1

It has been cleared from above results that addition of micro silica increase the strength of concrete 26%-38%

IJSER © 2013 http://www.ijser.org

The research paper published by IJSER journal is about A REVIEW FOR CHARACTERIZATION OF SILICA FUME AND ITS EFFECT ON CONCRETE WITH POZZOLONIC PORTLAND CEMENT 6

ISSN 2229-5518

CONCLUSIONS

The variation of compressive strength of the concrete with the addition of 0%,5%,10%, 20% silica fume by weight of cement as an admixture isshown in figure 1,based on these experimental results the following conclusions have been drawn

1. As we add silica fume as an admixture in the concrete in different percentage of cement by weight, the strength of concrete increases substantially for concrete containing PPC

2. The optimum increase in the strength of M 25 cocnrete was found on 15% addition of silica fume by weight of cement.

3. The increase in compressive strength was 25% to 40% for concrete containing PPC

4. Silica fume is much cheaper then the cement therefore it is very important from economical point of view

1. Silica fume manual by Oriental Trexim Pvt. Ltd.

2. Concrete Technology by M.S.Shetty , puvlished by S CHAND and company pvt ltd New

Delhi.

3. Ha-Won Song, Seung-Woo Pack, Sang-Hyeok Nam, Jong-Chul Jang and Velu Saraswathy “Estimation of the permeability of silica fume cement concrete” Construction and building material vaolume 24 march 2010 page 315-321

4. Abdullah A. Almusallam, Hamoud Beshr, Mohammed Maslehuddin, Omar S.B. Al-

Amoudi,, “Effect of silica fume on the mechanical properties of low quality coarse aggregate concrete”, Cement & Concrete Composites 26 (2004) 891–900.

5. IS 456-2000 Plain and reinforced concrete code of practice

IJSER © 2013 http://www.ijser.org

The research paper published by IJSER journal is about A REVIEW FOR CHARACTERIZATION OF SILICA FUME AND ITS EFFECT ON CONCRETE WITH POZZOLONIC PORTLAND CEMENT 7

ISSN 2229-5518

6. M.V. Krishna rao,P Ratish kumar,Azhar M. Khan. “ A study on the influence of curing on the strength of a standard grade concrete mix” Architecture and Civil Engineering Vol. 8, No 1, 2010, pp. 23 – 34 hyderabad India.

7. S. Bhanjaa,, B. Sengupta “Influence of silica fume on the tensile strength of concrete”

Cement and Concrete Research 35 (2005) 743–747

8. IS 10262 -2009 Indian Standard recommended guide lines for concrete mix design

9. IS 383-1970 code for properties of aggregates.

10. ACI report 234R-96 (reapproved 2000)

IJSER © 2013 http://www.ijser.org